The sealed CO2 laser tube is an essential component in laser machines, directly impacting performance, beam quality, and the overall service life of the equipment. The base structure and material of the sealed CO2 laser tube are critical for ensuring compatibility with different laser machines and enhancing the tube’s durability.

Whether you are engraving wood, leather, or cutting metal, understanding the features and maintenance of a sealed CO2 laser tube will help you make an informed purchase and ensure your machine operates smoothly. The wavelength for CO2 laser tubes is typically 10.6 micrometers (10600nm), which is ideal for a wide range of applications. Feiju Laser offers a range of high-quality sealed CO2 laser tubes designed for durability and consistent output.

Introducción a la tecnología láser

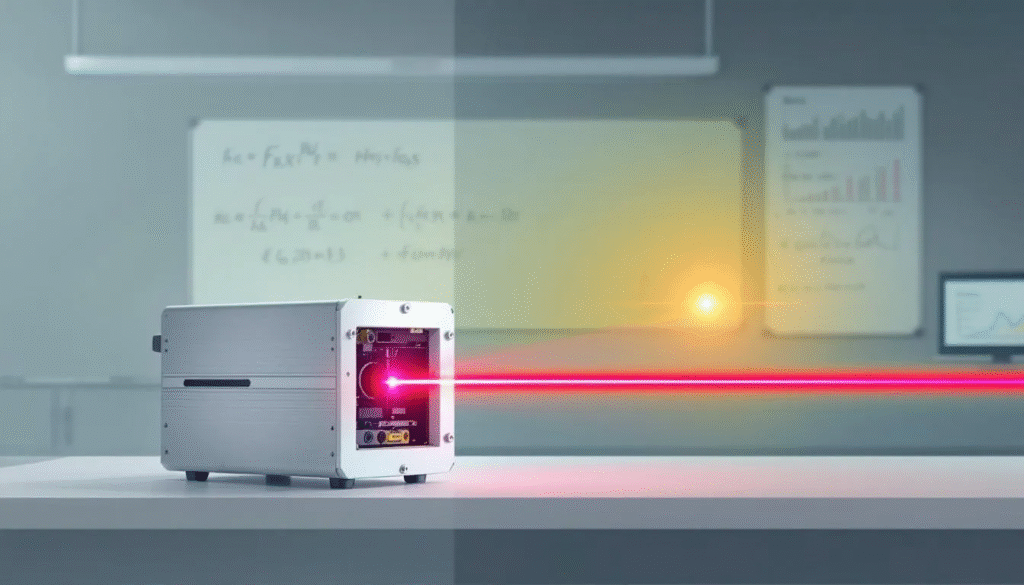

Laser technology has become a cornerstone in industries ranging from manufacturing to education, thanks to its precision and versatility. At the core of every laser machine is the laser tube, which is responsible for generating the powerful laser beam used in various applications. CO2 laser tubes, in particular, are highly valued for their ability to deliver excellent beam quality, making them a popular choice for engraving, cutting, and marking tasks.

CO2 lasers have a relatively high efficiency for gas lasers, up to 15-20%, which contributes to their widespread use. RF metal tubes offer a longer lifespan, more precise control, and are maintenance-free due to their more durable construction. The performance and service life of your laser machine depend heavily on the quality of the laser tube you choose.

To ensure optimal results, it’s important to consider factors such as the tube’s service life, the quality of cooling water, and maintaining the correct water temperature. By carefully selecting a high-quality CO2 laser tube and following recommended maintenance practices, you can maximize both the efficiency and longevity of your laser equipment.

Tipos de tubos láser

When exploring options for your laser machine, you’ll find several types of laser tubes, each designed for specific uses and materials. CO2 laser tubes are the most widely used, especially for cutting and engraving materials like wood, leather, and even thin metal. These tubes are known for their reliability and versatility in a range of applications. CO2 laser tubes are used for engraving and cutting non-metal materials like wood, leather, and acrylic. Sealed CO2 laser tubes can process a broad range of non-metallic materials, offering versatility across projects and industries.

Other types of laser tubes include excimer tubes, which are often used for precise micro-machining; Nd: YAG tubes, popular in metal processing and medical procedures; and fiber laser tubes, which excel in high-speed marking and cutting of metals. The right choice of laser tube depends on your intended use, the power requirements of your machine, and the materials you plan to work with. Consulting with a knowledgeable seller can help you select the best tube for your needs, ensuring compatibility and optimal performance for your specific application.

What is a Sealed CO2 Laser Tube?

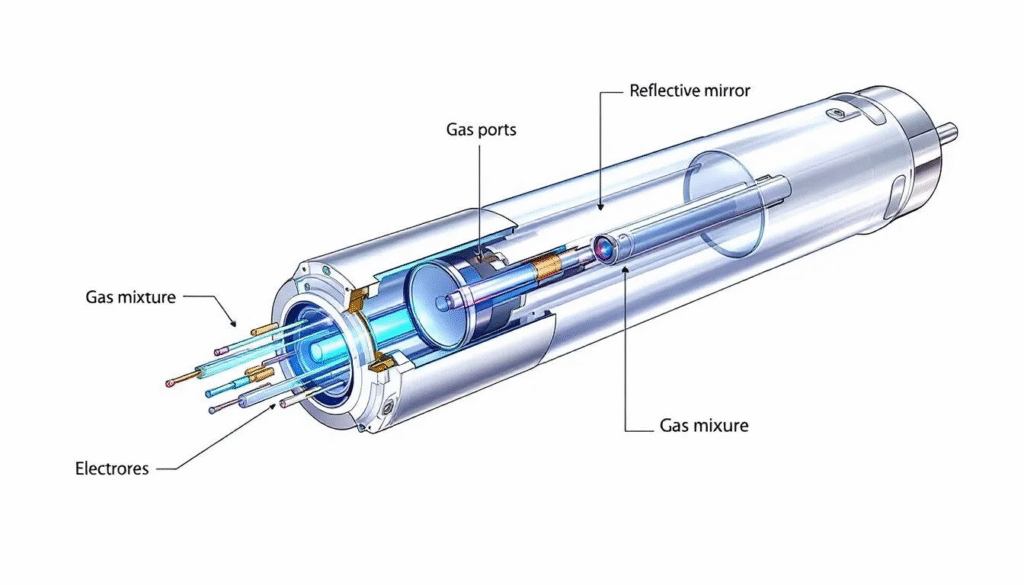

A sealed CO2 laser tube is a type of laser tube used in many laser machines. Unlike open laser tubes that require an xternal gas supply and frequent refilling, sealed tubes come pre-filled with a specific gas mixture inside a closed glass tube. The structure of a sealed CO2 laser tube usually consists of three layers: a discharge tube, a water purifying set, and a gas storage set. The components of a CO2 laser tube include a hard glass casing, a resonant cavity, and electrodes. This design helps maintain stable gas pressure and composition, which is essential for consistent laser performance.

Sealed CO2 laser tubes are created with a combination of carbon dioxide, nitrogen, and helium gases, sealed inside a glass tube with electrodes at both ends. The tube typically has positive and negative electrodes that connect to the machine’s power supply. A sealed CO2 laser tube uses a DC voltage to excite the gas mixture and produce photons. Sealed CO2 laser tubes differ from RF metal tubes primarily in construction and excitation method. When energized, the gas inside the tube produces a laser beam used for engraving or cutting various materials.

The middle section of the tube, which includes the discharge tube and resonant cavity, plays a critical role in the internal configuration and stability of the laser. Key optical elements such as the lens, along with mirrors and electrodes, are essential in the tube’s construction and directly impact the laser’s performance and longevity.

Learn more about the basics of CO2 laser tubes on Mundo Laser Focus.

Advantages of Using a Sealed CO2 Laser Tube

One of the most significant benefits of sealed CO2 laser tubes is their ease of use and low maintenance requirements. Since the gas is sealed inside, users do not need to worry about refilling or adjusting the gas mixture, which can be a problem with open tubes. Sealed CO2 glass tubes are generally less expensive and more common in entry-level machines. However, sealed CO2 glass tubes have a shorter lifespan compared to RF tubes and may require periodic gas refills. This feature makes sealed tubes ideal for users who want a reliable laser tube that can be installed quickly and used immediately.

Service life is another advantage. A well-maintained sealed CO2 laser tube can last thousands of hours, providing stable beam quality throughout its lifespan. The service life of a 60W CO2 laser tube is generally around 1500 hours, while some high-quality tubes can last over 2500 hours. The sealed design helps prevent contamination and gas leakage, which are common issues that affect the life and performance of laser tubes.

Additionally, sealed tubes are less sensitive to fluctuations in water temperature and cooling water quality. Proper cooling is essential because the laser tube generates significant heat during operation. Using clean cooling water and maintaining the recommended water temperature ensures the tube does not overheat, preventing damage and maintaining stable laser output.

However, sealed CO2 glass tubes are more sensitive to temperature changes and humidity, which can impact their performance if not properly managed. It is important to regularly check that the water cycle and cooling water temperature remain within normal ranges to ensure stable operation. Keeping the laser tube close to optimal operating conditions requires close monitoring of water temperature, water flow, and ensuring the tube is properly positioned and maintained.

For detailed maintenance tips, visit RP Photonics Encyclopedia.

Key Features to Consider When Choosing a Sealed CO2 Laser Tube

When purchasing a sealed CO2 laser tube, there are several important factors to keep in mind to ensure you get the right product for your laser machine. It is essential to consider the size (length and diameter) of the laser tube, as this affects compatibility with your specific machine and the intended application.

Different sealed CO2 laser tubes are designed to meet the needs of various market segments, from industrial to artisanal users.

Power and Length

The power rating of the laser tube, measured in watts, directly affects the cutting and engraving speed and the types of materials you can work with. Common power ratings range from 40W to 150W or more. CO2 laser tubes come in various power ratings, including 20W to 180W. Higher power tubes can cut thicker materials like metal, while lower power tubes are suitable for engraving wood, leather, and plastic.

The length of the tube is also crucial. It must match the design specifications of your laser machine. Incorrect tube length can lead to alignment problems, unstable beam quality, and reduced efficiency.

Beam Quality and Stability

Beam quality is essential for precision engraving and cutting. A sealed CO2 laser tube should produce a stable, focused beam with minimal divergence. This ensures clean cuts and detailed engraving results. When buying from a reputable seller or shop, check if the tubes are tested for beam quality and stability before shipping.

Cooling System Compatibility

Since sealed CO2 laser tubes require efficient cooling, ensure your machine’s cooling water system is compatible. The water outlet and inlet should be properly connected to avoid bubbles inside the tube, as bubbles can negatively affect beam quality and may damage the tube over time.

Quality and Brand Reputation

Choosing a high-quality product from a trusted brand or seller can save you money and time in the long run. Feiju Laser is known for its reliable sealed CO2 laser tubes with excellent beam quality and long service life. Look for reviews and customer feedback to find laser tubes that have a proven track record for durability and performance.

Reading customer reviews and checking star ratings is important to assess the product’s reputation and trustworthiness. Customers often share their experiences with the product, which can help inform your decision. Some customers have found lower prices elsewhere, so it’s worth comparing offers before making a purchase. Some sellers offer insurance or warranty options, adding an extra layer of confidence to your purchase.

Aplicaciones del láser de CO2

CO2 laser tubes are renowned for their versatility and are widely used in a variety of laser machines. In the world of manufacturing and design, these tubes power laser cutting machines that can slice through wood, leather, plastic, and even some metals with precision and speed. Sealed CO2 laser tubes can also engrave certain metals, such as stainless steel and aluminum, expanding their range of applications.

CO2 laser tubes are also the go-to choice for engraving machines, allowing users to create detailed designs and patterns on materials such as wood, metal, and stone. Additionally, CO2 lasers are frequently used in marking machines to apply permanent marks like serial numbers, logos, and barcodes to products. The superior beam quality produced by CO2 laser tubes ensures clean, accurate results, making them a preferred option for both industrial and creative applications.

Precauciones y directrices de seguridad

Working with laser tubes requires strict adherence to safety precautions to protect both users and equipment. CO2 laser tubes are classified as Class 4 lasers, indicating they require special safety precautions during usage. Always wear appropriate protective gear, such as safety glasses and gloves, when handling or operating a laser machine. Before starting, ensure the laser tube is properly installed and that the cooling water system is functioning efficiently.

Regularly check the water temperature and make adjustments as needed to prevent the tube from overheating, which can lead to damage or reduced service life. Follow the manufacturer’s maintenance instructions closely, and inspect the tube and machine for any signs of wear or issues. If you encounter any problems or are unsure about maintenance procedures, contact the seller or manufacturer for guidance. Taking these steps will help ensure safe operation and extend the life of your laser tube.

Installation and Maintenance Tips for Sealed CO2 Laser Tubes

Proper installation is vital to ensure your sealed CO2 laser tube performs optimally. Always handle the tube carefully to avoid damage during installation. Make sure the tube is installed in the correct place within the machine, and that all connections, such as the water inlet and outlet, are properly secured. Connect the tube securely to the machine’s power supply, ensuring the positive and negative terminals are correctly matched.

Regular maintenance includes checking the cooling water quality and temperature. Use distilled or purified water to prevent mineral buildup inside the tube. Maintain the recommended water temperature to avoid overheating, which can shorten the tube’s service life.

Inspect the tube periodically for any signs of damage or bubbles inside the glass. If you notice any abnormalities, contact the seller or a professional technician immediately to prevent further problems.

Common Problems and How to Avoid Them

Some common issues with sealed CO2 laser tubes include unstable beam quality, reduced power output, and premature tube failure. These problems often stem from improper cooling, incorrect installation, or using low-quality tubes.

When properly maintained, sealed CO2 laser tubes offer great performance and durability.

To avoid these issues, always purchase your sealed CO2 laser tube from a reputable shop that tests its products before shipping. Purchased tubes are tested to ensure they deliver the specified power and quality. Follow the manufacturer’s guidelines for installation and maintenance. Keep the cooling water clean and at the recommended temperature, and avoid sudden power surges when operating the machine.

Replacement and Disposal

Over time, even the best laser tubes will reach the end of their service life or may become damaged and require replacement. When it’s time to replace your laser tube, make sure the new tube is fully compatible with your laser machine and follow the manufacturer’s installation guidelines to avoid any issues. Proper disposal of old laser tubes is important, as they may contain materials that require special handling. Check local regulations for hazardous waste disposal, and consider using manufacturer recycling programs if available.

Regular maintenance and careful use can help extend the life of your laser tube, reducing the frequency of replacements and saving you money in the long run. By ensuring proper replacement and disposal, you help protect both your investment and the environment.

Where to Buy Sealed CO2 Laser Tubes

Finding a reliable seller or shop for sealed CO2 laser tubes is essential for getting a quality product. Many sellers operate online, offering a wide range of tubes with different power ratings and sizes. When choosing a seller, consider their reputation, customer reviews, and after-sales support.

Many online sellers also feature an ‘Add to Cart’ button, allowing for convenient and quick purchasing directly from the product listing.

If you are based in the Netherlands or nearby regions, look for local suppliers who can ship the item quickly and provide easier access to support and warranty services. Always check if the seller offers tested and insured products to ensure you receive a working laser tube.

For trusted suppliers and more buying tips, see Laser Engraving Tips.

Conclusion: Sealed CO2 Laser Tube Summary and Key Takeaways

A sealed CO2 laser tube is a vital component for laser machines, offering advantages like low maintenance, stable beam quality, and long service life. Sealed CO2 laser tubes are considered ‘fit and forget’ components that do not require complex maintenance. By choosing the right power, length, and quality, and ensuring proper installation and maintenance, you can maximize the performance of your laser machine for engraving and cutting various materials such as wood, leather, and metal.

When purchasing a sealed CO2 laser tube, take the time to find a reputable seller and verify product quality through reviews and testing. Proper care, including maintaining cooling water and water temperature, will help prevent damage and extend the life of your laser tube, ensuring your machine operates efficiently for years to come. If you have any questions or need assistance, don’t hesitate to contact Feiju Laser or a professional technician to get the most out of your purchase.