Lazer kesiciniz güç kaybettiğinde veya beklenmedik bir şekilde davrandığında, CO2 lazer tüpü değişimini düşünmeniz gerekebilir. Ani sorunları önlemek için düzenli bakım şarttır. Çoğu CO2 lazer tüpünün ömrü şu kadardır 2.000 ila 10.000 saatkalitelerine ve kullanımlarına bağlı olarak. Durumunuzu değerlendirmek için bu kontrol listesini kullanın:

- Tüpünüz olması gerektiği kadar uzun süre dayandı mı?

- Bu kadar etkili kesmediğini fark ettiniz mi?

- Görünür çatlaklar veya sızıntılar var mı?

- Makine çalışmıyor mu veya zayıf bir ışın üretiyor mu?

Bu faktörleri değerlendirmek, CO2 lazer tüpü değişiminin gerekli olup olmadığını belirlemenize yardımcı olacaktır.

Önemli Çıkarımlar

- CO2 lazer tüpünüzü kontrol edin zayıf kesim veya görebileceğiniz hasar gibi sorunlar için sık sık kontrol edin. Bu, ne zaman değiştirmeniz gerektiğini bilmenize yardımcı olur.

- Başlamadan önce çalışma alanınızı hazırlayın ve ihtiyacınız olan tüm aletleri toplayın. Güvenlik çok önemlidir, bu nedenle makineyi her zaman kapatın ve fişini çekin.

- Eski tüpü çıkarmak ve yenisini takmak için basit adımları kullanın. En iyi sonuç için aynaların doğru hizalandığından emin olun.

- CO2 lazer tüpünüzün bakımını yapın Aynaları temizleyerek ve sık sık sızıntı olup olmadığına bakarak. Bu, tüpünüzün daha uzun süre dayanmasına yardımcı olur.

- Zor sorunlarda veya tüpü nasıl değiştireceğinizi bilmiyorsanız uzmanlardan yardım isteyin. Onların yardımı daha fazla hasarı önleyebilir ve sizi güvende tutabilir.

Değiştirmek mi, Onarmak mı?

Dikkat Edilmesi Gereken İşaretler

CO2 lazer tüpünüzün değiştirilmesi gerekebileceğini gösteren bazı işaretler vardır. Bu işaretleri izlemek, sorunları daha da kötüleşmeden önce durdurmanıza yardımcı olur. Bu şekilde makineniz iyi çalışmaya devam eder.

- Güç düşüşü: Makine o kadar güçlü çalışmıyor. Daha az iş bitirirsiniz.

- Kararsız lazer çıkışı: Işın yanıp sönüyor veya gücü değişiyor. Bu, içeride bir sorun olduğu veya gaz kaçağı olduğu anlamına gelebilir.

- Sık arızalar: Makine çok sık duruyor. Tamir etmek işe yaramıyor.

- Gaz kaçağı: Güç düşer ve diğer parçalar zarar görebilir.

- Tüp duvarında kirlenme veya hasar: Işın zayıflıyor veya sabit kalmıyor.

- Nominal hizmet ömrüne ulaşıyor: Boru neredeyse tükenmiştir. Şimdi değiştirilmesi ani sorunları önler.

- Anormal çalışma sıcaklığı: Tüp çok sıcak hissediyor. Bunu görmezden gelirseniz kırılabilir.

İpucu: Bu işaretlerden birden fazlasını fark ederseniz, şunları düşünmelisiniz yeni bir CO2 lazer tüpü almak Yakında.

Hızlı Karar Kontrol Listesi

CO2 lazer tüpünüzü onarmanız mı yoksa değiştirmeniz mi gerektiğine karar vermenize yardımcı olması için bu listeyi kullanın:

- Tüp olması gerektiği kadar uzun süre kullanıldı mı?

- Onarımlar tekrar düzgün çalışmasını sağlamaz mı?

- Hasar küçük mü ve çalışma şeklini değiştirmiyor mu?

- Tüpte gaz kaçağı veya kirli bir duvar var mı?

- Onarımlar daha pahalıya mı mal oluyor ya da çok mu gerçekleşiyor?

- Tüp, kesme ve oyma için ihtiyacınız olan şeye hala uyuyor mu?

Bunların çoğuna "evet" diyorsanız, muhtemelen yeni bir CO2 lazer tüpü almalısınız. Yalnızca küçük sorunlar varsa, bunları düzeltmek yeterli olabilir.

Dikkate Alınması Gereken Faktörler

Ne yapacağınıza karar vermeden önce birkaç şey düşünün. Bu şeyler size yardımcı olur en iyi yolu seçin makinenizi çalışır durumda tutmak için.

- Tüpün malzemesi ve tipi: Cam tüpler daha az maliyetlidir ve dikkatli işler için iyidir. Metal tüpler daha uzun ömürlüdür ve büyük işler için daha iyidir.

- Çıkış gücü: Tüp, makinenizin gücüne uygun olmalıdır. Bu daha iyi çalışmanıza yardımcı olur.

- Verimlilik: Tüpler farklı sürelerde dayanırÇok kısa sürede çalışmayı bırakmayacak bir tüp seçin.

- Uyumluluk: Tüpün makinenize uyduğundan emin olun.

- Kesme ve gravür gereksinimleri: Bazı işler için daha fazla güç veya daha iyi bir ışın gerekir.

- Soğutma sistemi: İyi bir soğutma sistemi tüpün daha uzun süre dayanmasına yardımcı olur.

- Maliyet ve marka itibarı: Fiyat önemlidir, ancak iyi markalar daha güvenilirdir.

- Çevresel etki: Gezegene yardımcı olacak şekilde üretilmiş tüpleri seçmeye çalışın.

Emin değilseniz, bir uzmandan yardım isteyebilirsiniz. Uzmanlar hasara bakabilir, onarım fiyatlarını kontrol edebilir ve size en iyisinin ne olduğunu söyleyebilir. Düzenli kontroller yapmak ve makinenize özen göstermek daha uzun ömürlü olmasına yardımcı olur ve sürpriz sorunları önler.

CO2 Lazer Tüpü Değiştirme Adımları

Hazırlık ve Güvenlik

Başlamadan önce çalışma alanınızı hazırlayın. İhtiyacınız olan tüm aletleri toplayın. Güvenlik çok önemlidir. Makinenizi kapatın ve fişini çekin. Koruyucu gözlük ve eldiven takın. Bu sizi cam ve elektrikten korur.

Bu alet ve malzemelere ihtiyacınız olacak:

- Temassız voltaj dedektörü

- 22 kutuplu gerilim ve süreklilik test cihazı

- Alyan anahtar seti

- Tornavida seti

- Anahtar seti

- Ayna çıkarma aleti

- Sıkma aleti ve terminal uçları

- Tel sıyırıcılar ve tel kesiciler

- 20 SWG (18AWG) tel

- Wago 221 seti veya takılabilir konnektör seti

- El işi bıçağı (silikon tüpü kesmek için)

- Havya ve lehim

- Beyaz lityum gres, pamuklu çubuklar, izo-alkol ve fırçalar

- Makine blokları ve çekiç

İpucu: Çalışma alanınızı temiz ve düzenli tutun. Bu, kazaları önlemenize yardımcı olur ve işleri kolaylaştırır.

Eski Tüpün Çıkarılması

Arka taraftaki lazer tüp bölmesini açın. Tüp klipslerini gevşetmek için bir tornavida kullanın. Kabloları dikkatlice tüpten çıkarın. Silikon su hortumlarını bir maket bıçağı ile kesin. Bağlantı elemanlarını bir anahtar veya alyan anahtarı ile çıkarın. Eski boruyu yavaşça kaldırın. Tüpü sert bir şeye çarpmayın.

Kir veya artık madde görürseniz, izo-alkol ve pamuklu çubukla temizleyin. Koltuklarda ve hortumlarda hasar olup olmadığına bakın. Yeni tüpü takmadan önce aşınmış görünen parçaları değiştirin.

Yeni Tüpün Takılması

Yeni tüpü çıkarın ve çatlak olup olmadığını kontrol edin. Tüpü katodu aynaya bakacak şekilde yuvalarına yerleştirin. Tüpü klipslerle sabitleyin. Katot kablosunu ateşleme ünitesinin katot kablosuna bağlayın. Tutmak için koli bandı kullanın. Anot telini bir silikon hortum ile bağlayın. Ateşleme ünitesinin anot teli ile bükün. Bağlantıyı yüksek gerilim bandı ile sarın.

Su giriş hortumunu anot tarafına bağlayın. Çıkış hortumunu katot tarafına bağlayın. Silikon tüplerin sıkı olduğundan emin olun. Sızıntıları durdurmak için plastik bağlar kullanın. Reci tüpleri gibi bazı tüpler için kabloları doğru cıvatalara bağlayın. Tüpü, su çıkışı biraz yukarı bakacak şekilde ayarlayın.

Not: Yeni tüpün watt değerini ihtiyaçlarınıza göre ayarlayın. 60W'lık bir tüp ⅜" kalınlığa kadar kesim yapabilir. 80W veya 100W'lık bir tüp ½ inç veya daha fazlasını kesebilir. Daha düşük güçte daha güçlü bir tüp kullanmak daha uzun süre dayanmasına yardımcı olabilir.

| Tüp Watt Değeri | Maksimum Kalınlık Kesme Potansiyeli |

|---|---|

| 40W | ¼" |

| 60W | ⅜" |

| 80W-100W | ½" |

| 130W+ | ½" veya daha fazla |

Farklı malzemeler farklı güç seviyelerine ihtiyaç duyar. Akrilik, sert ahşaba göre daha kolay kesilir. En iyi sonuçlar için hızınızı ve gücünüzü değiştirin.

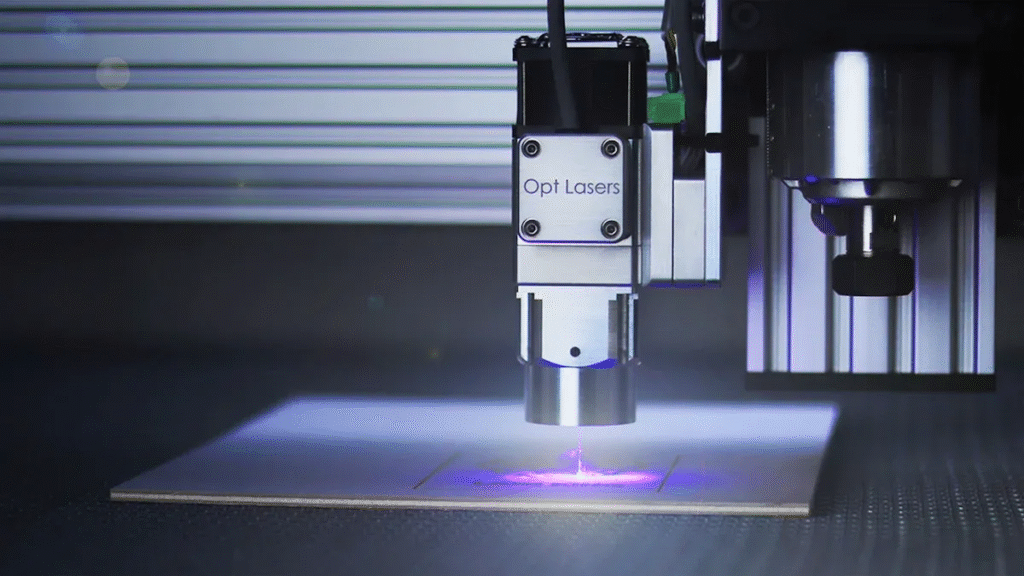

Hizalama ve Test

İyi hizalama tüpünüzün iyi çalışmasına yardımcı olur. İlk aynanın önündeki pencerenin üzerine maskeleme bandı koyun. Lazere darbe verin ve işarete bakın. Işın merkeze gelene kadar ilk aynayı hareket ettirin. Bunu ikinci ve üçüncü aynalar için de yapın. Her seferinde ışını ortalamak için vidaları kullanın.

Aynaları hizaladıktan sonra, lazeri mercekten geçirin. Lazer kafasının altına kontrplak koyun ve yanık noktasını kontrol edin. Nokta temiz ve ortada olmalıdır. Değilse, küçük değişiklikler yapın ve tekrar test edin.

Uyarı: Hizalama veya test ile ilgili sorun yaşıyorsanız, profesyonellerden yardım alın. Birçok şirket CO2 lazer tüpü değişimi ve kalibrasyonu, acil onarım, optik kalibrasyon ve ışın kalitesi kontrolleri sunar. Bu hizmetler makinenizin güvenli ve iyi çalışmasına yardımcı olur.

| Sunulan Hizmet | Açıklama |

|---|---|

| CO2 Lazer Tüpünün Değiştirilmesi ve Kalibrasyonu | CO2 lazer tüpleri için değiştirme ve kalibrasyon hizmetleri. |

| Acil Yerinde Onarım ve Uzaktan Destek | Lazer sorunları için yerinde veya uzaktan destek yoluyla anında yardım. |

| Lazer optik bileşen onarımı ve kalibrasyonu | Lazer sistemlerindeki optik bileşenlerin onarımı ve kalibrasyonu. |

| Lazer rezonatör lens temizliği ve kaplama onarımı | Lazer rezonatör lenslerinin temizlenmesi ve onarımı. |

| Lazer güç kaynağı ve devre arıza teşhisi | Lazer güç kaynakları ve devrelerindeki arızaların teşhisi ve onarımı. |

| Lazer soğutma sistemi bakımı ve sızıntı onarımı | Sızıntı onarımları da dahil olmak üzere lazerler için soğutma sistemlerinin bakım ve onarımı. |

| Lazer ışını kalitesi optimizasyonu ve kolimasyon onarımı | Lazer ışını kalitesini optimize etme ve kolimasyon onarımları gerçekleştirme hizmetleri. |

| Lazer kontrol sistemi yazılım ve donanım arıza onarımı | Lazer kontrol sistemi yazılım ve donanımındaki arızaların onarımı. |

| Lazer mekanik yapısı, gevşek veya hasarlı, onarın | Lazer sistemlerindeki gevşek veya hasarlı mekanik yapılar için onarım hizmetleri. |

İşiniz bittikten sonra birkaç deneme kesimi yapın. Sabit güç ve temiz kesimler olup olmadığına dikkat edin. Sorun görürseniz, bağlantılarınızı ve hizalamayı tekrar kontrol edin. Makinenizin bakımını yapmak daha uzun ömürlü olmasına ve daha iyi çalışmasına yardımcı olur.

Onarım Seçenekleri

Ortak Yöntemler

Makinenizi tamir ettirmeden önce tamir etmenin birkaç yolu vardır Tam CO22 lazer tüpü deği̇şti̇rme. En iyi yollardan bazıları şunlardır:

- Lazer Tüpünün Değiştirilmesi: Zayıf kesim veya hasar görüyorsanız bu en iyi seçimdir.

- Hizalama: Lazer ışınının doğru yere çarpması için aynaları ve tüpü hareket ettirin. İyi hizalama makinenizin daha iyi çalışmasına yardımcı olur.

- Bakım Prosedürleri: Aynaları temizleyin ve soğutma sistemini sık sık kontrol edin. Bunu yapmak tüpünüzün daha uzun süre dayanmasına yardımcı olur.

Güç kaynağına da bakmalısınız. Bazen kötü bir güç kaynağı tüpün bozukmuş gibi görünmesine neden olabilir. Ne yapacağınızdan emin değilseniz, bir uzmandan makinenizi kontrol etmesini isteyin.

Onarım Mantıklı Olduğunda

Düzeltme CO2 lazer tüpü sorun küçük olduğunda iyi bir fikirdir. Kirli aynalar veya tıkanmış bir soğutma sisteminin onarılması kolaydır. Bu onarımlar fazla maliyetli değildir ve makinenizin iyi çalışmasına yardımcı olur. Sorun tüpün içindeyse, gaz kaybı veya kırık elektrotlar gibi, onarımlar daha maliyetli ve daha risklidir. Bu durumlarda, özellikle makinenizi çok kullanıyorsanız tüpü değiştirmeniz daha iyi olacaktır.

İpucu: Tüpünüz çok eski değilse ve sadece küçük sorunları varsa, tamir etmek paradan tasarruf etmenizi sağlayabilir. Büyük hasar varsa veya makine sık sık bozuluyorsa, yeni bir tüp almak sizin için daha iyidir.

Riskler ve Sınırlar

Düzeltme CO2 lazer tüpü bazı riskleri ve sınırları vardır:

- Zorlu onarımlar özel aletler ve beceriler gerektirir.

- Onarımdan sonra hizalama veya kalibrasyon ile ilgili sorun yaşayabilirsiniz.

- Çoğu şirket tüpü kendiniz tamir etmenizi istemez.

- Eğitim almadan tüpü onarmaya çalışmak işleri daha da kötüleştirebilir.

- Yüksek voltajlı parçalara yanlış şekilde dokunursanız tehlikeli olur.

Zorlu onarımlar için bir profesyonelden yardım istemelisiniz. Bu sizi güvende tutar ve makinenize daha fazla zarar gelmesini önler.

Sorun Giderme ve Bakım

Ortak Sorunlar

Bazen lazer kesiciniz doğru çalışmaz. Bazı sorunlar diğerlerinden daha fazla olur. Bu sorunları arayın:

- Düzensiz kesimler veya atlanan adımlar kayış çok gevşekse veya Y ekseni mili hizalanmamışsa meydana gelebilir.

- Mekanik sıkışma makinenin hareket etmesini durdurabilir.

- Zayıf veya dengesiz lazer çıkışı, hizalamada veya güç kaynağında bir sorun olduğu anlamına gelebilir.

- Cam borudaki çatlaklar veya su sızıntıları makinenin aniden arızalanmasına neden olabilir.

⚠️ UYARI: Makineyi daima kapatın ve fişini çekin içindeki herhangi bir parçaya dokunmadan önce. Camda çatlak olup olmadığını kontrol edin. Dış çekirdeğe su sızmadığından emin olun. Kablolarda yanık veya erimiş noktalar olup olmadığına bakın.

CO2 lazer sisteminizi onarmak için aşağıdaki adımları uygulayın:

- Güç kaynağını kontrol edin. Bağlı olduğundan ve çalıştığından emin olun.

- Lazer sistemi kontrolörüne bakın. Çalışıp çalışmadığını ve doğru bağlanıp bağlanmadığını görün.

- Lazer tüpünü kontrol edin. Hizalandığından ve sıkı tutulduğundan emin olun.

Bunları kontrol ettikten sonra hala sorun görüyorsanız, CO2 lazer tüpünü değiştirmeniz gerekebilir.

Önleyici Bakım

Lazer tüpünüzün bakımını yaparak daha uzun süre dayanmasına yardımcı olabilirsiniz. Önemli parçaları temizlemek, kontrol etmek ve değiştirmek için bir plan yapın. Lazer tüpünü sık sık temizleyin. Toz veya kir olup olmadığına bakın. Tüpte hasar veya garip işaretler olup olmadığını kontrol edin ve bunları hızla düzeltin.

İşte makinenizin iyi çalışmasını sağlamak için bazı ipuçları:

- Her zaman tam güç kullanmayın. Her iş için gücü değiştirin.

- Hava desteğinin dumanı ve kiri üflemek için çalıştığından emin olun.

- Odayı 68°F ile 90°F arasında tutun. Nemi 35% ile 80% arasında tutun.

- Makineyi çok fazla açıp kapatmayın. Bu, hızlı sıcaklık değişimlerini durdurur.

- Cam boruyu yumuşak bir bez ve doğru temizleyici ile temizleyin.

- Soğutma sistemine dikkat edin. Temiz su kullanın ve pompa ile soğutucuyu kontrol edin.

Birçok şey tüpün uzun süre dayanmamasına neden olabilir. Yüksek güç, hızlı kesim ve kötü hava daha hızlı aşınmasına neden olabilir. Toz, yüksek nem ve çok sıcak veya soğuk odalar ayrıca daha az iyi çalışmasını sağlar.

| Üretici/Tür | Ortalama Ömür (saat) |

|---|---|

| Genel CO2 lazer tüpleri | 1,000 – 10,000 |

| SPT tüpler (80W altı) | 3.000'e kadar |

| Çin markalı olmayan cam tüpler | 1,000 – 1,500 |

| Chengdu cam tüpler | 1,500 – 3,000 |

| RECI tüpleri | 10.000'e kadar |

| Ortalama yaşam süresi | 5,000 – 7,000 |

Makinenizi temizlemek, kontrol etmek ve doğru şekilde kullanmak pahalı onarımlardan kaçınmanıza yardımcı olur. Ayrıca lazer kesicinizin iyi çalışmasını sağlar.

Aşağıdaki adımları izleyerek sorunsuz CO22 lazer tüpü değişimi gerçekleştirebilirsiniz anahtar adımlar:

- Aletlerinizi hazırlayın ve tüp uyumluluğunu kontrol edin.

- Eski boruyu çıkarın ve yenisini dikkatle takın.

- Aynaları hizalayın ve sistemi sızıntı ve ışın kalitesi açısından test edin.

- Aynaları temizleyin ve sızıntı olup olmadığını inceleyin Erken başarısızlığı önlemek için düzenli olarak.

Güvende kalın, makinenizin bakımını yapın ve karmaşık sorunlarla karşılaşırsanız profesyonellere ulaşın. Lazerinizin sorunsuz çalışmasını sağlamak için kontrol listesini ve sorun giderme ipuçlarını kullanın.

SSS

CO2 lazer tüpünü ne sıklıkla değiştirmelisiniz?

Çoğu CO2 lazer tüpü 2.000 ila 10.000 saat çalışır. Tüpünüzün ne kadar iyi çalıştığını birkaç ayda bir kontrol edin. Zayıf kesiyorsa, ışın sabit değilse veya hasar görüyorsanız tüpü değiştirin.

Çatlamış bir CO2 lazer tüpünü onarabilir misiniz?

Çatlak bir tüpü güvenli bir şekilde tamir edemezsiniz. Çatlaklar sızıntı yapar ve tüpün kötü çalışmasına neden olur. Tüpü hemen değiştirin daha fazla hasarı durdurmak ve güvende kalmak için.

Kalın malzemeleri kesmek için hangi watt CO2 lazer tüpüne ihtiyacınız var?

Tüpünüzü malzemenin kalınlığına göre seçin. Size yardımcı olması için bu tabloyu kullanın:

| Malzeme Kalınlığı | Önerilen Watt |

|---|---|

| 1/4″'e kadar | 40W |

| 3/8″'e kadar | 60W |

| 1/2″'ye kadar | 80W-100W |

Lazer kesiciniz neden aniden güç kaybediyor?

Tüp eskiyse, güç kaynağı bozuksa veya soğutma sistemi çalışmıyorsa makineniz güç kaybedebilir. Her parçayı kontrol edin ve çalışmayan her şeyi değiştirin.

Tüp değişimi için profesyonel yardıma mı ihtiyacınız var?

Güvenlik, hizalama veya kalibrasyon konusunda emin değilseniz bir uzmandan yardım alın. Profesyoneller tüpü takabilir ve test edebilir. Bu, makinenizin güvende olmasını ve iyi çalışmasını sağlar.