Se você está procurando o melhor tubo de corte a laser em 2025, este guia é para você. Explicaremos o que são tubos para cortadores a laser, como eles funcionam e apresentaremos os principais modelos a serem considerados. Descubra qual tubo melhorará sua precisão e eficiência de corte.

Principais conclusões

- Os tubos de corte a laser são essenciais para o corte de precisão em vários setores, sendo que os modelos de 2025 utilizam tecnologia avançada de laser de fibra para aumentar a velocidade e a eficiência.

- Os principais benefícios do corte de tubos a laser incluem precisão micrométrica, eliminação de operações secundárias e versatilidade no manuseio de diferentes materiais, o que os torna ideais para projetos complexos.

- Ao selecionar um tubo para cortador a laser, os fatores importantes incluem o tipo de tubo, a compatibilidade do material, a potência do laser e os recursos que favorecem a produtividade e a eficiência.

Introdução à tecnologia a laser

A tecnologia a laser transformou o cenário da fabricação moderna, especialmente no campo do corte de tubos a laser. Ao aproveitar o poder da luz focalizada, as máquinas de corte de tubos a laser podem cortar tubos e perfis com precisão e velocidade inigualáveis. Essa tecnologia avançada permite que os fabricantes produzam cortes de alta qualidade em uma ampla gama de materiais e perfis de tubos, de projetos simples a altamente complexos.

A adoção do corte de tubos a laser levou a melhorias significativas na qualidade e na eficiência do processamento. As empresas agora podem produzir padrões complexos de corte de tubos com desperdício reduzido e tempo de processamento minimizado, o que lhes dá uma vantagem distinta no mercado competitivo atual. A versatilidade da tecnologia de corte de tubos a laser significa que ela é amplamente utilizada em setores como engenharia mecânica, construção de sistemas e fabricação de móveis, onde a demanda por precisão e qualidade é fundamental.

À medida que a tecnologia a laser continua a evoluir, seu papel no corte de tubos só se expandirá, permitindo que os fabricantes ultrapassem os limites do que é possível na produção de tubos e perfis.

Entendendo os tubos do cortador a laser

Os tubos de corte a laser são o coração pulsante das modernas máquinas de corte a laser, fornecendo a energia necessária para cortar vários materiais com precisão. Esses tubos são capazes de produzir ângulos precisos e bordas chanfradas, permitindo cortes detalhados e precisos. Independentemente de estar trabalhando com tubos redondos, quadrados ou retangulares, o corte de tubos a laser garante cortes limpos que atendem às especificações exatas, o que é fundamental para resultados de alta qualidade. Tubos de laser de CO2, O modelo de potência de saída de 35W, 45W, 50W, 60W, 90W, 100W e 130W oferece flexibilidade para diferentes necessidades de corte.

Os modernos tubos de corte a laser podem processar diferentes tipos de tubos e perfis, incluindo formas redondas, quadradas e retangulares, bem como uma variedade de materiais e espessuras de parede para acomodar os diversos requisitos do setor.

A tecnologia por trás dos lasers de tubo avançou significativamente, incorporando sistemas de 6 eixos com cabeçotes articulados que permitem configurações de corte complexas. Essa flexibilidade significa que os tubos de corte a laser podem lidar com trabalhos de todos os tamanhos, desde projetos de pequena escala até grandes aplicações industriais. Setores como engenharia mecânica, construção de sistemas e fabricação de móveis dependem muito desses tubos para suas necessidades de corte.

Em 2025, os modelos mais recentes de cortadores a laser de tubo utilizarão a tecnologia de laser de fibra, que oferece velocidades de corte mais rápidas e maior eficiência em comparação com os lasers CO₂ tradicionais. Esse salto tecnológico não apenas aumenta a produtividade, mas também abre novas possibilidades para trabalhos de design complexos e versáteis.

Principais benefícios do uso de tubos de corte a laser

A precisão oferecida pela tecnologia de corte de tubos a laser é incomparável. Com precisão micrométrica, essas máquinas superam os métodos de corte tradicionais, garantindo que cada corte seja o mais preciso possível. Esse nível de detalhe é essencial para os setores que exigem resultados consistentes e de alta qualidade. Em 2025, as máquinas de corte a laser de tubos se tornarão indispensáveis devido à sua precisão e eficiência inigualáveis.

Um dos principais benefícios do uso de lasers de tubo inclui:

- Eliminação de operações secundárias, como soldagem ou polimento

- Otimização do processo de produção

- Redução do tempo e dos custos gerais de fabricação

- Capacidade de criar designs e formas complexas sem trabalho de acabamento adicional

Esses fatores aumentam ainda mais a versatilidade e a eficiência do corte a laser de tubos e aumentam seu apelo.

Além disso, os lasers tubulares são incrivelmente versáteis, capazes de cortar uma variedade de materiais, incluindo diferentes ligas. Essa adaptabilidade os torna adequados para uma ampla gama de setores, desde o automotivo até dispositivos médicos. Os cortadores a laser de tubo avançados em 2025 contarão com recursos multieixos, permitindo uma versatilidade ainda maior no corte de formas e perfis complexos.

Aplicações de corte de tubos

A tecnologia de corte de tubos a laser oferece uma ampla gama de aplicações em vários setores, tornando-a uma ferramenta essencial para a fabricação moderna. Desde a engenharia mecânica e a construção de sistemas até o setor de móveis, a capacidade de processar tubos e perfis com alta precisão e qualidade transformou a maneira como as empresas produzem peças. O corte a laser de tubos permite a criação de componentes intrincados de tubos e perfis, suportando tudo, desde simples orifícios de montagem até características arquitetônicas complexas.

As oficinas e os fabricantes de setores como maquinário agrícola, produção de estruturas e construção de estruturas leves se beneficiam das máquinas de corte de tubos a laser que podem lidar com uma ampla gama de diâmetros, espessuras e materiais de tubos. Essa versatilidade permite a produção eficiente de peças padrão e personalizadas, garantindo que cada peça atenda a rigorosos padrões de qualidade. Como resultado, os serviços de corte de tubos a laser são muito procurados para a produção de peças que exigem precisão, repetibilidade e um acabamento de alta qualidade.

Independentemente de você precisar produzir um único protótipo ou um grande lote de componentes, a tecnologia de corte de tubos a laser oferece a flexibilidade e a qualidade necessárias para uma ampla gama de aplicações de corte de tubos.

Tubos de laser na fabricação moderna

No atual ambiente de fabricação em ritmo acelerado, os tubos de laser são ferramentas indispensáveis para alcançar o máximo de produtividade e qualidade superior do produto. Integrados aos lasers de tubo, esses componentes são projetados para lidar com uma ampla gama de tamanhos, formatos e materiais de tubos, o que os torna essenciais para diversas aplicações de corte de tubos.

Os tubos a laser permitem que os fabricantes produzam ângulos precisos, bordas chanfradas e perfis complexos em tubos, mantendo alto rendimento e qualidade consistente. A conexão entre os tubos a laser e os lasers de tubo avançados agiliza todo o processo de produção, reduzindo o tempo de processamento e aumentando a eficiência de cada etapa. Essa sinergia permite que as empresas produzam projetos complexos de corte de tubos que atendem às especificações mais exigentes.

Com sua capacidade de se adaptar a vários perfis e materiais, os tubos a laser se tornaram uma pedra angular da fabricação moderna, permitindo que as empresas forneçam produtos de alta qualidade de forma rápida e confiável.

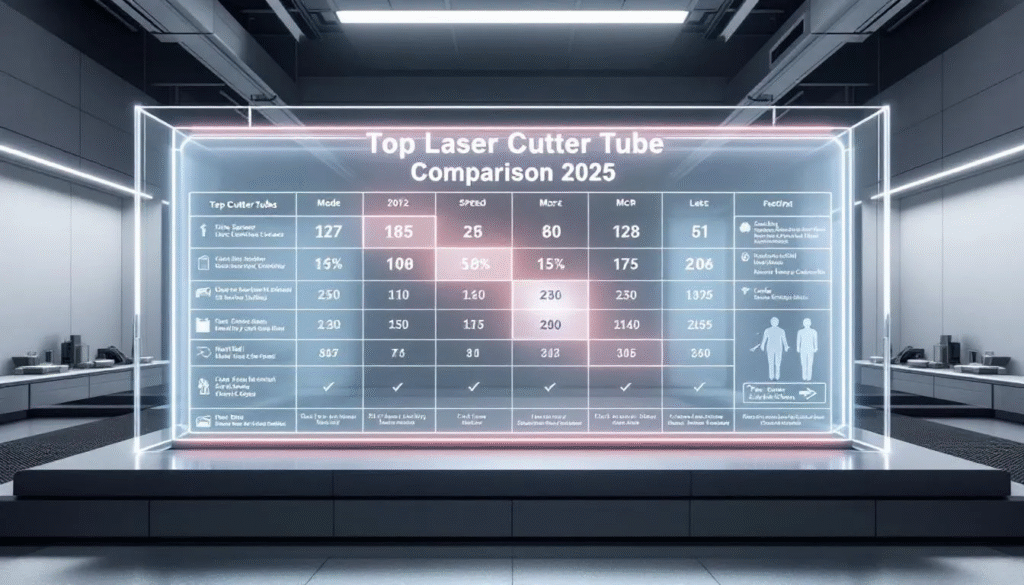

Principais modelos de tubos de corte a laser para 2025

A escolha do modelo certo de tubo de corte a laser é fundamental para otimizar a produtividade e fornecer resultados de qualidade em vários setores. O mercado em 2025 apresenta uma variedade de modelos inovadores adaptados a diferentes aplicações. Nesta seção, exploraremos os três principais modelos que se destacam por seu desempenho, custo-benefício e tecnologia avançada. Muitos dos principais modelos de tubos para cortadores a laser são mantidos em estoque para envio imediato, garantindo tempos mínimos de espera para os clientes.

O Trumpf TruLaser Tube 7000, equipado com um laser de CO₂ de 10 kW, é conhecido por seus cortes 3D altamente detalhados e pela precisão, o que o torna ideal para projetos complexos e produção de alta qualidade.

Se você está procurando alto desempenho, confiabilidade econômica ou tecnologia avançada e versatilidade, esses modelos têm algo a oferecer. Vamos nos aprofundar nas especificidades de cada modelo para entender por que eles são as melhores opções para 2025.

Modelo A: alto desempenho e eficiência

Aqueles que buscam produtividade máxima e alto desempenho encontrarão no TruLaser Tube 5000 fiber uma opção de destaque. Utilizando lasers de estado sólido, esse modelo foi projetado para corte em alta velocidade com precisão excepcional. Especialmente adequado para tubos XXL, ele lida com facilidade até mesmo com os projetos mais exigentes.

A capacidade de peso dessas máquinas permite que elas manuseiem tubos e perfis pesados, tornando-as adequadas para aplicações industriais exigentes.

Destacando-se nessa categoria, o TruLaser Tube 7000 foi projetado especificamente para a máxima produtividade com tubos grandes. Os fios pré-conectados no tubo do laser de CO2 TEN-HIGH 50W aumentam ainda mais a facilidade de uso, tornando a instalação simples e minimizando o tempo de inatividade.

Esses recursos contribuem coletivamente para a criação de uma ampla variedade de peças com eficiência, reduzindo o tempo de troca e garantindo que a sua linha de produção funcione de forma suave e eficaz, o que pode ser quantificado por vários fatores de serviço de processamento. Cada etapa desse processo requer ferramentas que são cruciais para o desempenho ideal.

Modelo B: econômico e confiável

Quando se trata de equilibrar custo e confiabilidade, o BLM GROUP LT8.20 se destaca. Esse modelo oferece um preço competitivo sem comprometer o desempenho. Ele foi projetado para processar tubos livres de até 300 mm de diâmetro e tamanho com eficiência, o que o torna adequado para várias aplicações.

Os usuários relataram experiências satisfatórias com o atendimento ao cliente do fabricante, observando respostas rápidas e soluções eficazes para quaisquer problemas relacionados aos seus tubos de laser. Essa confiabilidade garante que você obtenha o máximo de produtividade do seu investimento e, ao mesmo tempo, mantenha os custos operacionais baixos.

Investir no BLM GROUP LT8.20 significa adquirir uma máquina econômica e confiável, garantindo interrupções mínimas em sua linha de produção.

Modelo C: Tecnologia avançada e versatilidade

O BLM LT8 20 é um divisor de águas para aqueles que buscam aproveitar o que há de mais moderno em tecnologia de corte. Os principais recursos incluem:

- Um potente laser de 4000 watts que oferece precisão e velocidade inigualáveis

- Integração de tecnologia avançada

- Versatilidade no manuseio de diversos materiais e espessuras de parede

O TruLaser Tube 7000 também representa o auge da tecnologia avançada, utilizando um laser de estado sólido para aumentar a precisão e a eficácia das operações de corte de tubos. A capacidade desse modelo de processar tubos e perfis de diferentes materiais e espessuras demonstra sua versatilidade em diversas aplicações.

Esses recursos avançados tornam o BLM LT8 20 e o TruLaser Tube 7000 as escolhas ideais para os setores que exigem tecnologia de ponta e versatilidade em seus processos de fabricação.

Principais recursos das máquinas de corte a laser

As modernas máquinas de corte a laser de tubos são projetadas com recursos que maximizam a produtividade e proporcionam qualidade excepcional. Um dos atributos de destaque é sua capacidade de acomodar uma ampla gama de tamanhos e materiais de tubos, permitindo que os fabricantes lidem com uma variedade de projetos com uma única máquina. A tecnologia avançada, como os lasers de tubo de 6 eixos, permite a criação de projetos complexos de corte de tubos, incluindo ângulos precisos e bordas chanfradas, com precisão notável.

Essas máquinas são projetadas para serem eficientes, com peso e tamanho compactos que facilitam sua integração às linhas de produção existentes. Seus requisitos de manutenção limitados e o consumo reduzido de energia contribuem para reduzir os custos operacionais, tornando-as uma solução econômica para empresas que desejam melhorar seus processos de produção. A capacidade de produzir cortes de alta qualidade em tubos e perfis, combinada com a flexibilidade de lidar com diferentes materiais, garante que as máquinas de corte a laser para tubos continuem sendo uma ferramenta essencial nos setores em que a precisão e a produtividade são fundamentais.

Fatores a serem considerados na escolha de um tubo de corte a laser

A seleção do tubo de corte a laser correto envolve várias considerações importantes:

- O tipo e as dimensões do tubo a ser cortado são cruciais.

- Máquinas diferentes atendem a vários materiais, como aço inoxidável e alumínio, o que afeta a potência do laser necessária.

- O comprimento da cauda é importante para otimizar o uso do material.

- A capacidade de cortar chanfros aumenta a eficiência nos processos de soldagem subsequentes.

Preste muita atenção às medidas de isolamento e segurança, especialmente ao manusear o polo positivo em sistemas elétricos e de resfriamento, para evitar riscos. Muitos tubos de corte a laser modernos incluem travas de segurança que desligam automaticamente o laser se o gabinete for aberto, aumentando a segurança do operador. Além disso, a instalação de um tubo de laser de CO2 requer conexões adequadas para os polos positivo e negativo, bem como um suprimento confiável de água de resfriamento para manter o desempenho ideal e evitar o superaquecimento.

A marca e a potência do laser afetam diretamente o desempenho. Os lasers de fibra geralmente são preferidos para o corte de metais devido à sua eficiência. Além disso, as dimensões físicas do cortador a laser devem estar alinhadas com o espaço de trabalho disponível para garantir a instalação e a funcionalidade adequadas. O comprimento e o diâmetro dos tubos de laser de CO2, em particular, devem ser compatíveis com o espaço de instalação da máquina de corte a laser para garantir uma integração perfeita.

A compatibilidade com os padrões locais de fornecimento de energia é essencial para evitar problemas operacionais. Além disso, o sistema de controle e os recursos de software devem suportar recursos avançados para operações simplificadas e conexão com sistemas existentes.

Aumento da produtividade com tubos de corte a laser

O aumento da produtividade com tubos de corte a laser consiste em aproveitar seus recursos avançados para acelerar a produção e reduzir os custos. A tecnologia de corte de tubos a laser acelera significativamente os tempos de produção, permitindo o corte contínuo sem interrupções. Essa eficiência é aprimorada ainda mais pelos recursos de automação que minimizam a necessidade de trabalho manual.

A redução do desperdício de material é outro benefício significativo, levando a custos de produção mais baixos e práticas mais sustentáveis que economizam recursos. A precisão e a velocidade do corte influenciam diretamente a qualidade geral do processo de fabricação, garantindo que cada produto seja produzido de acordo com os mais altos padrões.

Setores como o automotivo e o de HVAC se beneficiam muito dos recursos de detalhamento intrincado dos cortadores de tubos a laser limitados, que permitem a criação de projetos complexos com o mínimo de erros.

Precauções de segurança no corte a laser

Garantir a segurança ao trabalhar com máquinas de corte de tubos a laser é fundamental para qualquer operação. Os operadores devem sempre usar equipamentos de proteção adequados, incluindo óculos e luvas de segurança, para se protegerem da exposição ao laser e das bordas afiadas dos tubos. Manter a ventilação adequada no espaço de trabalho também é fundamental, pois ajuda a remover fumaça e partículas geradas durante o processo de corte.

É importante seguir as diretrizes do fabricante para o tubo de laser e para a máquina, inclusive as rotinas regulares de manutenção e inspeção. Essa abordagem proativa ajuda a evitar o mau funcionamento do equipamento e reduz o risco de acidentes. Muitas máquinas modernas de corte de tubos a laser, como as da TRUMPF e do BLM GROUP, são equipadas com recursos de segurança integrados, como botões de parada de emergência e escudos de proteção, aumentando ainda mais a segurança no local de trabalho.

Ao aderir a essas precauções de segurança, as empresas podem criar um ambiente seguro para suas equipes, garantindo que todas as etapas do processo de corte de tubos a laser sejam realizadas com segurança e eficiência.

Dicas de manutenção para prolongar a vida útil do tubo do cortador a laser

A manutenção adequada é fundamental para prolongar a vida útil dos tubos do cortador a laser e garantir o desempenho ideal. A lubrificação regular das peças móveis reduz o atrito e o desgaste, prolongando a vida operacional da máquina. A inspeção e a substituição regular do líquido de arrefecimento ajudam a evitar o superaquecimento e possíveis danos ao tubo do laser.

Manter o sistema de exaustão limpo mantém o fluxo de ar, reduzindo o risco de acúmulo de fumaça e otimizando o desempenho do corte. O uso de água destilada no sistema de resfriamento evita o acúmulo de minerais, que pode levar à falha do tubo do laser. Após o revestimento, a potência de saída do laser de um tubo de laser de CO2 pode ser aumentada em pelo menos 5% em comparação com os tubos não revestidos, o que o torna um aprimoramento que vale a pena para melhorar a eficiência.

A limpeza diária de lentes e sistemas ópticos é fundamental para manter a clareza e evitar danos permanentes causados pelo acúmulo de detritos. A realização de inspeções diárias dos componentes externos e internos da máquina pode identificar pequenos problemas antes que eles se agravem, garantindo operações suaves e eficientes.

Comentários e avaliações de clientes

O feedback dos clientes é inestimável para avaliar o desempenho e a confiabilidade dos tubos de corte a laser. Muitos clientes apreciam a garantia de qualidade fornecida pela TEN-HIGH, pois cada tubo de laser é testado antes do envio, aumentando a confiança do usuário. Esse rigoroso processo de testes garante que o produto que você recebe é da mais alta qualidade.

Os clientes também gostam de ter acesso a informações detalhadas sobre políticas de garantia, especificações de produtos e suporte, o que os ajuda a tomar decisões de compra informadas.

Os usuários relataram altos níveis de satisfação com o desempenho de vários tubos de corte a laser, demonstrando sua confiabilidade e eficácia em aplicações do mundo real. Essas avaliações positivas desempenham um papel importante na influência das decisões de compra, orientando os possíveis compradores para modelos que comprovadamente apresentam bom desempenho em campo.

Em geral, as avaliações dos clientes são uma ferramenta poderosa para saber como os diferentes modelos de tubos de corte a laser se comparam em termos de qualidade, desempenho e atendimento ao cliente.

Serviços e suporte de corte a laser

Os principais fornecedores de serviços de corte de tubos a laser, como a Totten Tubes, oferecem uma ampla gama de soluções projetadas para ajudar os clientes a obter o máximo de produtividade e qualidade. Essas empresas fornecem suporte abrangente, incluindo assistência técnica, serviços de manutenção e treinamento de operadores, garantindo que os clientes possam operar suas máquinas de corte de tubos a laser com confiança e eficiência.

Além do suporte técnico, muitas empresas oferecem uma ampla gama de serviços de corte a laser, que vão desde o corte de tubos e a criação de perfis até a gravação e a produção de peças personalizadas. Ao aproveitar a tecnologia avançada e as ferramentas especializadas, esses serviços permitem que os clientes produzam peças de alta qualidade com tempo e custos de produção reduzidos. Isso não apenas ajuda os clientes a se manterem competitivos, mas também garante que seus produtos atendam aos mais altos padrões de precisão e durabilidade.

Ao escolher um fornecedor que ofereça serviços e suporte robustos, os clientes podem otimizar suas operações de corte de tubos, reduzir o tempo de inatividade e produzir consistentemente peças que atendam às suas especificações exatas.

Futuro da tecnologia de corte a laser

O futuro da tecnologia de corte de tubos a laser está pronto para revolucionar a fabricação com avanços contínuos no projeto de máquinas, fontes de laser e software inteligente. Como a demanda por tubos e perfis cortados a laser continua a crescer, as empresas estão investindo em pesquisa e desenvolvimento para criar máquinas mais rápidas, mais precisas e mais produtivas do que nunca.

Tecnologias emergentes, como inteligência artificial, aprendizado de máquina e Internet das Coisas (IoT), estão sendo integradas às máquinas de corte de tubos a laser, tornando-as mais autônomas e conectadas. Isso significa que os fabricantes podem produzir peças de alta qualidade com prazos de entrega reduzidos, economizar em custos operacionais e reduzir o desperdício de material. A capacidade de criar perfis e peças complexas com o mínimo de intervenção manual está transformando os setores, desde o automotivo e aeroespacial até a produção de energia renovável e veículos elétricos. Os tubos de metal RF, outro tipo de tubo a laser, também são utilizados em várias operações, ampliando ainda mais a versatilidade da tecnologia de corte a laser.

À medida que a tecnologia de corte de tubos a laser continua a evoluir, as empresas que adotarem essas inovações se beneficiarão da qualidade aprimorada, da maior flexibilidade e da economia significativa de tempo e custo, garantindo que permaneçam na vanguarda do mercado global de fabricação.

Recursos adicionais para corte a laser

Para as empresas que desejam aprofundar seus conhecimentos sobre a tecnologia de corte a laser e suas aplicações, há uma grande variedade de recursos adicionais disponíveis. De tutoriais abrangentes e guias passo a passo a workshops interativos e conferências do setor, esses recursos fornecem informações valiosas sobre os últimos avanços e as práticas recomendadas no corte de tubos a laser.

As plataformas e os fóruns on-line oferecem oportunidades para que os clientes se conectem com especialistas do setor, compartilhem experiências e encontrem soluções para desafios específicos. Ao aproveitar esses recursos, as empresas podem aprender a otimizar seus processos de produção, reduzir custos e economizar tempo e dinheiro. O acesso a informações atualizadas permite que as empresas adicionem novos produtos e serviços, entrem em novos mercados e expandam sua base de clientes no competitivo mundo da manufatura.

Manter-se informado sobre as mais recentes tecnologias e serviços de corte a laser garante que as empresas permaneçam na vanguarda da inovação, melhorando continuamente suas operações e oferecendo valor excepcional aos clientes.

Resumo

Em resumo, os avanços nos tubos para cortadores a laser para 2025 oferecem benefícios incríveis em termos de precisão, eficiência e versatilidade. Não importa se você está procurando modelos de alto desempenho, como o TruLaser Tube 5000 fiber, opções econômicas, como o BLM GROUP LT8.20, ou tecnologia avançada e versatilidade com o BLM LT8 20, há um tubo de corte a laser para atender às suas necessidades específicas.

A escolha do modelo certo envolve a consideração de fatores como tipo e dimensões do tubo, potência do laser, confiabilidade da marca e compatibilidade com os padrões locais. A manutenção adequada é essencial para prolongar a vida útil dos tubos do cortador a laser e garantir um desempenho consistente.

Ao explorar as opções disponíveis, lembre-se de que o investimento no tubo de corte a laser correto pode aumentar significativamente a produtividade e a qualidade do produto, tornando-o uma adição interessante ao seu processo de fabricação.

Perguntas frequentes

Quais são os principais benefícios do uso de tubos de corte a laser?

Os principais benefícios do uso de tubos de corte a laser incluem a precisão micrométrica e a capacidade de criar projetos complexos sem a necessidade de operações secundárias ou trabalho de acabamento adicional. Essa eficiência aumenta a produtividade e melhora a qualidade do produto final.

Como faço para escolher o tubo de corte a laser certo para minhas necessidades?

Para escolher o tubo de corte a laser correto, priorize a potência do laser, as dimensões e a compatibilidade com seu equipamento e os padrões locais. Certifique-se de que a marca tenha uma reputação confiável e que o sistema de controle possa atender aos seus requisitos.

Que manutenção é necessária para prolongar a vida útil dos tubos do cortador a laser?

Para prolongar a vida útil dos tubos do cortador a laser, é fundamental realizar a lubrificação regular, inspecionar os níveis do líquido de arrefecimento, limpar o sistema de exaustão e o sistema óptico e realizar inspeções diárias. A adesão a essas práticas de manutenção garantirá o desempenho ideal e a longevidade de seu equipamento.

Quais setores se beneficiam mais dos tubos para cortadores a laser?

Setores como engenharia mecânica, automotivo, fabricação de móveis, HVAC e construção de sistemas se beneficiam muito com a precisão e a versatilidade dos tubos de corte a laser. Essa tecnologia aprimora suas capacidades e eficiência de produção.

Quais são os principais modelos de tubos de cortadores a laser para 2025?

Para 2025, o TruLaser Tube 5000 fiber, o BLM GROUP LT8.20 e o BLM LT8 20 são modelos de tubo de corte a laser de destaque, cada um oferecendo desempenho excepcional e tecnologia avançada adequada a várias necessidades. A priorização desses modelos garantirá seu acesso às mais recentes inovações em corte a laser.