Encontrar um fornecedor confiável de tubos para laser de CO2 afeta diretamente o desempenho e a vida útil do seu sistema de laser. Neste artigo, analisamos os principais fornecedores, como Reci, EFR e SPT Laser, e discutimos o que faz com que seus produtos se destaquem. Saiba mais sobre os principais recursos e dicas para selecionar o melhor fornecedor para atender às suas necessidades.

Principais conclusões

- A China é o principal país para Fabricação de tubos de laser de CO2, A empresa é uma das principais marcas, como Reci, EFR e SPT Laser, conhecida por sua confiabilidade e tecnologia avançada.

- Os principais recursos dos tubos de laser de CO2 de alta qualidade incluem qualidade superior do feixe, longevidade, estabilidade em condições operacionais e eficiência energética, que são essenciais para o desempenho ideal.

- Ao escolher um fornecedor de tubos de laser de CO2, considere a reputação, as ofertas de garantia, a linha de produtos e os preços competitivos para garantir a confiabilidade e a adequação para aplicações específicas.

Principais fornecedores de tubos para laser de CO2

A escolha do fornecedor certo de tubos para laser de CO2 afeta significativamente a longevidade e o desempenho de seus sistemas de laser. A China, reconhecida como a maior Tubo de laser de vidro CO2 A Reci, Inc., base de fabricação global, produz mais de 90% de tubos de laser de vidro CO2 e abriga algumas das marcas mais famosas do mercado, incluindo Reci, EFR e SPT Laser. Essas empresas são conhecidas por sua confiabilidade, inovação e tecnologia avançada na produção de tubos de laser de alta qualidade. Cada empresa está localizada em centros industriais estratégicos na China, o que contribui para sua reputação de qualidade e avanço tecnológico.

Os tubos de vidro de CO2 normalmente têm uma vida útil de 2.000 a 4.000 horas, o que faz com que sua durabilidade seja uma consideração importante ao selecionar um fornecedor. A potência dos tubos de laser de CO2 pode variar significativamente de acordo com o modelo, indo de 30W a 200W, permitindo diversas aplicações em todos os setores.

Essas empresas fornecem tubos de laser de CO2 para todo o mundo por meio de uma rede de distribuidores autorizados, garantindo acessibilidade e suporte globais. Elas também exportam tubos de laser de CO2 para mercados internacionais, expandindo ainda mais seu alcance global.

Tecnologia de laser Reci

A Reci Laser Technology é conhecida por produzir tubos de laser de CO2 de alta qualidade. Suas técnicas avançadas de fabricação, como o uso de máquinas CNC de alta precisão para peças de metal, garantem precisão e durabilidade. A Reci é a marca de tubos de laser mais popular do mundo, um status alcançado por meio de inovação contínua e garantia de qualidade. Uma das inovações notáveis da Reci é a terceira geração de tubos de laser de CO2, que emprega uma nova tecnologia de queima para unir componentes de metal e vidro de forma eficaz, resultando em uma potência de saída 1020w maior do que a das marcas concorrentes. Essa melhoria significativa foi obtida por meio de pesquisa e desenvolvimento contínuos. Ao longo de uma década, a Reci Laser desenvolveu produtos para aprimorar seus tubos de laser de vidro CO2, obtendo melhorias significativas na qualidade.

Os tubos de laser de CO2 da Reci incluem uma garantia de 18 meses, demonstrando a confiança do fabricante na longevidade e estabilidade de seus produtos. Sua equipe profissional de suporte pós-venda aumenta a satisfação do cliente, oferecendo assistência com conhecimento sobre lasers e sistemas relacionados.

Laser EFR

Com quase 20 anos de experiência, a EFR Laser construiu uma reputação de engenharia de precisão em tubos de laser de CO2. Os principais recursos de seus produtos incluem:

- Estabilidade garantida pela tecnologia de vedação de vidro a metal, melhorando o desempenho e a longevidade

- Os tubos de laser de CO2 da série F oferecem uma potência de saída de até 200 W

- Os tubos de laser de CO2 F2 e F4 são conhecidos por seu excelente desempenho de gravação

- Adequado para várias aplicações exigentes

- Os lasers da série EF podem atingir até 200W de potência, o que é 30% mais do que os tubos de laser tradicionais, proporcionando maior eficiência e desempenho.

O tubo de laser da série CL da EFR, com potências acima de 70W e superiores a 100W para a série CL de 1.600 mm, demonstra o compromisso da EFR com o alto desempenho e a durabilidade. O tubo de laser da série R também oferece uma notável melhoria de potência de 20%, garantindo uma operação eficiente e confiável.

Laser SPT

A SPT Laser oferece uma variedade de tubos avançados de laser de CO2, atendendo a mercados como Vietnã, Brasil, Paquistão e Estados Unidos. Muitas fábricas chinesas de tubos de laser, incluindo a SPT, fornecem tubos de laser de alta qualidade com períodos de garantia mais longos, aumentando seu apelo para clientes globais. Sua popularidade é uma prova da qualidade e da confiabilidade de seus produtos, que são projetados para atender às diversas necessidades de sua base global de clientes. Os fabricantes chineses são reconhecidos por fornecer soluções econômicas de tubos de laser para usuários globais, solidificando ainda mais sua posição no mercado internacional.

Principais recursos dos tubos de laser de CO2 de alta qualidade

Projetados para precisão, velocidade e durabilidade, os tubos de laser de CO2 de alta qualidade se destacam por sua qualidade superior de feixe, longevidade, longa vida útil, estabilidade e eficiência energética, além de uma baixa taxa de falhas, o que garante um desempenho consistente em ambientes exigentes. Os tubos de laser de CO2 vedados aumentam ainda mais a confiabilidade, tornando-os ideais para uso contínuo e exigente.

O reconhecimento desses recursos ajuda a selecionar os melhores tubos de laser de CO2 para aplicações específicas.

Qualidade do feixe

A qualidade do feixe é fundamental para a gravação e o corte precisos. A qualidade superior do feixe permite um trabalho detalhado, essencial para aplicações de alta precisão. Os tubos de laser de CO2 são frequentemente testados quanto à qualidade do feixe para garantir um determinado modo de operação, o que é fundamental para obter resultados consistentes e confiáveis em tarefas exigentes.

Ao trabalhar em projetos complexos ou cortes de alta precisão, a qualidade do feixe de seu tubo de laser de CO2 afeta significativamente os resultados finais.

Longevidade e estabilidade

A longevidade e a estabilidade dos tubos de laser de CO2 são influenciadas por seus materiais de construção e condições operacionais. Os designs de metal-cerâmica contribuem significativamente para a estabilidade térmica e a vida útil, garantindo que os tubos possam suportar ambientes exigentes. A manutenção de uma temperatura operacional ideal entre 18°C e 25°C (64°F e 77°F) é essencial para evitar o superaquecimento e garantir um desempenho estável.

Sistemas de resfriamento adequados são essenciais para manter a estabilidade dos tubos de laser de CO2. Manter a temperatura da água entre 60 e 70°F ajuda a evitar o superaquecimento, protegendo os tubos e mantendo a eficiência. Seguir essas práticas garante uma vida útil mais longa e um desempenho confiável.

Eficiência energética

O uso eficiente da potência de saída é uma marca registrada dos tubos de laser de CO2 de alta qualidade. A otimização do uso da energia reduz os custos operacionais e melhora o desempenho geral, tornando esses tubos uma opção econômica. O investimento em tubos de laser eficientes permite que as empresas economizem nos custos de eletricidade e, ao mesmo tempo, aumentem a capacidade de produção.

Escolhendo o fornecedor certo de tubos para laser de CO2

A escolha do fornecedor certo de tubos para laser de CO2 garante a confiabilidade e o desempenho de seus sistemas de laser. Considere a reputação do fornecedor, a garantia e o suporte, a linha de produtos e o preço. As opções de personalização aumentam a compatibilidade com diferentes sistemas de laser e necessidades do usuário, facilitando a combinação perfeita para requisitos específicos. Alguns fornecedores também oferecem soluções OEM e personalizadas de tubos de laser de CO2.

A avaliação cuidadosa desses aspectos ajuda a tomar uma decisão informada que atenda às necessidades específicas e se alinhe às especificações do modelo central para desenvolver novos acessórios, proporcionando uma vantagem.

Garantia e suporte

A garantia e o suporte pós-venda são componentes essenciais de um fornecedor confiável de tubos de laser de CO2. Avaliar a reputação de um fornecedor e o feedback dos clientes fornece informações valiosas sobre sua confiabilidade e qualidade. Termos de garantia apropriados e suporte confiável aumentam significativamente a longevidade e o desempenho dos tubos de laser de CO2, assegurando a satisfação a longo prazo.

Gama de produtos e personalização

Uma ampla seleção de tubos de laser de CO2 ajuda os clientes a encontrar soluções adaptadas a várias aplicações e materiais. As opções de personalização aumentam a compatibilidade com diferentes sistemas de laser e necessidades do usuário, facilitando a combinação perfeita para requisitos específicos.

Preços competitivos

Preços competitivos são fundamentais para tornar os investimentos em tubos de laser de CO2 atraentes e econômicos. A compreensão dos fatores que afetam os preços, como os recursos do produto e os termos de garantia, ajuda os compradores a tomar decisões informadas e a aumentar a relação custo-benefício.

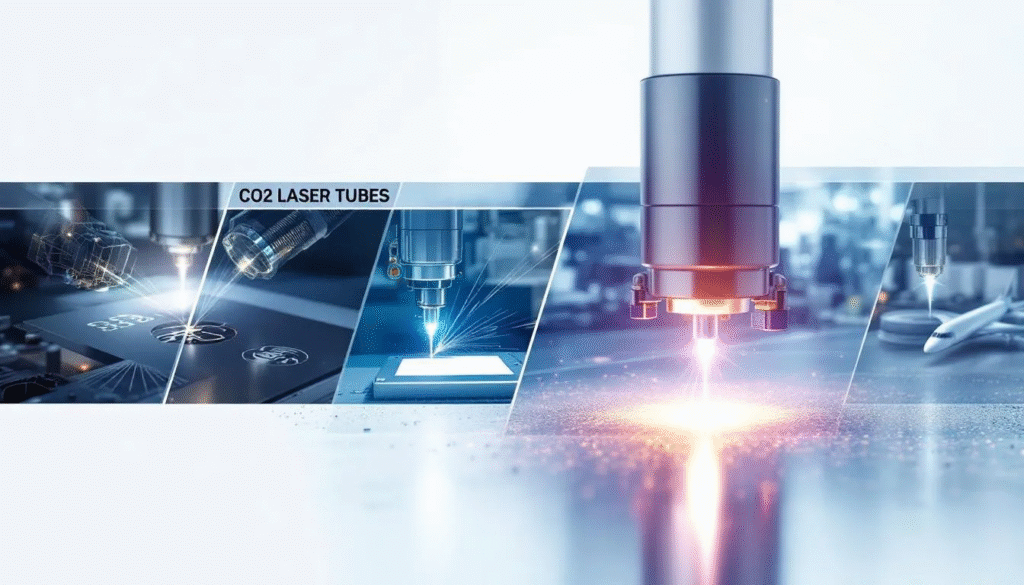

Aplicações dos tubos de laser de CO2

Os tubos de laser de CO2 são amplamente utilizados em vários setores por sua precisão e eficiência nas tarefas de corte e gravação. Esses tubos são comumente encontrados em máquinas de gravação a laser e máquinas de marcação a laser, atendendo a diferentes setores, como publicidade, sinalização, manufatura e pesquisa científica. Sua versatilidade os torna indispensáveis em aplicações de fabricação, médicas e de pesquisa, melhorando significativamente os recursos do processo.

Os lasers de CO2 com tubo de vidro são econômicos e amplamente usados para aplicações de corte, enquanto os tubos de RF oferecem qualidade superior de gravação, durabilidade e segurança, tornando-os adequados para ambientes profissionais. A tecnologia RF oferece qualidade de feixe aprimorada e uma vida útil mais longa, com tubos RF de CO2 geralmente excedendo 10.000 horas de operação. Os tubos de laser de vidro, por outro lado, são mais econômicos, com preços que variam de $400 a $1.500, o que os torna uma opção atraente para compradores preocupados com os custos.

Corte e gravação

Tubos de laser de CO2 são excelentes para a gravação a laser em vários materiais, proporcionando alta precisão para projetos detalhados. Eles são especialmente eficazes para o corte:

- Acrílico

- Madeira

- Couro

- Papel

Esses tubos oferecem precisão e velocidade para bordas limpas e designs detalhados. Os tubos a laser CO₂ são amplamente utilizados em setores como vestuário, couro, presentes, sinalização publicitária, modelagem arquitetônica, impressão e embalagem, eletrônicos e peças automotivas, demonstrando sua versatilidade e ampla gama de aplicações.

- Acrílico

- Madeira

- Couro

- Papel Esses tubos oferecem precisão e velocidade para bordas limpas e desenhos detalhados.

Medicina e manufatura

Na área médica, os tubos de laser de CO2 são usados para aplicações cirúrgicas e de resurfacing da pele, proporcionando precisão que minimiza os danos aos tecidos circundantes.

Na manufatura, esses tubos de laser são usados para corte a laser e soldagem de metais em aplicações industriais, melhorando a qualidade e a velocidade da produção. Os fabricantes de máquinas de corte a laser desempenham um papel fundamental na fabricação desses consumíveis para uso industrial com uma máquina a laser.

Pesquisa e desenvolvimento

Os tubos de laser de CO2 desempenham um papel crucial na pesquisa e no desenvolvimento, permitindo protótipos avançados e aprimorando as tecnologias existentes. Eles facilitam a exploração de novas tecnologias e o aprimoramento de processos existentes, o que os torna vitais em P&D.

Dicas de manutenção para tubos de laser de CO2

As práticas de manutenção regulares aumentam significativamente a vida útil dos tubos de laser de CO2, contribuindo para uma vida útil mais longa. Sistemas de resfriamento adequados, limpeza regular e manutenção de condições operacionais adequadas garantem o desempenho e a longevidade ideais. Além disso, o alinhamento dos tubos de laser de CO2 para um desempenho ideal é crucial e deve ser verificado regularmente.

A inspeção e a manutenção regulares das fontes de alimentação de laser também são essenciais para garantir uma operação estável e evitar paradas inesperadas.

Sistemas de resfriamento adequados

O resfriamento a água é fundamental para prolongar a vida útil de um tubo de laser de CO2. O resfriamento adequado evita o superaquecimento, protegendo os tubos e mantendo seu desempenho.

O uso de água destilada ou purificada nos sistemas de resfriamento evita o acúmulo de incrustações, mantendo a eficiência do tubo.

Limpeza regular

A limpeza das janelas dos tubos de laser de CO2 é fundamental para manter a qualidade e o desempenho ideais do feixe. Técnicas de limpeza adequadas, como evitar cotonetes que podem danificar a superfície, garantem a operação eficiente e a longevidade do tubo de laser.

Condições operacionais corretas

A manutenção de condições operacionais adequadas é fundamental para o desempenho ideal e a longevidade dos tubos de laser de CO2. Evite operar a máquina com potência máxima por períodos prolongados para evitar superaquecimento e garantir a operação dentro dos parâmetros especificados.

Precauções de segurança para o manuseio de tubos de laser de CO2

Ao manusear tubos de laser de CO2, a segurança deve ser sempre uma prioridade para evitar acidentes e lesões. A proteção adequada dos olhos, o armazenamento e o transporte seguros e o manuseio cuidadoso de componentes de alta tensão são medidas de segurança essenciais. O uso de um estojo de proteção para o transporte e o armazenamento seguros dos tubos de laser de CO2 também é altamente recomendado.

Proteção para os olhos

A proteção dos olhos é essencial ao operar um dispositivo a laser de CO2 para evitar lesões causadas pela exposição ao laser. O uso de óculos de segurança para laser projetados para o comprimento de onda específico do laser protege contra radiação prejudicial.

Armazenamento e transporte seguros

O armazenamento e o transporte seguros dos tubos de laser de CO2 são essenciais para evitar danos e manter a funcionalidade. As principais diretrizes incluem:

- Armazene em um ambiente com temperatura controlada, evitando extremos de temperatura ou umidade.

- Armazene os tubos na posição vertical para evitar vazamentos ou quebras.

- Rotule claramente os contêineres de armazenamento para garantir o manuseio e a identificação seguros.

Manuseio de alta tensão

O manuseio de componentes de alta tensão em tubos de laser de CO2 exige procedimentos de segurança rigorosos para proteção contra choques elétricos e falhas no equipamento. O aterramento e o isolamento adequados devem ser garantidos para evitar o contato acidental. Verificações regulares e o uso de equipamento de proteção individual (EPI) adequado são essenciais para proteger contra possíveis riscos elétricos.

Resumo

Em resumo, a seleção de um fornecedor de tubos de laser de CO2 de alta qualidade envolve a consideração de fatores como reputação, garantia, variedade de produtos e preço. Os principais recursos dos tubos de laser de alta qualidade, incluindo a qualidade do feixe, a longevidade e a eficiência energética, são essenciais para obter o desempenho ideal. A manutenção regular e a adesão às precauções de segurança garantem a longevidade e a confiabilidade desses componentes essenciais. Ao tomar decisões informadas, você pode aproveitar todo o potencial dos tubos de laser de CO2 para aprimorar seus projetos e operações.

Perguntas frequentes

Quais são os principais recursos que devem ser procurados em tubos de laser de CO2 de alta qualidade?

Ao selecionar tubos de laser de CO2 de alta qualidade, priorize a qualidade superior do feixe, a longevidade e a estabilidade, além da eficiência energética para garantir o desempenho ideal. Esses recursos são essenciais para obter resultados precisos e confiáveis em suas aplicações.

Por que é importante escolher um fornecedor confiável de tubos de laser de CO2?

A escolha de um fornecedor confiável de tubos para laser de CO2 é fundamental para garantir produtos de alta qualidade, garantias estendidas e suporte abrangente, o que contribui para o desempenho e a longevidade dos seus sistemas de laser. Essa decisão afeta diretamente sua eficiência operacional e a relação custo-benefício.

Como os tubos de laser de CO2 beneficiam os setores médico e de manufatura?

Os tubos de laser de CO2 beneficiam significativamente os setores médico e de manufatura, proporcionando precisão em aplicações cirúrgicas e tratamentos de pele, além de melhorar a qualidade e a eficiência nos processos de corte e soldagem de metais. Sua versatilidade os torna essenciais em ambos os setores.

Quais práticas de manutenção podem prolongar a vida útil dos tubos de laser de CO2?

Para prolongar a vida útil dos tubos de laser de CO2, garanta o resfriamento adequado, faça limpezas regulares e mantenha condições operacionais adequadas. Essas práticas são cruciais para o desempenho e a longevidade ideais.

Que precauções de segurança devem ser tomadas ao manusear tubos de laser de CO2?

Ao manusear tubos de laser de CO2, é fundamental usar proteção adequada para os olhos, manusear componentes de alta tensão com cuidado e seguir procedimentos seguros de armazenamento e transporte para evitar acidentes. A priorização dessas precauções aumentará a segurança e reduzirá os riscos durante a operação.