Yaşam süresini anlamak CO2 lazer tüpü kullanan herkes için çok önemlidir. lazer kesici veya lazer kesim makinesi. Yaşam süresi CO2 lazer tüpü ekipmanınızın verimliliğini ve maliyet etkinliğini doğrudan etkiler. Lazer tüpü ekipmanınızın kalbidir lazer makinesi, üretilmesinden sorumlu olan lazer ışını kesim veya kazıma işlemini gerçekleştirir. Ne kadar süreceğini bilmek lazer tüpü tipik olarak uzun sürdüğünü ve hizmet ömrü birçok faktörden etkilenmesi, ekipmanınızın bakımını daha iyi yapmanıza yardımcı olabilir. lazer gücü, ve maliyetli arıza sürelerini ve değişimleri azaltır.

Lazer Teknolojisine Giriş

Lazer teknolojisi, endüstrilerin kesme, kazıma ve işaretleme işlerine yaklaşımını değiştirmiştir. Bu yeniliğin merkezinde, çok çeşitli uygulamalarda kullanılan güçlü lazer ışınını üreten lazer tüpü yer almaktadır. İster bir üretim tesisinde ister küçük bir atölyede bir lazer kesim makinesiyle çalışıyor olun, lazer tüplerinin işlevini ve bakımını anlamak, tutarlı sonuçlar elde etmenin ve ekipmanınızın ömrünü en üst düzeye çıkarmanın anahtarıdır.

Lazer tüpünüzün doğru bakımı, ara sıra yapılan temizlikten daha fazlasını içerir. Aynaların incelenmesi, soğutma sisteminin doğru çalıştığından emin olunması ve makinenin önerilen sıcaklık aralığında tutulması gibi düzenli bakım rutinleri, tüpün ömrünü uzatmak ve genel performansı korumak için çok önemlidir. Bu uygulamalara öncelik vererek lazer kesim makinenizin verimli çalışmasını, hassas kesimler yapmasını ve yıllarca güvenilir kalmasını sağlayabilirsiniz.

Lazer Kesicileri Anlamak

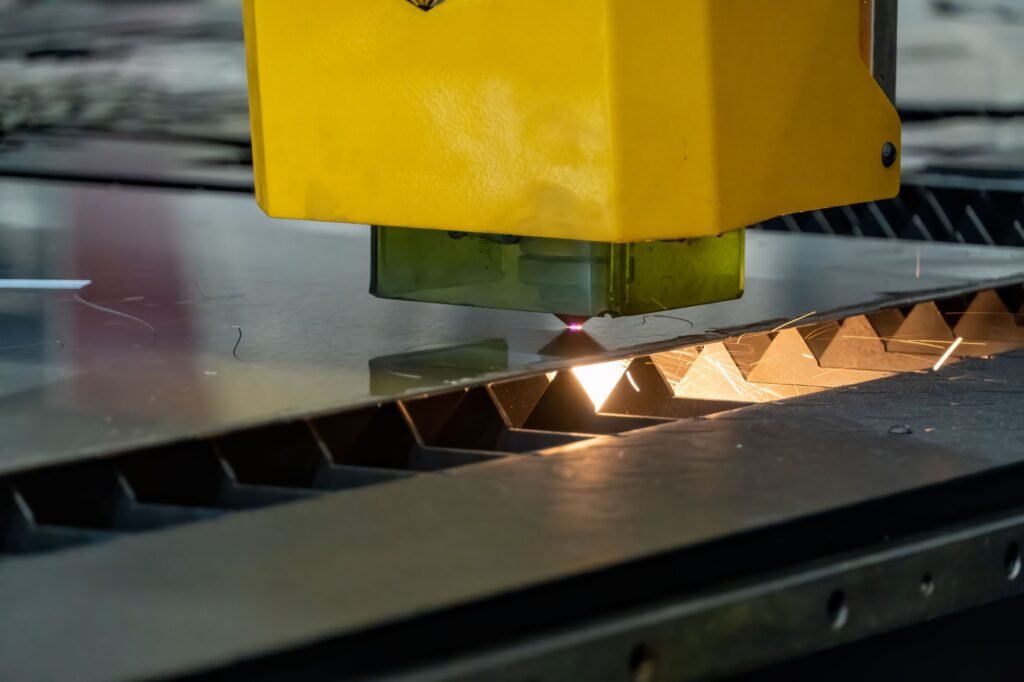

Lazer kesiciler veya lazer kesim makineleri, metaller ve plastiklerden ahşap ve kompozitlere kadar çeşitli malzemeleri kesmek, kazımak veya işaretlemek için odaklanmış bir lazer ışını kullanan hassas araçlardır. Her lazer kesicinin merkezinde, tipik olarak cam veya metalden yapılmış olan ve asıl kesimi yapan lazer ışınını üretmekten sorumlu olan lazer tüpü bulunur.

Bir lazer kesicinin performansı birbirine bağlı birkaç bileşene bağlıdır. Güç kaynağı lazer tüpüne enerji verirken, kontrol sistemi kesme hızı, çıkış gücü ve sıcaklık aralığı gibi kritik parametreleri yönetir. Bu unsurların her biri, verimli çalışma ve yüksek kaliteli sonuçlar sağlamak için uyum içinde çalışmalıdır. Cam tüpün durumunu kontrol etmek, çıkış gücünü izlemek ve sistemi temiz tutmak gibi düzenli bakım, makinenin genel performansını korumaya yardımcı olur ve bileşenlerinin ömrünü uzatır. Kullanıcılar, bu parçaların nasıl etkileşime girdiğini anlayarak lazer kesicilerini hem hassasiyet hem de uzun ömürlülük için optimize edebilirler.

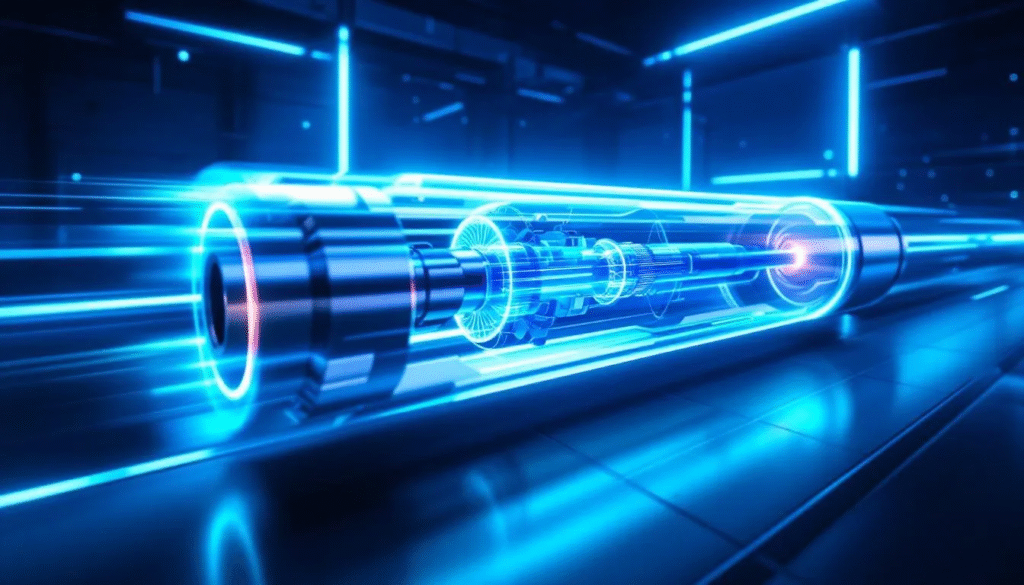

CO2 Lazer Tüpü nedir?

A CO2 lazer tüpü mühürlü bir cam tüp karışımı ile doldurulmuş karbondioksit, nitrojen molekülleri ve diğer gazlar. Elektrik bu gaz karışımından geçtiğinde, molekülleri uyarır ve güçlü bir gaz üretir. lazer ışını kızılötesi spektrumda. CO2 lazer tüplerinin sonunda gazı biter ve bu da kullanım ömürlerini etkiler. Bu süreç, gaz karışımını uyarmak ve lazer çıktısını oluşturmak için elektrik enerjisinin kullanıldığı lazer tüpü uyarma yöntemi olarak bilinir. Bu ışın daha sonra çeşitli malzemeleri hassas bir şekilde kesmek veya kazımak için aynalar ve lensler aracılığıyla yönlendirilir.

Bu cam tüp dayanıklı bir muhafaza içinde metal gövde dış hasarlardan korumak için. Bu lazer tüpü’istikrarlı bir şekilde sürdürme yeteneği çıkış gücü büyük ölçüde dahili gaz karışımına ve bütünlüğüne bağlıdır. cam ve diğer bileşenler.

Tipik CO2 Lazer Tüpü Ömrü: Lazer Tüpü Ömrünü Etkileyen Faktörler

Bu yaşam süresi bir CO2 lazer tüpü tipik olarak 1.000 ila 3.000 saatlik çalışma arasında değişir. Çoğu CO₂ lazer tüpü, kullanıma ve bakıma bağlı olarak 1.500 ila 3.000 saat arasında dayanır. Ancak bu, aşağıdakilere bağlı olarak önemli ölçüde değişebilir çeşitli faktörler, Kullanım, tüpün kalitesi, çalışma koşulları ve ekipmanın bakımının ne kadar iyi yapıldığı da dahil olmak üzere.

İçinde çoğu vaka, düşük kaliteli tüpler veya maksimum sıcaklıkta çalıştırılanlar güç sürekli olarak önemli ölçüde zayıflamış bir hizmet deneyimleyecektir hayat. Öte yandan, aşağıdaki gibi yüksek kaliteli tüpler Reci tüpleri dayanıklılıkları ve daha uzun ömürlü olmaları ile bilinir. hayat.

CO2 Lazer Tüp Ömrünü ve Hizmet Ömrünü Etkileyen Faktörler

Çeşitli faktörler aşağıdakileri etkileyebilir yaşam süresi ve genel olarak performans senin lazer tüpü. Lazer tüpünün bakımı düzgün yapılmazsa veya sınırlarının ötesine zorlanırsa, daha fazla çalışması gerekir, bu da aşınmayı hızlandırabilir ve ömrünü kısaltabilir.

Çalışma Gücü ve Kesme Hızının CO2 Lazer Tüp Ömrü Üzerindeki Etkisi

Çalıştırmak lazer makinesi yüksekte güç ayarlarında veya çok yüksek hızda kesmeye zorlayarak kesme hızları fazla üretebilir ısı, bu da daha yüksek sıcaklıklar lazer tüpü içinde. Bu ısı, lazer tüpünün aşınmasını ve yıpranmasını hızlandırabilir. cam tüp ve azaltmak hizmet ömrü. Dengeleme lazer gücü ve kesme hızı kesilen malzemeye göre ayarlanması çok önemlidir.

Sıcaklık Aralığı, Soğutma Sistemi ve CO2 Lazer Tüpü Ömrü

Bakım lazer tüpü içinde uygun sıcaklık aralığı hayati önem taşır. Lazer tüpü, içindeki gaz karışımını uyarmak için elektrik enerjisi kullanarak çalışır ve bu da istikrarlı performans için gereklidir. Aşırı ısınma, erken tüp arızasına neden olan en büyük etkenlerden biridir. Tavsiye edilenin dışında çalıştırmak sıcaklık aralığı tüpün aşırı ısınmasına ve daha hızlı bozulmasına neden olabilir. İyi işleyen bir soğutma si̇stemi̇ ısının etkili bir şekilde dağıtılmasına yardımcı olarak istikrarlı çalışma sağlar ve yaşam süresi.

Gaz Kalitesi, Çevre Koşulları ve Lazer Tüpü Ömrü

Karışımı karbondioksit, azot molekülleri ve tüpün içindeki diğer gazlar yüksek kalitede ve doğru şekilde dengelenmiş olmalıdır. Zamanla bu gaz karışımı, özellikle de tüp kirletici maddelere veya yanlış kullanıma maruz kalırsa bozulabilir.

Yüksek nem ve toz aşağıdakilere zarar verebilir cam tüp ve dahili bileşenler. Kirli optikler ve kirlenmiş aynalar lazer ışını’nin verimliliğini azaltır ve düzensiz aşınmaya neden olabilir. Tutmak lazer kesim makinesi temiz ve kontrollü bir ortamda gerçekleştirilmesi esastır.

CO2 Lazer Tüpünün Ömrünü Uzatmak için Bakım ve Doğru Bakım

Temizlik de dahil olmak üzere düzenli bakım optik, kontrol etmek soğutma si̇stemi̇, ve incelenmesi lazer tüpü aşınma belirtilerine karşı korunması, kullanım ömrünü uzatmanın anahtarıdır. tüp’s hizmet ömrü. Soğutma sisteminin bir alarm özelliği ile bakımı, yetersiz soğutma veya su akışı nedeniyle oluşabilecek hasarları önleyebilir. Bakımın ihmal edilmesi erken arızalara ve maliyetli değişimlere yol açabilir. Bir lazer tüpünün değiştirilmesi zaman alıcı bir işlem olabilir, bu nedenle düzenli bakım bu rahatsızlığı önlemeye yardımcı olur.

Maksimum Verimlilik için Lazer Makinesi Optimizasyonu

Lazer makinenizden maksimum verim elde etmek, akıllı ayarlar ve özenli bakımın bir kombinasyonunu gerektirir. Kesme hızını, çıkış gücünü ve sıcaklık aralığını çalıştığınız malzemeye uygun hale getirerek işe başlayın. Bu sadece kesimlerinizin kalitesini artırmakla kalmaz, aynı zamanda lazer tüpü üzerindeki gereksiz gerilimi de azaltır.

Düzenli bakım da aynı derecede önemlidir. Lazer ışınının güçlü ve odaklı kalmasını sağlamak için aynaları ve lensleri sık sık temizleyin. Aşırı ısınmayı önlemek için soğutma sistemini kontrol edin ve tutarlı performansı korumak için gaz seviyelerini izleyin. Reci tüpleri gibi yüksek kaliteli bileşenlere yatırım yapmak lazer makinenizin güvenilirliğini ve verimliliğini daha da artırabilir. Bu en iyi uygulamaları izleyerek lazer tüpünüzün ömrünü uzatabilir, arıza süresini azaltabilir ve lazer kesim operasyonlarınızın sorunsuz çalışmasını sağlayabilirsiniz.

Farklı Malzemelerin Kesilmesi: CO2 Lazer Tüp Ömrü Üzerindeki Etkisi

Lazer makinenizle kestiğiniz malzemenin türü, CO2 lazer tüpünüzün ömrü üzerinde önemli bir etkiye sahip olabilir. Akrilik ve ahşap gibi malzemeler kesim sırasında genellikle lazer tüpü ve optikler üzerinde birikerek aşınmanın artmasına ve performansın düşmesine neden olabilecek ince döküntü ve kalıntılar üretir. Öte yandan metaller, lazer tüpünü zorlayabilecek ve uzun ömürlülüğünü etkileyebilecek yoğun ısı üretebilir.

Bu etkileri en aza indirmek için kesme hızınızı, çıkış gücünüzü ve sıcaklık aralığınızı elinizdeki malzemeye göre ayarlamanız önemlidir. Aynaları ve lensleri temizlemek ve gaz seviyelerini kontrol etmek gibi düzenli bakımlar, birikmeyi önlemeye yardımcı olur ve lazer tüpünün optimum koşullarda çalışmasını sağlar. Makinenizin ayarlarını ve bakım rutinlerini kestiğiniz belirli malzemelere uyarlayarak lazer tüpünüzün ömrünü önemli ölçüde uzatabilir ve çeşitli projelerde yüksek kaliteli sonuçlar elde edebilirsiniz.

CO2 Lazer Tüpünüzün Ömrünü Nasıl Uzatabilirsiniz?

En üst düzeye çıkarmak için CO2 lazer tüpü kullanım ömrü ve optimum seviyede tutmak lazer kesim performansı için aşağıdakileri uygulayın En iyi ipuçları:

Lazer kesim sürecini optimize etmek yalnızca verimliliği ve kenar kalitesini artırmakla kalmaz, aynı zamanda CO2 lazer tüpünüzün ömrünü uzatmaya da yardımcı olur.

- Önerilen güç ve hız ayarları dahilinde çalıştırın: Çalıştırmaktan kaçının lazer makinesi sürekli olarak tam güçte. Ayarları kestiğiniz malzemeye göre yapın, örneğin akrilik, metal veya ahşap.

- Uygun sıcaklık aralığını koruyun: Verimli bir soğutma si̇stemi̇ tutmak için lazer tüpü sıcaklığı sabit tutar ve aşırı ısınmayı önler.

- Optikleri temiz tutun: Önlemek için aynaları ve mercekleri düzenli olarak temizleyin kirli optikler zayıflatabilecek lazer ışını ve kesme hassasiyetini azaltır.

- Çevreyi kontrol edin: Koruyun lazer kesim makinesi zarar görmesini önlemek için yüksek nem ve tozdan cam tüp ve diğer bileşenler.

- Yüksek kaliteli tüpler ve gazlar kullanın: Saygın yatırımlar Reci tüpleri ve gaz karışımının saf olmasını sağlamak önemli ölçüde iyileştirebilir hizmet ömrü.

- Düzenli bakım gerçekleştirin: Aşınma ve yıpranmanın erken belirtilerini tespit etmek ve bunları derhal ele almak için rutin kontroller ve servisler planlayın.

- Akımı bir miliampermetre ile izleyin: Bir miliampermetre kullanmak, kullanıcıların lazer tüpüne verilen akımı izlemelerine ve aşırı yüklenmesini önlemelerine olanak tanır.

Lazer sisteminizin bakımı hakkında daha ayrıntılı tavsiyeler için şu adresi ziyaret edebilirsiniz Rabbit Laser USA'in CO2 lazer tüp ömrünü uzatma kılavuzu.

CO2 Lazer Tüpünüzü Ne Zaman Değiştirmelisiniz? Lazer Tüpünüzün Değiştirilmesi Gerektiğini Gösteren İşaretler

Tüm önlemlere rağmen, her lazer tüpü sonunda yıpranacaktır. CO2 lazer tüpleri genellikle tükendiklerinde veya yıprandıklarında değiştirilir. İşaretler sizin lazer tüpü değişim ihtiyaçları şunlardır:

- Gözle görülür düşüş çıkış gücü ve kesim verimliliği.

- Tutarlılığı sürdürmede zorluk lazer ışını Kaliteli.

- Görünür hasar veya çatlaklar cam tüp.

- Uygun soğutmaya rağmen sık sık aşırı ısınma.

Değiştirme lazer tüpü doğru zamanda yapılması, diğer parçaların hasar görmesini önleyebilir. lazer kesim makinesi ve ürününüzde sürekli hassasiyet ve kalite sağlamak lazer kesim iş.

Sonuç: Verimli Lazer Kesim için CO2 Lazer Tüp Ömrünü En Üst Düzeye Çıkarın

Anlamak CO2 lazer tüpü kullanım ömrü ve bunu etkileyen faktörler, bir işletme işleten herkes için çok önemlidir. lazer kesim makinesi. Dikkat ederek lazer gücü, sıcaklık aralığı, soğutma si̇stemleri̇, ve düzenli bakım ile ömrünü önemli ölçüde uzatabilirsiniz. hizmet ömrü senin lazer tüpü ve genel olarak korumak performans senin lazer makinesi. Aşağıdakiler gibi kaliteli bileşenlere yatırım yapmak Reci tüpleri, ve aşağıdaki profesyonel tavsi̇ye maliyetli değişimleri ve arıza sürelerini en aza indirirken en iyi sonuçları elde etmenize yardımcı olacaktır. Doğru bakım ve dikkatli çalışma, aşağıdakileri sağlar lazer kesici saatlerce kullanım boyunca verimli ve hassas kalır. CO2 lazer tüpünüzün bakımı, makinenizin malzemeleri verimli ve etkili bir şekilde kesmeye devam etmesini de sağlar.