2025'te bir lazer kesici tüp seçerken, bazı önemli şeylere bakmanız gerekir.

- Şunları düşünün tüp tipi ve boyutu malzemeleriniz için.

- Daha iyi çalışmanıza yardımcı olmak için ne kadar iyi ve hızlı kestiğine bakın.

- Satın almadan önce makinenizin içine uyan uzunluğu ve çapı kontrol edin.

- Lazer gücü, stabilite ve kontrol sistemi özelliklerini karşılaştırın, böylece ihtiyacınız olana uyarlar.

- Makinenizin boyutunun ve CO2 uyumluluğunun doğru olduğundan emin olun, böylece kurulumda sorun yaşamazsınız.

Önemli Çıkarımlar

- Malzemeleriniz için doğru boru tipini ve boyutunu seçin. Bu, makinenizin daha iyi çalışmasına ve iyi sonuçlar vermesine yardımcı olur. Bir tüp satın almadan önce makinenizin alanını ölçün. Sorunları ve hasarı önlemek için tüp iyi oturmalıdır. Lazer gücünü eşleştirin Kesmek istediğiniz şeye göre. Daha fazla watt, kalın malzemeleri daha hızlı keser ve zaman kazandırır. Tüpünüze iyi bakın ve iyi bir soğutma sistemi kullanın. Bu, tüpünüzün çalışmasını sağlar ve daha uzun ömürlü olmasını sağlar. Tüpünüzü sık sık temizleyin. Uyumluluk için her zaman üreticinin talimatlarına bakın. Bu, sorunlardan kaçınmanıza yardımcı olur ve tüpünüzün doğru çalıştığından emin olmanızı sağlar.

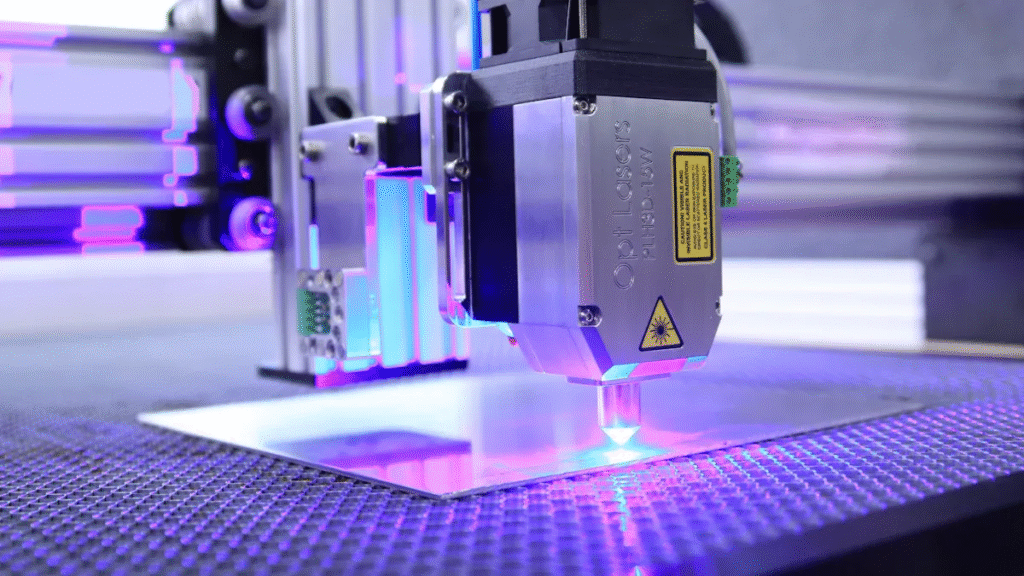

Lazer Kesici Tüp Seçimi

Güç ve Malzeme

Seçmek sağ lazer kesici tüp gücünü malzemelerinizle eşleştirmek anlamına gelir. Ne kadar kalınlıkta ve ne tür bir malzeme kullanacağınızı düşünmeniz gerekir. Aşağıdaki tabloda farklı malzemeler için en iyi gücün ne olduğu gösterilmektedir:

| Malzeme | Önerilen Güç Aralığı |

|---|---|

| Akrilik | 30 mm'ye kadar |

| Ahşap | 25 mm'ye kadar |

| Metal | 1,5 mm SS ve 2,5 mm CS'ye kadar |

Malzemeniz için yeterli watt gücüne sahip bir tüp seçin. Akriliği çok kullanıyorsanız, daha güçlü bir tüp kalın levhaları kesmeye yardımcı olur. Metal için, paslanmaz çelik veya karbon çelik kalınlığını kaldırabilecek bir tüp seçin.

İpucu: Daha fazla güce sahip lazerler, özellikle düz sacları daha hızlı keser. Tüp lazer kesimi, malzemeye zarar vermemek için dikkatli bir güç kontrolü gerektirir. Zor şekillere veya kaynaklara sahip tüpler, kaliteyi iyi tutmak için daha düşük hızlara ihtiyaç duyar.

- Malzeme düzgünse güçlü borular daha hızlı keser.

- Hasarı önlemek için tüplerin gücünü değiştirmelisiniz.

- Sert şekiller daha iyi sonuçlar için yavaş hızlara ihtiyaç duyar.

- Sac metal kesimi, daha az değişiklik gerektirdiği için boru kesiminden daha hızlıdır.

Tüp Uzunluğu ve Çapı

Bir lazer kesici tüpü satın almadan önce, makinenizin içindeki alanı ölçün. Tüpün doğru oturması için hem uzunluğu hem de çapı kontrol edin. Tüpün boyutu ne kadar iyi çalıştığını ve makinenizin performansını etkiler.

- Tüp çapı akış hızlarını ve sürtünmeyi değiştirirBu da nasıl çalıştığıyla ilgilidir.

- Boru uzunluğu sisteminizin ne kadar enerjiye ihtiyaç duyduğunu etkiler, bu nedenle makinenize uygun hale getirin.

- Daha uzun borular daha fazla basınca ihtiyaç duyabilir çünkü uzunluk arttıkça sürtünme de artar.

- Daha küçük tüpler daha yüksek basınç yapar, ancak daha büyük tüpler basıncı düşürür, bu da ne kadar iyi çalıştığını değiştirir.

Not: Yeni bir boru satın almadan önce daima makinenizin alanını ölçün. Tüp çok uzun veya genişse, sığmayacaktır. Makinenizi değiştirmeniz veya farklı bir tüp seçmeniz gerekebilir.

Çıktı Kararlılığı

Kararlı çıktı, her seferinde iyi kesim ve kazıma yapmanıza yardımcı olur. Bir CO2 lazer tüpünün ne kadar sabit çalıştığını birçok şey etkiler. Aşağıdaki tabloda ana şeyler ve ne yaptıkları listelenmiştir:

| Faktör | Açıklama |

|---|---|

| İşletim Gücü | Yüksek güç ekstra ısı üretir ve bu da tüpün ömrünü kısaltabilir. |

| Kesme Hızı | Yüksek hızlar daha fazla ısı üretir ve çıkış stabilitesine zarar verebilir. |

| Sıcaklık Aralığı | Doğru sıcaklığı korumak aşırı ısınmayı önler ve işleri sabit tutar. |

| Soğutma Sistemi Verimliliği | İyi soğutma ısıyı uzaklaştırır ve tüpün iyi çalışmasına yardımcı olur. |

| Gaz Kalitesi | Temiz gaz, çıktının yüksek ve sabit kalmasına yardımcı olur. |

| Çevresel Koşullar | Nem ve toz parçalara zarar verebilir ve işleri daha az stabil hale getirebilir. |

| Düzenli Bakım | Sık sık kontrol etmek ve temizlemek tüpün daha uzun süre dayanmasına yardımcı olur ve çıkışı sabit tutar. |

Puri Laser gibi bazı şirketler, CO2 lazer tüplerinin iyi kesim yaptığını ve daha uzun ömürlü olduğunu söylüyor. Müşteriler kumaş keserken sarı kenarlar olmaması gibi sabit çıktılar görürler. Güvenilir sonuçlar için iyi ışın kalitesine, doğru hizalamaya ve sabit güce sahip tüpler arayın.

Profesyonel İpucu: Tüpünüzü sık sık temizlemek ve iyi bir soğutma sistemine sahip olmak, çıktıyı sabit tutmaya yardımcı olur ve lazer kesici tüpünüzün daha uzun ömürlü olmasını sağlar.

CO2 Lazer Tüpü Uyumluluğu

Makineye Uygun

CO2 lazer tüpünün makinenize uyduğundan emin olmanız gerekir. İlk olarak, makinenizin içindeki alanı ölçün. Hem uzunluğu hem de çapı kontrol edin. Boru çok büyükse, sığmayacaktır. Bazı makineler daha uzun borular için uzatma eklemenize izin verir. Çoğu insan değişiklik yapmadan uyan tüpleri sever çünkü daha kolaydır.

| Boyut Tipi | Açıklama |

|---|---|

| Uzunluk | Kullanabileceğiniz en uzun boruyu bulmak için gravür makinenizin içini ölçün. |

| Çap | Borunun çapının makinenize uygun olduğundan emin olun. |

| Montaj | Bazı makineler daha uzun borular için uzatma eklemenize izin verir. |

Yeni bir tüp takmak için aşağıdaki adımları uygulayın:

- Kutuyu açın ve tüpte hasar olup olmadığına bakın.

- Makinenizi kapatın ve tüp bölmesini açın.

- Cıvataları boru tutucularından çıkarın.

- Tüpü, katodu aynaya bakacak şekilde koltuklara yerleştirin.

- Tüpü tutucularla birlikte sıkın.

İpucu: Bir tüp satın almadan önce daima ölçülerinizi ve montaj tarzınızı kontrol edin. Bu, hatalardan kaçınmanıza yardımcı olur ve kurulumu kolaylaştırır.

Elektrik Bağlantıları

Tüpün makinenizin elektriği ile çalıştığından emin olmak önemlidir. Her CO2 lazer tüpü belirli bir voltaj ve akıma ihtiyaç duyar. Kabloları kılavuzunuzdaki voltaj ve akımla eşleştirin. Yüksek voltaj kablosunu tüpün anoduna bağlayın. Katodu çıkış ucuna takın. Hiçbir şeyin zarar görmemesi için tüm kabloların sıkı olduğundan emin olun.

- Farklı CO2 tüpleri farklı elektrik kurulumlarına ihtiyaç duyar. Daha büyük tüpler daha fazla voltaja ihtiyaç duyar.

- Örneğin, bir 40W tüp 14.000 ila 20.000 volt DC kullanır ve 15-20mA.

- CO2 lazerler normal ev voltajlarını kullanmazlar. Özel yüksek voltaj kablolarına ve ekstra güvenlik adımlarına ihtiyaç duyarlar.

Not: Yüksek voltajla çalışırken her zaman güvenlik kontrolleri yapın. İyi bağlantılar makinenizi güvende tutar ve sizi korur.

Üretici Özellikleri

Uyumluluğu kontrol etmek için her zaman üreticinin teknik özelliklerine bakın. Bu özellikler hangi tüplerin makinenizle çalıştığını gösterir. Size hangi güç kaynağına ve montaj stiline ihtiyacınız olduğunu söylerler. Üreticiler ayrıca doğru konektörleri ve voltajı da listeler.

| Şartname | Açıklama |

|---|---|

| Güç kaynağı gerilimi | örneğin, 110V vs. 220V |

| Konnektör tipleri | örneğin, Yüksek Gerilim (HV) vs. RF |

| Montaj stili | örneğin, yatay vs. dikey |

Tüpünüzün aşağıdakilerle eşleştiğinden emin olun GÜÇ KAYNAĞI, lensler ve kullandığınız malzemeler. Tüpünüze uyan iyi bir güç kaynağı sisteminizin iyi çalışmasını sağlar ve tüpün daha uzun ömürlü olmasına yardımcı olur. Yanlış güç kaynağı kullanmak tüpünüze zarar verebilir ve daha kötü çalışmasına neden olabilir.

- Üretici ipuçları iyi tüpler seçmenize yardımcı olur.

- Işın kalitesine, tüpün ne kadar dayandığına ve güç kullanımına önem verirler.

- Bu ipuçlarını takip etmek size daha iyi sonuçlar verir ve tüpünüzün uzun süre çalışmasını sağlar.

Profesyonel İpucu: Bir tüp seçerken ve takarken her zaman üreticinin tavsiyelerine uyun. Bu, tüpünüzün lazer kesicinize uyduğundan ve iyi çalıştığından emin olmanızı sağlar.

CO2 Soğutma ve Entegrasyon

Soğutma Tipleri

Güvenli ve istikrarlı bir çalışma için lazer kesici tüpünüzü soğuk tutmanız gerekir. Aralarından seçim yapabileceğiniz çeşitli soğutma sistemleri vardır. Her sistem farklı şekilde çalışır ve farklı ihtiyaçlara uyar. Aşağıdaki tablo ana türleri ve nasıl karşılaştırıldıklarını göstermektedir:

| Soğutma Sistemi | Açıklama | Verimlilik Karşılaştırması |

|---|---|---|

| Hava Soğutma | Isıyı uzaklaştırmak için hava kullanır. Daha az maliyetlidir ve çok az bakım gerektirir. | Daha az verimli. Yüksek güçlü makineler için iyi değildir. Gürültülü ve tozlu olabilir. |

| Chiller Soğutma | Suyu tüpten akmadan önce soğutmak için ayrı bir ünite kullanır. | Çok verimlidir. Hassas sıcaklık kontrolü sağlar. Daha pahalı ve bakım gerektiriyor. |

| Termoelektrik Soğutma | Sıcaklık kontrolü için bir Peltier soğutucu kullanır. | Hassas kontrol. Yüksek güç için yeterince güçlü değil. Daha pahalı. |

Su soğutma, yüksek güçlü CO2 tüpleri için en iyi sonucu verir. Isıyı iyi idare eder ve sıcaklığı sabit tutar. Hava soğutma basit ve kurulumu kolaydır, ancak güçlü lazerleri soğutamaz.

Sistem Boyutlandırma

Soğutma sisteminizi lazer kesici tüpünüze uyacak şekilde boyutlandırmalısınız. Lazer gücünü ve ne kadar ısı ürettiğini kontrol ederek başlayın. Bu ısıyla başa çıkabilecek bir soğutma sistemi seçin. Çoğu uzman şunları yapmanız gerektiğini söylüyor yüzde 10 ila 20 arasında bir güvenlik marjı ekleyin soğutma kapasitenize bağlıdır. Yüksek güçlü tüpler için su sıcaklığını 18°C (64°F) ile 20°C (68°F) arasında. Suyun dakikada yaklaşık 1 litre aktığından emin olun. Tüpün maksimum gücünün en az beş katı soğutma kapasitesine sahip bir soğutucu seçin. Popüler soğutucular arasında CW-5000 ve CW-5200 bulunur. Tüpünüzü korumak için her zaman sıcaklık ve su akışı için kilitler kullanın.

İpucu: Tüpünüzün ihtiyaçlarına uygun bir soğutma sistemi, istikrarlı performans ve daha uzun tüp ömrü elde etmenize yardımcı olur.

Entegrasyon İpuçları

Soğutma sisteminizin daha iyi çalışmasını şu şekilde sağlayabilirsiniz bazı basit adımları izleyerek:

- Tüm hatlarda ve bağlantılarda sızıntı veya tıkanıklık olup olmadığını kontrol edin.

- Değişiklikleri izlemek için sıcaklık sensörleri takın.

- Tozun hava akışını engellemesini önlemek için radyatörü temiz tutun.

- Mineral birikimini önlemek için damıtılmış veya deiyonize su kullanın.

- Aşırı ısınmayı önlemek için su seviyelerini sık sık izleyin.

- En iyi sonuçlar için soğutucunuzu düzenli olarak temizleyin.

- Tüp sıcaklığını koruyun 18°C ile 25°C (64°F ile 77°F) arasında.

Bu ipuçlarını takip ederseniz, CO2 lazerinizin iyi çalışmasına ve daha uzun süre dayanmasına yardımcı olursunuz. İyi soğutma ve dikkatli kullanım tüpünüzün ömrünü yüzde 50'ye kadar uzatır. Lazerinizi uzun süre tam güçte çalıştırmaktan kaçının. Bu, tüpün ömrünü yüzde 20 ila 30 oranında kısaltabilir.

Tüp Kalitesi ve Kullanım Ömrü

Yapı Kalitesi

Bir CO2 lazer tüpü seçerken, ne kadar iyi yapıldığına bakın. İyi tüpler, içinde özel gaz bulunan sızdırmaz cam hazneler kullanır. Gaz çoğunlukla karbondioksit. Elektrik hazneden geçer ve güçlü bir lazer ışını oluşturur. Bu tüpleri birçok şeyi kesmek veya kazımak için kullanabilirsiniz. Plastik, ahşap, deri, akrilik, kağıt ve kumaş üzerinde çalışırlar. Özel kelepçeler boruyu bükülmemesi için yerinde tutar. Destek silindirleri boruyu düz tutmaya ve gerilimi azaltmaya yardımcı olur. Boru kesim sırasında malzemeye temas etmez. Bu, malzemenin şekil dışı bükülmesini önler. Akıllı kesim yolları ve ısı kontrolü sıcaklığı sabit tutar. Bu da bükülmeyi önlemeye yardımcı olur. CNC otomasyonu hataları önlemeye yardımcı olur ve kesimleri kesin tutar. Boru iyi üretilirse daha uzun ömürlü olur ve daha iyi çalışır.

Garanti

Bir tüp satın almadan önce daima garantisine bakın. En iyi markalar farklı garanti süreleri verir. Aşağıdaki tabloda bazı markaların sundukları gösterilmektedir:

| Marka | Garanti Süresi | Ek Şartlar |

|---|---|---|

| Paralaks Teknolojisi | 1 yıl | 4 yıl çıkış gücü garantisi |

| BST Lazer | 2 yıl | Ömür boyu ücretsiz hizmet |

A iyi garanti satın alma konusunda kendinizi güvende hissetmenize yardımcı olur. Uzun garantili bir tüp alırsanız, bir şeyler ters giderse daha fazla yardım alırsınız. Bu, şirketin ürününün uzun ömürlü olacağına ve iyi çalışacağına güvendiği anlamına gelir.

Işın Hassasiyeti

Kiriş hassasiyeti her iş için önemlidir. Tüpünüzün uzun süre temiz ve kesin kesimler yapmasını istersiniz. Tüpü kullandığınız yer çok önemlidir. Sıcaklığı, nemi ve havayı temiz tutun en iyi sonuçlar için. Tüpün daha uzun süre dayanmasına yardımcı olmak için güçlü malzemeler ve akıllı makineler kullanın. Çok ısınmasını önlemek için tüpünüzü sık sık temizleyin ve kontrol edin. Bu, ışının keskin kalmasını sağlar. İyi bir soğutma sistemi de tüpün daha uzun süre dayanmasına yardımcı olur. Kalite kontrolleri ve düzenli bakım, tüpünüzün hassas kalmasına ve yıllarca çalışmasına yardımcı olur. En iyi markaların iyi tüplerinin çoğu 1.000 ila 10.000 saat. Tüpünüze iyi bakarsanız üç ila beş yıl dayanabilir. A sınıfı tüpler genellikle iki veya üç yıl, hatta daha uzun süre iyi çalışır.

İpucu: Çalışma alanınızı temizler ve tüpünüze sık sık bakım yaparsanız, lazer tüpünüzün daha uzun süre dayanmasına ve daha iyi çalışmasına yardımcı olursunuz.

Bunları yaparak doğru lazer kesici tüpünü seçebilirsiniz: İlk olarak, makinenizin alanını ölçün. Tüpün boyutunu ve özelliklerini ihtiyacınız olan şeylerle eşleştirin. İşletmenizin ne yaptığını düşünün. Hangi malzemeleri kullandığınızı ve ne kadar ürettiğinizi bilin. Şu özelliklere sahip makineleri kullanın güçlü destek sistemleri. Yüzer kuyruk destekleri ağır borularda yardımcı olur. Ayarlayabileceğiniz fikstürler arayın. Gelişmiş yazılım daha hassas kesim yapmanıza yardımcı olur.

| Anahtar Faktör | Açıklama |

|---|---|

| Boyut ve Çap | Makinenizden emin olun ihtiyacınız olan tüpe uyar lazer işiniz için. |

| Satış Sonrası Hizmet | Güvenilir destek, makinenizin sorunsuz çalışmasını sağlar. |

İpucu: Satın almadan önce üreticiden yardım isteyin ve uzman tavsiyesi alın. Bu, paraya mal olan hatalardan kaçınmanıza yardımcı olur. Ayrıca makinenizin iyi çalıştığından emin olmanızı sağlar.

SSS

Bir lazer kesici tüp satın almadan önce kontrol edilmesi gereken en önemli özellikler nelerdir?

Tüpün watt gücüne ve soğutma ihtiyaçlarına bakın. Kesim sisteminizle çalıştığından emin olun. Her zaman üreticinin özelliklerini makinenizle eşleştirin. Bu, kurulum sırasında sorunlardan kaçınmanıza yardımcı olur. Ayrıca tüpünüzün iyi çalıştığından emin olmanızı sağlar.

Makinem için maksimum boru çapını nasıl ölçebilirim?

Makinenizin içinde tüp için yer bulun. Sığan en büyük boru çapını kontrol etmek için bir mezura kullanın. Diğer parçalara temas etmediğinden emin olun. En iyi tüp boyutu için kılavuza bakın. Bu, hasarı önlemeye yardımcı olur.

Lazer kesici tüpleri için maksimum tüp uzunluğu neden önemlidir?

Tüpün uzunluğu gücü ve dengeyi etkiler. Tüp çok uzunsa sığmayacaktır. Her zaman sahip olduğunuz alanı ölçün. Doğru uzunluk için üreticiye danışın.

Yeni bir lazer kesici tüpe yatırım yapmadan önce test edebilir miyim?

Birçok tedarikçi bir demo veya örnek kesim denemenize izin verir. Bu, tüpün malzemelerinizle nasıl çalıştığını gösterir. Önce test etmek hatalardan kaçınmanıza yardımcı olur. Tüpün istediğiniz şeyi yaptığından emin olmanızı sağlar.

Kesim sistemimin yeni bir CO2 tüpünü destekleyip desteklemediğini nasıl bilebilirim?

Çalışan tüp modelleri için makinenizin kılavuzunu okuyun. Elektrik ve montaj ihtiyaçlarını kontrol edin. Sisteminiz tüpün boyutuna ve bağlantılarına uygunsa, tüpü takabilirsiniz. Emin değilseniz teknik destekten yardım isteyin.