O laser tube 40W CO2 is an essential component for small laser machines, widely used by hobbyists and professionals alike. At Feiju Laser, we understand the importance of using high-quality Tubo de laser de CO2 de 40 W products to ensure optimal performance in laser engraving and cutting applications. For small business owners looking to upgrade their equipment, the laser tube 40W CO2 is a cost-effective solution that offers good value for money, making it an attractive choice for both hobbyists and business users. Its affordability compared to high-power industrial lasers makes it particularly accessible for beginners.

Whether you are working with wood, acrylic, or plastic, this guide covers everything you need to know about the laser tube 40W CO2, including power supply, cooling systems, installation, maintenance, and upgrades. Additionally, a 40W CO2 laser can engrave on various non-metallic materials, including acrylic, wood, glass, and leather, making it versatile for a wide range of projects. However, it is important to note that a 40W CO2 laser is not powerful enough to cut through raw metal and can only mark coated metals.

Understanding the Laser Tube 40W CO2

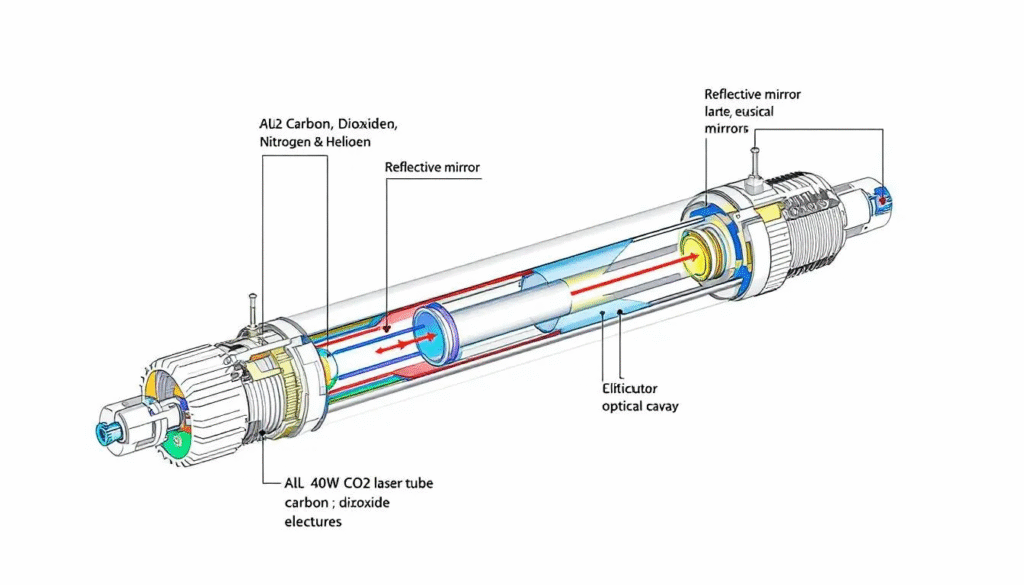

The core of any CO2 laser engraver or cutter is the Tubo de laser de CO2 de 40 W, which generates a laser beam with an output power of 40 watts. Laser tubes like the 40W CO2 are designed to engrave and cut a wide range of materials with precision, making them suitable for both detailed engraving and efficient cutting. A 40W CO2 laser is particularly suitable for detailed work on materials such as wood, acrylic, and leather. It is also capable of cutting up to 5mm acrylic and 6mm softwood, providing excellent functionality for small-scale projects. These laser tubes are compatible with various small laser machines and are known for their stability and long service life. The tube excites a gas mixture inside to produce a precise laser beam that travels through mirrors and lenses to the laser head, enabling fine control and high precision. The SPT laser tube offers superior heat dissipation for extended service life during operation.

Especificações do tubo de laser de CO2

When selecting a CO2 laser tube for your laser engraver or cutter, understanding the key specifications is essential for achieving reliable performance. A typical 40W CO2 laser tube, such as the SPT C35, measures 28.3 inches (720mm) in length and 2 inches (50mm) in diameter, making it a perfect fit for most small laser machines. The SPT C35 40W CO2 laser tube is specifically designed for small laser machines, particularly the K40 laser engraving machine. Weighing approximately 17.6 lbs (8 kg), this tube is designed for easy integration and stable operation.

The maximum output power of 40W ensures sufficient laser power for detailed engraving and cutting across a range of materials, while a power stability of ±5% helps maintain consistent results. The laser beam produced operates at a wavelength of 10,640 nm, ideal for processing wood, acrylic, and plastics. Operating a 40W CO2 laser tube at minimum power (10–40%) can yield a lifespan of 1,500–2,000 hours, depending on your power settings and cooling system. Using optimal power (40–70%) on a 40W CO2 laser tube results in a lifespan of 1,000–1,200 hours.

For optimal operation, keep the ambient humidity below 85% and monitor the temperature sensor to protect your investment. When it’s time for a replacement tube, always confirm compatibility with your power supply and machine specifications to ensure seamless installation and continued high-quality results.

Components and Accessories: Power Supply, Cooling, and Air Assist

Um confiável fonte de alimentação is crucial for maintaining consistent potência do laser in your machine. High-quality, well-shielded fontes de alimentação are essential for safety and reliability, helping to prevent issues such as unsafe voltages and poor wiring. The laser tube 40W CO2 requires a stable electrical current to function correctly, and all wires should be properly connected and shielded to prevent electrical hazards. Ground shielding should be used on high-voltage cables and power components to prevent electrical hazards.

Cooling is equally important; most tubes need resfriamento de água facilitated by a water pump circulating água destilada to prevent overheating, which can significantly reduce the tube’s lifespan. For even better results, use demineralized water in the cooling system to prevent mineral buildup. It is important to keep the laser tube cool by using chilled water or ice bottles to maintain optimal temperature and extend its life. Components like the water pump and air assist should be correctly installed to ensure safe and effective operation. An air pump provides assistência de ar to clear debris and minimize the risk of fire during operation. Additionally, an exhaust fan removes harmful fumes, and wearing safety goggles designed for CO2 lasers is essential for eye protection. A 40W CO2 laser tube is made from borosilicate glass and is designed for stability and durability, ensuring reliable performance over time. Power supplies used for CO2 lasers can deliver lethal voltages and must be handled with care.

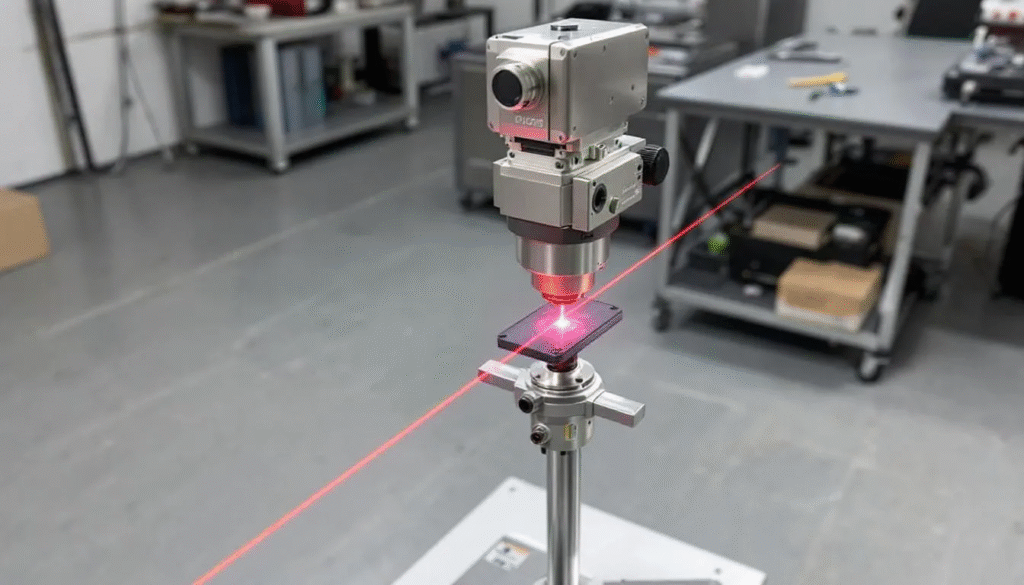

Laser Head and Mirror Alignment

Achieving precise and clean cuts or engravings with your CO2 laser tube depends heavily on the alignment of the laser head and mirrors. Proper mirror alignment ensures that the laser beam travels in a straight line through each mirror and passes directly through the center of the focusing lens and air assist hole. This careful setup prevents skewed lines and uneven engraving, maximizing the accuracy of your laser cutter.

A 40W CO2 laser can produce intricate designs and markings, making it ideal for creating custom items such as signs and stamps. Most mirror holders are designed to be adjustable both vertically and horizontally, allowing for fine-tuning during the alignment process. For added convenience, many users employ a dummy CO2 laser—such as a red diode laser housed in a tube matching the diameter of the actual laser tube—to pre-align the mirrors and lens before installing the real tube. This method helps you visualize the beam path and make necessary adjustments without risk.

Numerous online tutorials and video guides are available to walk you through the mirror alignment process step by step. Taking the time to ensure your laser head, mirrors, and lens are perfectly aligned will result in superior beam quality, cleaner cuts, and more precise engraving on all your projects.

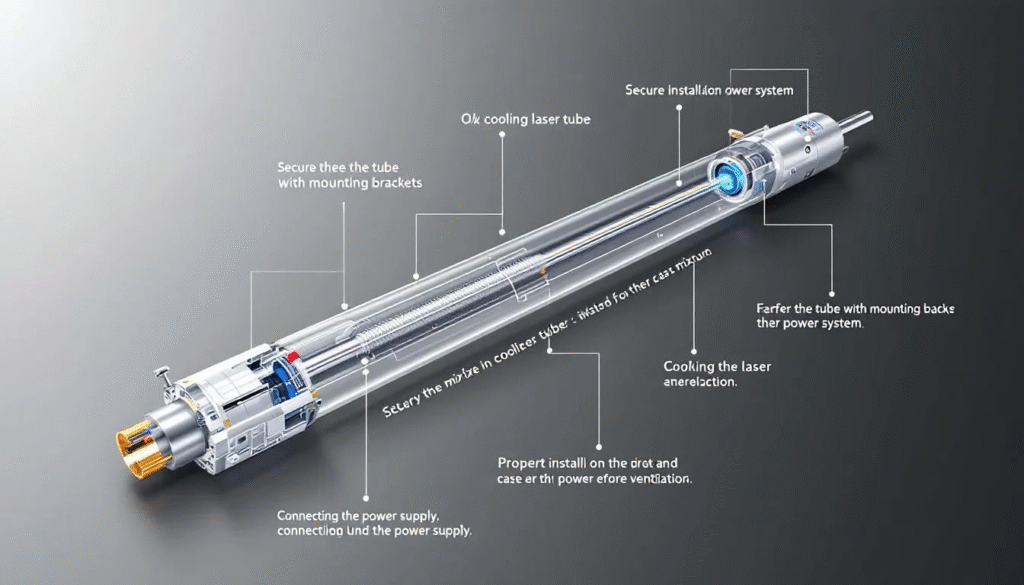

Installation and Maintenance Tips for Laser Tube 40W CO2

Installing a new Tubo de laser de CO2 demands careful handling and correct setup to ensure the machine operates in working order. Make sure the tube you purchased is compatible with your machine before installation. Connect the tube securely to the fonte de alimentação, install the water pump e air pump, and use only água destilada in the cooling system. The installation process for some 40W CO2 laser tubes is made easier through pre-connected wires, simplifying the setup for users.

Regular maintenance includes monitoring the temperature sensor, checking mirror alignment, and cleaning the lens e mirror to maintain beam quality. Worn or damaged tubes should be replaced promptly to maintain optimal performance. Misalignment or dirty optics can reduce potência do laser and affect the precisão of your cuts and engravings. Running a 40W CO2 laser tube at near maximum power (70–100%) reduces its lifespan to 400–600 hours. Perform a test run after maintenance to confirm proper operation, monitoring speed, e potência settings to optimize performance.

Replacement and Upgrades: When and How to Replace Your Laser Tube

Operating a CO2 laser machine requires strict safety measures. Always wear certified safety goggles to protect your eyes from the invisible laser beam. Ensure proper ventilation with an exhaust fan to clear toxic fumes; use a hose to direct the exhaust safely through a wall to the outside. For added safety, install a polycarbonate window in your laser enclosure so you can observe the laser operation without exposure to harmful light. Maintain the cooling system to prevent overheating, and monitor the assistência de ar to reduce fire hazards.

Using a honeycomb bed supports materials during cutting or engraving, improving airflow and minimizing back reflections that can damage the tube. Regularly inspect wires, hoses, and connections to avoid electrical hazards or leaks. Proper control and monitoring not only enhance precisão but also ensure safe operation. Toxic fumes may be produced when cutting certain plastics like ABS and polycarbonate, necessitating good ventilation. A fire extinguisher should be kept nearby when operating a CO2 laser cutter in case of emergencies.

Safety Considerations and Best Practices

Operating a CO2 laser machine requires strict safety measures. Always wear certified safety goggles to protect your eyes from the invisible laser beam. Ensure proper ventilation with an exhaust fan to clear toxic fumes; use a hose to direct the exhaust safely through a wall to the outside. For added safety, install a polycarbonate window in your laser enclosure so you can observe the laser operation without exposure to harmful light. Maintain the cooling system to prevent overheating, and monitor the assistência de ar to reduce fire hazards. Using a honeycomb bed supports materials during cutting or engraving, improving airflow and minimizing back reflections that can damage the tube. Regularly inspect wires, hoses, and connections to avoid electrical hazards or leaks. Proper control and monitoring not only enhance precisão but also ensure safe operation. Toxic fumes may be produced when cutting certain plastics like ABS and polycarbonate, necessitating good ventilation.

Conclusion: Laser Tube 40W CO2 – Key to Efficient Laser Engraving and Cutting

O laser tube 40W CO2 is vital for efficient laser engraving and cutting on various materials. At this point, it’s important to recognize that proper installation and upgrades can be challenging, and enrolling in a comprehensive course can provide step-by-step guidance for laser tube installation and upgrades. Understanding its operation, maintenance, and replacement helps you maximize your laser engraver or cutter’s performance and lifespan. Improved software can streamline operations and enhance the user experience with laser machines. By pairing a quality tube from Feiju Laser with a stable power supply, effective cooling, and air assist systems, you can achieve outstanding results in your laser projects. Investing time in proper installation and safety will ensure yourCO22 laser tube keeps your machine running smoothly for years to come.

For more information on laser tube care and upgrades, visite Feiju Laser’s official site and explore expert resources on laser cutter safety e CO2 laser technology.