Apakah Anda sedang mencari laser tabung CO2 untuk pemotongan dan pengukiran yang presisi? Laser serbaguna ini sangat cocok untuk mengerjakan kayu, akrilik, kaca, dan banyak lagi. Panduan ini akan menjelaskan apa itu laser tabung CO2, bagaimana cara kerjanya, dan apa yang harus diperhatikan saat memilihnya. Baca terus untuk menemukan opsi terbaik yang tersedia saat ini dan kiat-kiat untuk mendapatkan hasil maksimal dari laser Anda.

Hal-hal Penting yang Dapat Dipetik

- Laser tabung CO2 sangat penting untuk pemotongan dan pengukiran presisi pada berbagai bahan, menjadikannya berharga dalam industri seperti manufaktur dan seni.

- Faktor-faktor utama yang perlu dipertimbangkan ketika memilih laser tabung CO2 termasuk output daya, panjang dan diameter tabung, dan adanya kabel yang sudah disambungkan untuk menyederhanakan pemasangan.

- Umpan balik pelanggan menyoroti pentingnya keandalan dan kinerja pada laser tabung CO2, sekaligus mencatat area yang perlu ditingkatkan, seperti kerumitan perawatan dan kualitas pemotongan yang tidak konsisten.

Memahami Laser Tabung CO2

Laser tabung CO2 telah menjadi alat yang penting dalam berbagai industri karena presisi dan keserbagunaannya. Laser ini sangat populer karena kemampuannya untuk memotong dan mengukir berbagai macam bahan, mulai dari kayu dan akrilik hingga kaca dan kulit. Laser tabung CO2 umumnya digunakan dalam mesin pemotong laser untuk aplikasi profesional dan penghobi. Keserbagunaan ini menjadikannya aset yang tak ternilai di berbagai sektor, mulai dari manufaktur dan pendidikan hingga seni dan desain.

Beberapa merek terkemuka terkenal karena memproduksi laser tabung CO2, yang memenuhi kebutuhan dan preferensi yang berbeda. Memahami cara kerja laser ini, penggunaan umumnya, dan keuntungan yang ditawarkannya sangat penting untuk memilih model yang tepat untuk kebutuhan spesifik Anda.

Mari menyelami lebih dalam dunia laser tabung CO2 yang memukau.

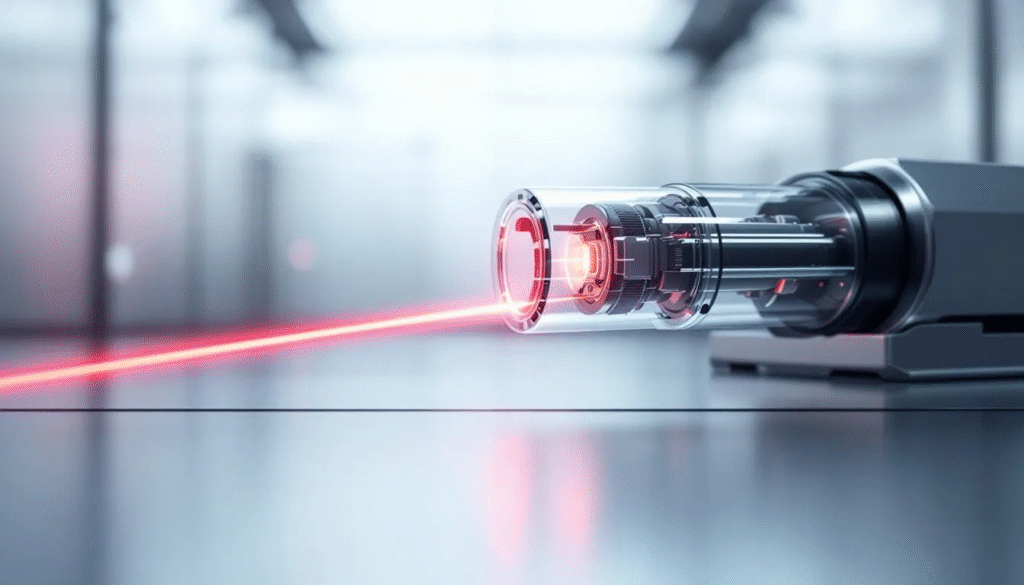

Cara Kerja Laser Tabung CO2

Inti dari laser tabung CO2 adalah campuran gas yang mencakup karbon dioksida, nitrogen, dan helium. Ketika tereksitasi secara elektrik, campuran ini menghasilkan sinar laser yang terfokus. Prosesnya melibatkan:

- Campuran gas dirangsang oleh energi listrik, menciptakan plasma di dalam tabung tertutup.

- Cahaya yang memperkuat plasma ini menghasilkan berkas cahaya yang koheren.

- Sinar cahaya yang koheren difokuskan melalui lensa untuk pemotongan dan pengukiran yang efektif.

Pengoperasian laser ini sangat bergantung pada stimulasi yang tepat dari campuran gas. Sinar laser yang dihasilkan dapat dikontrol secara halus untuk menghasilkan potongan dan ukiran yang rumit pada berbagai bahan. Tingkat kontrol dan presisi inilah yang membuat laser tabung CO2 sangat efektif untuk pekerjaan yang mendetail dan berkualitas tinggi.

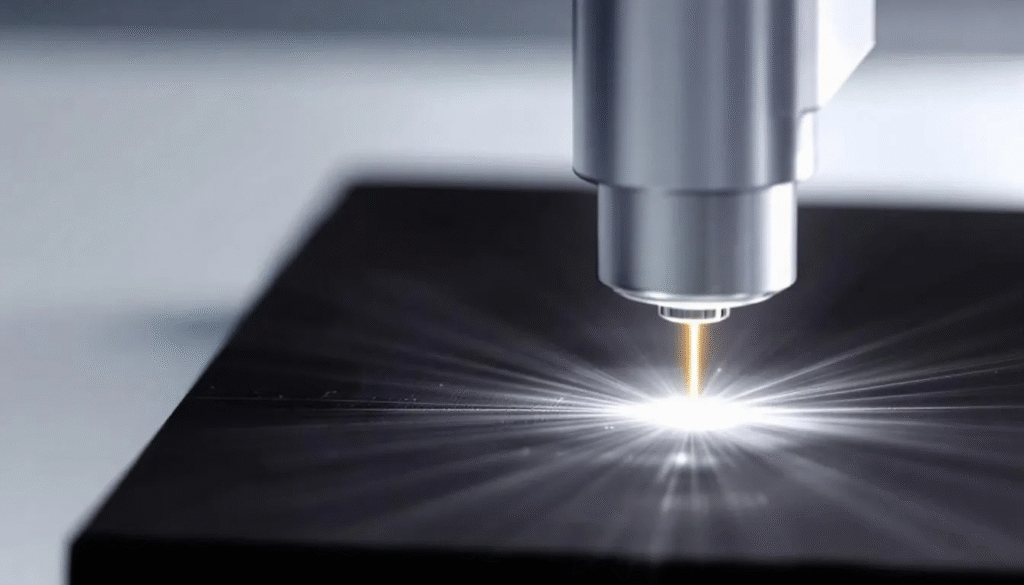

Penggunaan Umum untuk Laser Tabung CO2

Laser tabung CO2 sangat serbaguna, mampu memotong dan mengukir bahan seperti:

- Kayu

- Akrilik

- Kaca

- Kulit. Kemampuan penandaan berbasis panas memungkinkan presisi dan detail yang tinggi, sehingga cocok untuk aplikasi industri dan upaya artistik.

Laser ini digunakan di berbagai sektor. Di bidang manufaktur, laser ini membuat bagian dan komponen yang rumit, sementara di bidang seni, laser ini memungkinkan ukiran yang mendetail pada berbagai permukaan. Keserbagunaan ini adalah salah satu alasan utama mengapa laser tabung CO2 adalah alat yang sangat berharga di berbagai bidang.

Keuntungan Menggunakan Laser Tabung CO2

Salah satu manfaat utama laser tabung CO2 adalah kemampuannya untuk menghasilkan potongan yang rumit dan berkualitas tinggi dengan limbah material yang minimal. Efisiensi ini tidak hanya meningkatkan ketepatan pemotongan, tetapi juga membuat prosesnya lebih hemat biaya dengan mengurangi pemborosan material.

Selain itu, para pengguna sering menyoroti keefektifan laser CO2 dalam mencapai desain yang rumit. Baik untuk aplikasi industri atau artistik, presisi tinggi dan keserbagunaan laser ini membuatnya menjadi pilihan yang populer. Kemampuan mereka untuk menangani berbagai bahan dan mencapai hasil yang terperinci adalah bukti dari kinerja mereka yang unggul.

Fitur Utama yang Harus Diperhatikan dalam Laser Tabung CO2

Memilih tabung laser CO2 yang tepat melibatkan pertimbangan yang cermat terhadap berbagai fitur yang memengaruhi fungsionalitas dan kompatibilitasnya. Fitur-fitur ini membantu memilih laser yang memenuhi kebutuhan pemotongan dan pengukiran spesifik Anda, memastikan kinerja optimal dan umur panjang.

Laser tabung CO2 berkualitas tinggi diuji secara menyeluruh untuk kinerja dan keamanan sebelum dijual, memastikan keandalan dan daya tahan bagi pengguna.

Dari catu daya dan output hingga dimensi tabung dan kabel yang sudah disambungkan sebelumnya, setiap fitur memainkan peran penting dalam efektivitas laser secara keseluruhan. Mari pelajari fitur-fitur utama ini untuk lebih memahami apa yang harus dicari ketika memilih laser tabung CO2.

Catu Daya dan Output

Output daya laser tabung CO2 adalah faktor penting yang menentukan kemampuan pemotongan dan pengukirannya. Model dengan berbagai peringkat daya, seperti 40W, tersedia untuk memenuhi kebutuhan yang berbeda. Daya output tabung laser CO2 berkisar dari 40W hingga 150W, memberikan opsi untuk aplikasi ringan dan tugas berat. Mengevaluasi output daya, bersama dengan fitur lainnya, sangat penting untuk memastikan laser dapat menangani bahan yang Anda rencanakan untuk dikerjakan.

Output daya yang tidak memadai dapat menyebabkan masalah, seperti kualitas pemotongan atau pengukiran yang tidak konsisten. Memastikan catu daya laser mencukupi dan pengaturannya dikonfigurasi dengan benar untuk bahan yang sedang diproses sangat penting. Pemeriksaan dan penyesuaian secara teratur dapat membantu mempertahankan kinerja yang optimal.

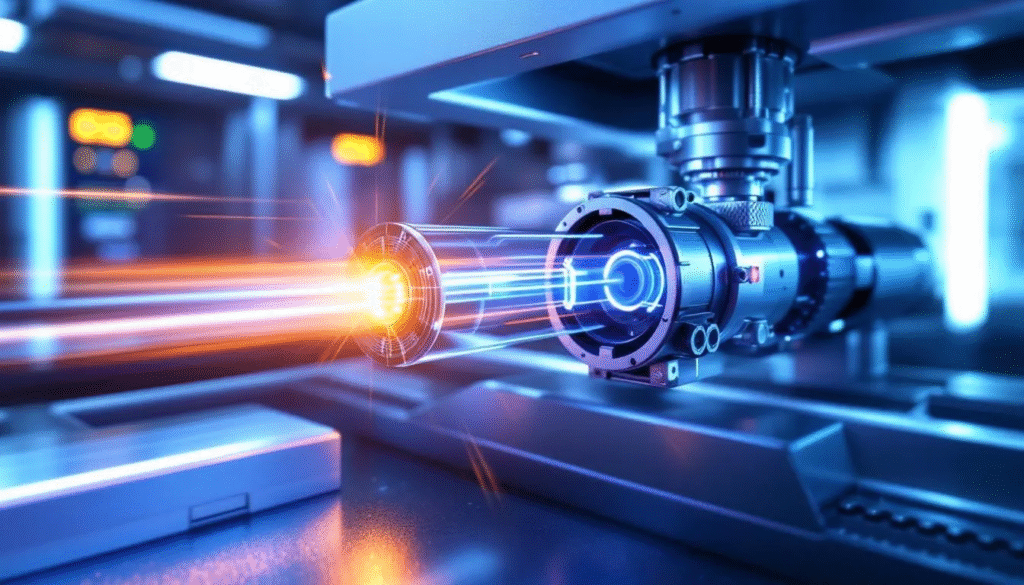

Panjang dan Diameter Tabung

Panjang dan diameter tabung laser CO2 secara signifikan memengaruhi kinerjanya. Tabung yang lebih panjang dapat memberikan kualitas sinar yang lebih konsisten pada jarak yang lebih jauh, yang sangat penting untuk aplikasi yang presisi. Selain itu, tabung yang lebih panjang dan lebih lebar umumnya meningkatkan output daya, memungkinkan laser untuk memotong bahan yang lebih padat secara lebih efektif. Panjang tabung laser CO2 umumnya bervariasi dari 700mm hingga 1650mm, menawarkan fleksibilitas untuk desain dan aplikasi mesin yang berbeda.

Dimensi tabung laser juga harus kompatibel dengan desain mesin pengukiran. Memastikan bahwa panjang dan diameter tabung sesuai dengan spesifikasi mesin sangat penting untuk mencapai kualitas pemotongan yang optimal dan efisiensi secara keseluruhan. Diameter tabung laser CO2 biasanya berukuran sekitar 50mm atau 80mm, yang merupakan ukuran standar untuk sebagian besar mesin ukiran.

Kabel yang Belum Terhubung

Kabel yang sudah tersambung sebelumnya dapat secara signifikan menyederhanakan proses pemasangan, mengurangi waktu dan upaya yang diperlukan untuk menyiapkan tabung laser. Fitur ini meminimalkan risiko kesalahan selama koneksi dan memastikan pengalaman penyiapan yang lebih mulus.

Kabel yang sudah tersambung sebelumnya mengurangi waktu pemasangan dan meminimalkan risiko pemasangan kabel yang salah, sehingga meningkatkan pengalaman pengguna secara keseluruhan.

Merek Teratas yang Menawarkan Laser Tabung CO2

Beberapa merek ternama dikenal dengan laser tabung CO2 berkualitas tinggi, termasuk RECI, MCWlaser, dan Ten-High. Merek-merek ini dikenal karena keandalan, kinerja, dan nilai keseluruhannya, menjadikannya pilihan populer di kalangan profesional dan penghobi. Tabung laser RECI CO2 diproduksi dengan kaca temper dan diuji pada tekanan tinggi untuk daya tahan, memastikan mereka dapat bertahan dalam aplikasi yang berat. Ribuan laser tabung CO2 dari merek-merek ini terjual setiap tahun, mencerminkan popularitas mereka dan kepercayaan yang diberikan pengguna kepada mereka.

Setiap merek menawarkan keunggulan unik, mulai dari kinerja yang konsisten hingga manufaktur berkualitas tinggi. Memahami apa yang dibawa oleh setiap merek dapat membantu Anda membuat keputusan yang tepat saat memilih laser tabung CO2 untuk kebutuhan Anda.

Perbandingan Merek

Merek-merek teratas berbeda secara signifikan dalam hal kualitas produk, kepuasan pelanggan, dan harga yang murah. Sebagai contoh, RECI dikenal karena performa dan daya tahannya yang konsisten, sehingga menjadi favorit di antara para profesional. Di sisi lain, TEN-HIGH dikenal dengan tabung laser kaca berkualitas tinggi, yang sering dinilai di antara pilihan terbaik yang tersedia.

Umpan balik pelanggan juga memainkan peran penting dalam perbandingan merek. Sementara beberapa pengguna menghadapi masalah kualitas dengan model tertentu, yang lain memuji kualitas rakitan yang kuat dan dukungan pelanggan yang sangat baik yang disediakan oleh merek seperti OM Tech. Faktor-faktor ini berkontribusi pada pengalaman kepemilikan yang positif dan mempengaruhi pilihan pelanggan.

Produk yang Direkomendasikan

Dalam hal produk yang direkomendasikan:

- Tabung laser CO2 Mssoomm 40W CO2 menonjol karena keterjangkauan dan kemampuan pemotongannya yang kuat.

- Tabung laser CO2 Bopaodao terkenal akan efisiensi dan kesesuaiannya bagi para penghobi dan profesional.

- RECI W2, dengan output daya 80W, adalah model lain yang sangat direkomendasikan, menawarkan kinerja yang sangat baik untuk aplikasi yang menuntut.

Hal lain yang patut diperhatikan adalah tabung laser MCWlaser 40W, yang dipuji karena kemudahan pemasangan dan kinerjanya yang stabil, sehingga ideal bagi pengguna pemula. Selain itu, laser K40 CO2 dihargai karena keseimbangannya antara harga dan performa, menjadikannya pilihan populer bagi mereka yang memiliki anggaran terbatas.

Kiat Pemasangan dan Pemeliharaan

Pemasangan yang tepat dan perawatan rutin sangat penting untuk kinerja dan umur panjang laser tabung CO2. Memastikan bahwa semua komponen terhubung dengan aman dan mengikuti panduan pengguna untuk penyiapan yang tepat dapat mencegah kegagalan operasional dan meningkatkan efisiensi laser. Hindari membuat asumsi yang salah tentang kemudahan pemasangan-selalu mengacu pada panduan pengguna untuk mencegah kesalahan umum.

Langkah-langkah Instalasi

Pemasangan tabung laser CO2 yang tepat sangat penting untuk mencegah masalah penyelarasan dan memastikan kinerja pemotongan yang optimal. Ikuti langkah-langkah ini:

- Lepaskan tabung yang lama.

- Potong bahan isolasi dengan hati-hati untuk mengakses sambungan kabel.

- Lepaskan tabung yang lama.

- Siapkan tabung baru dengan menyolder kabel fleksibel ke stud di setiap ujungnya untuk memfasilitasi koneksi yang aman selama pemasangan.

Setelah memposisikan tabung laser baru dalam sasis, ikuti langkah-langkah berikut ini:

- Pastikan pipa pasokan air terpasang dengan benar untuk menghindari kebocoran.

- Kencangkan tabung dengan benar pada braketnya.

- Pastikan semua sambungan untuk kabel dan tabung air dipasang dengan benar.

Langkah-langkah ini sangat penting untuk menambah bobot yang sesungguhnya demi keberhasilan pemasangan dan performa yang optimal.

Praktik-praktik Terbaik Pemeliharaan

Perawatan rutin sangat penting untuk menjaga laser tabung CO2 Anda dalam kondisi prima. Tabung laser CO2 memiliki masa pakai terbatas sekitar 1000 hingga 2000 jam dan akan membutuhkan penggantian setelah periode ini. Namun, masa pakai rata-rata tabung laser CO2 dapat berkisar antara 8.000 hingga 12.000 jam berdasarkan penggunaan, sehingga perawatan yang tepat menjadi lebih penting untuk memaksimalkan masa pakainya. Pastikan tabung laser terpasang dengan aman untuk mencegah getaran selama pengoperasian, yang dapat memengaruhi akurasi pemotongan.

Pemeriksaan rutin pada sistem pendingin juga penting untuk mencegah panas berlebih. Untuk mempertahankan performa pendinginan yang optimal dan memperpanjang masa pakai tabung laser, pertimbangkan hal berikut ini:

- Gunakan air suling dalam sistem pendingin untuk menghindari penumpukan mineral.

- Ganti air di dalam chiller setiap tiga bulan sekali.

- Periksa kebocoran pada sistem pasokan air.

Langkah-langkah ini akan membantu memastikan pendinginan yang efektif.

Memecahkan Masalah Umum

Pemecahan masalah umum pada laser tabung CO2 dapat membantu menjaga performa dan kualitasnya. Output daya yang tidak memadai adalah masalah umum yang dapat timbul dari catu daya yang tidak mencukupi atau serpihan yang menghalangi jalur optik. Memastikan pengaturan yang tepat dikonfigurasikan untuk bahan yang dipotong atau diukir dapat mengatasi masalah ini.

Masalah kualitas, seperti kedalaman ukiran yang tidak konsisten atau garis pemotongan yang tidak rata, sering kali dapat ditelusuri kembali ke lensa yang kotor atau sinar yang tidak sejajar. Perawatan rutin, termasuk membersihkan optik dan memeriksa keselarasan, sangat penting untuk menghindari masalah ini dan memastikan kinerja yang konsisten.

Umpan Balik Pelanggan tentang Laser Tabung CO2

Umpan balik pelanggan memberikan wawasan yang berharga mengenai performa dan keandalan laser tabung CO2. Banyak pengguna melaporkan tingkat kepuasan yang tinggi, dengan mengutip:

- Kemudahan penggunaan

- Kinerja yang konsisten

- Ketepatan dan kecepatan, khususnya untuk tugas pengukiran yang rumit. Aspek-aspek ini sering disorot dalam ulasan positif.

Jika Anda memiliki pertanyaan atau mengalami masalah apa pun dengan laser tabung CO2 Anda, hubungi dukungan pelanggan untuk mendapatkan bantuan.

Namun demikian, ada juga area di mana pengguna menyatakan keprihatinannya. Masalah seperti daya tahan komponen dan kerumitan rutinitas pemeliharaan adalah keluhan yang umum. Mengatasi masalah ini dapat membantu meningkatkan pengalaman dan kepuasan pengguna secara keseluruhan dengan laser tabung CO2.

Pengalaman Positif

MCWlaser sering dipuji karena layanan pelanggannya yang sangat baik, menjadikannya pilihan yang disukai oleh banyak pembeli. Pelanggan juga menyoroti keandalan tabung laser HUNST 40W CO2, mencatat kinerjanya yang konsisten dalam berbagai aplikasi. Tabung laser RECI juga dipuji karena daya tahan dan kualitas optiknya yang tinggi, membuatnya cocok untuk aplikasi profesional.

Banyak pelanggan melaporkan proyek yang berhasil diselesaikan dengan menggunakan laser CO2, mencatat kesederhanaan dalam pengoperasian dan kemampuan pengukiran yang cepat. Pengalaman positif ini menggarisbawahi nilai dan efektivitas laser tabung CO2 dalam berbagai aplikasi.

Bidang-bidang yang Perlu Ditingkatkan

Terlepas dari banyak keunggulannya, laser tabung CO2 memang memiliki area di mana perbaikan dapat dilakukan. Keluhan pengguna sering menyoroti masalah dengan kualitas dan kinerja pemotongan yang tidak konsisten. Keluhan utama lainnya melibatkan kompleksitas rutinitas pemeliharaan, yang menurut sebagian pengguna sulit untuk dikelola secara efektif.

Mengatasi masalah ini dapat secara signifikan meningkatkan pengalaman pengguna. Menyederhanakan rutinitas perawatan dan meningkatkan daya tahan komponen adalah area utama di mana produsen dapat memfokuskan upaya mereka untuk memenuhi kebutuhan pelanggan dengan lebih baik.

Ringkasan

Singkatnya, laser tabung CO2 adalah alat yang kuat dan serbaguna yang telah mengubah lanskap pemotongan dan pengukiran presisi. Memahami prinsip kerja, penggunaan umum, dan keunggulannya dapat membantu Anda membuat keputusan yang tepat tentang tabung laser mana yang harus dipilih. Fitur-fitur utama seperti catu daya, dimensi tabung, dan kabel yang sudah disambungkan memainkan peran penting dalam kinerja dan kemudahan pemasangan laser ini.

Merek-merek ternama seperti RECI, MCWlaser, dan Ten-High menawarkan produk yang andal dan berkualitas tinggi, yang memenuhi berbagai kebutuhan dan preferensi. Pemasangan yang tepat dan perawatan rutin sangat penting untuk memastikan umur panjang dan efisiensi laser ini. Dengan mempertimbangkan umpan balik pelanggan dan mengatasi masalah umum, Anda dapat meningkatkan pengalaman Anda secara keseluruhan dengan laser tabung CO2. Rangkullah kekuatan presisi dan mulailah proyek kreatif atau industri Anda berikutnya dengan percaya diri.

Pertanyaan yang Sering Diajukan

Bahan apa yang dapat dipotong dan diukir oleh laser tabung CO2?

Laser tabung CO2 mampu memotong dan mengukir bahan seperti kayu, akrilik, kaca, kulit, dan beberapa logam. Keserbagunaan ini menjadikannya pilihan populer untuk berbagai aplikasi.

Bagaimana cara kerja laser tabung CO2?

Laser tabung CO2 beroperasi dengan menggairahkan campuran gas karbon dioksida, nitrogen, dan helium secara elektrik untuk menghasilkan sinar laser yang terfokus, ideal untuk pemotongan dan pengukiran yang presisi. Metode yang efektif ini memanfaatkan sifat-sifat campuran gas untuk memberikan hasil berkinerja tinggi.

Apa saja fitur utama yang harus dicari dalam laser tabung CO2?

Apabila memilih laser tabung CO2, prioritaskan catu daya dan output, serta panjang dan diameter tabung, karena hal ini secara langsung memengaruhi performa dan pemasangannya. Pastikan adanya kabel yang sudah disambungkan untuk menambah kenyamanan dan kompatibilitas.

Apa saja merek teratas yang menawarkan laser tabung CO2?

Merek-merek teratas yang menawarkan laser tabung CO2 termasuk RECI, MCWlaser, dan Ten-High, yang dikenal karena keandalan dan kinerja berkualitas tinggi. Memilih salah satu dari merek-merek ini adalah investasi yang bijaksana untuk hasil yang optimal.

Bagaimana cara merawat laser tabung CO2 saya?

Untuk memelihara laser tabung CO2 Anda secara efektif, bersihkan lensa dan cermin secara teratur, periksa sistem pendingin, dan pastikan tabung laser terpasang dengan aman. Selain itu, ganti air pendingin dengan air suling untuk mencegah panas berlebih dan memperpanjang masa pakai tabung.