¿Necesita una herramienta eficaz para grabar y cortar múltiples materiales? El láser CO2 de 100 W ofrece un alto rendimiento y precisión. Esta guía explora las principales características, especificaciones y ventajas de este producto. Descubra cómo un láser CO2 de 100W puede mejorar sus proyectos con su potencia y versatilidad.

Principales conclusiones

- Un tubo láser de CO2 de 100 W funciona eficazmente en diversos materiales, ofrece una vida útil de unas 10.000 horas y es ideal tanto para aplicaciones de grabado como de corte.

- Una instalación adecuada y un mantenimiento regular, incluidas la limpieza y la inspección, son cruciales para mejorar el rendimiento y la longevidad del tubo láser.

- Invertir en un tubo láser de CO2 de 100 W proporciona ventajas rentables a las empresas, ya que permite una producción de alta velocidad con precisión al tiempo que ofrece precios competitivos y opciones de garantía.

Tubos láser de CO2 de 100 W

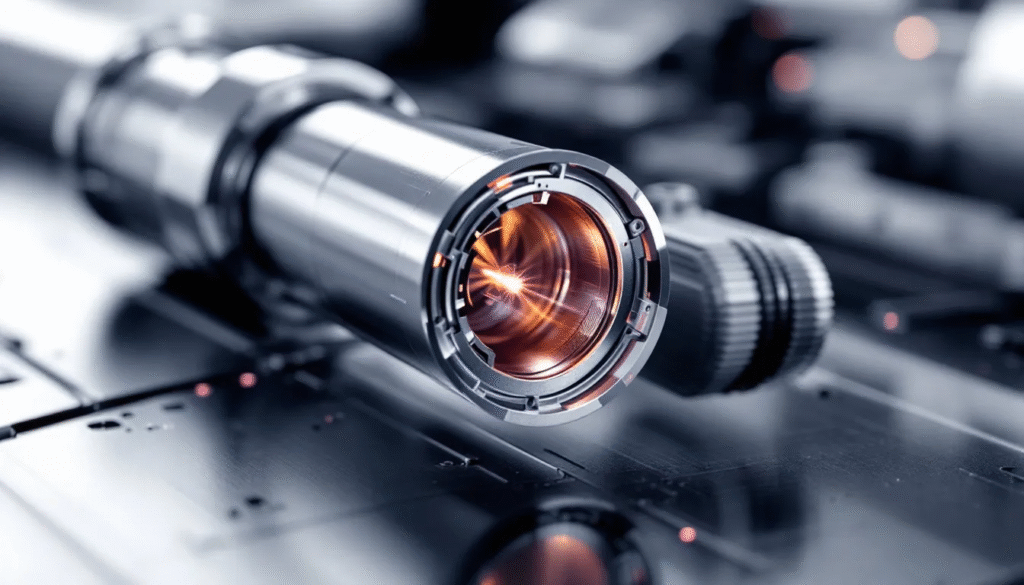

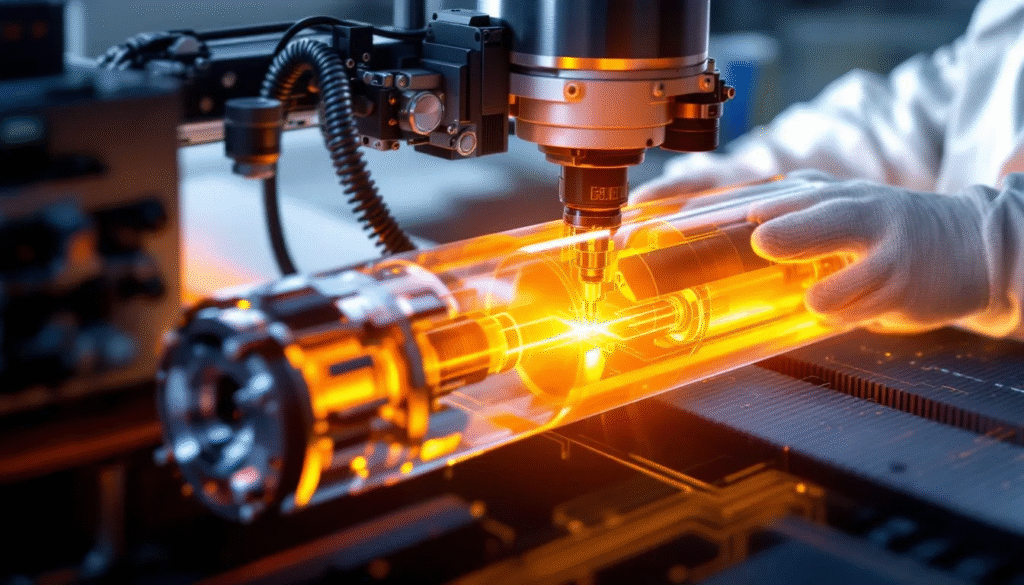

A Tubo láser de CO2 de 100 W es una potente herramienta conocida por su versatilidad en el grabado y el corte. Las características clave incluyen:

- Capacidad para cortar y grabar con eficacia diversos materiales, como madera, acrílico y cuero.

- Funcionamiento típico a una longitud de onda de 10,6 micras, emitiendo un haz láser focalizado ideal para trabajos detallados.

- Dimensiones específicas, con una longitud típica de 1450 mm y un diámetro exterior de 80 mm.

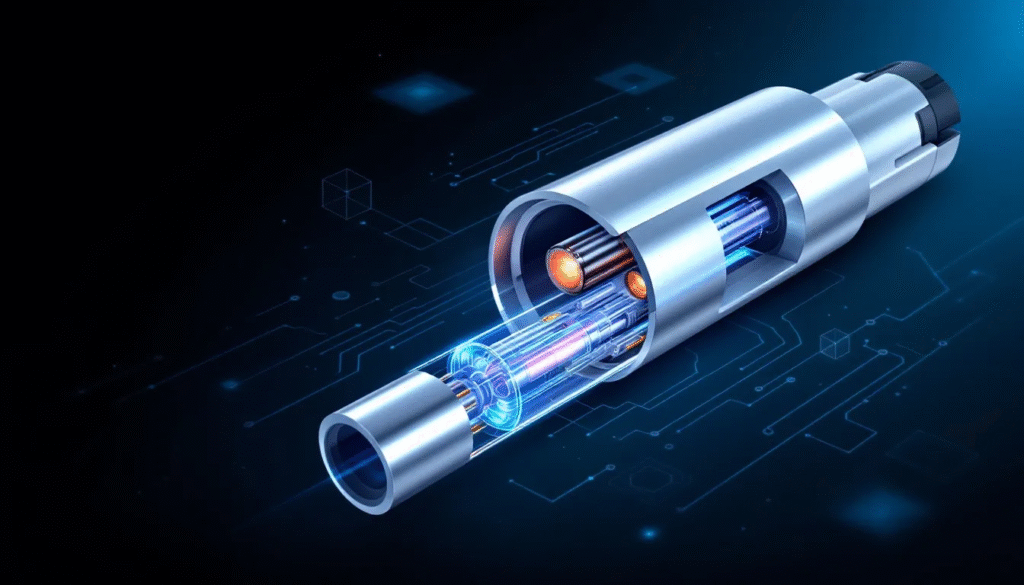

La vida útil de un tubo láser de CO2 de 100W es de aproximadamente 10.000 horas, lo que garantiza un uso a largo plazo y reduce la frecuencia de las sustituciones. La fuente de alimentación láser, el cabezal láser y otros componentes están diseñados para funcionar a la perfección con el tubo láser, proporcionando un haz estable y potente para diversas aplicaciones. Sin embargo, la vida útil prevista puede variar, con una media de 8.000 horas de funcionamiento en función de los ajustes de potencia. El funcionamiento del tubo a la potencia óptima (40-70%) suele dar como resultado una vida útil de 5.000-6.500 horas, mientras que un uso a mayor potencia (70-100%) puede reducir la vida útil a 3.000-4.000 horas.

Comprender estos fundamentos puede mejorar significativamente la eficacia y la vida útil de su grabadora o cortadora láser. Para entrar en este campo con eficacia, es crucial comprender estos fundamentos. Por ejemplo, la humedad permitida para el tubo láser de CO2 de 100W es inferior a 85%, que es una condición ambiental importante que debe mantenerse para un rendimiento y una longevidad óptimos. El funcionamiento del tubo láser de CO2 de 100W a la potencia mínima (10-40%) puede proporcionar una vida útil de 7.000-8.000 horas.

Especificaciones

Conociendo las especificaciones de un 100W Tubo láser de CO2 es importante a la hora de considerar una compra. La corriente de funcionamiento recomendada para estos tubos oscila entre 6 y 24 mA, lo que garantiza una potencia de salida constante de al menos 100 W. La vida media de estos tubos es de entre 10.000 y 12.000 horas en condiciones óptimas, lo que contribuye a su durabilidad y fiabilidad. Estas especificaciones las convierten en un gran valor tanto para uso profesional como para aficionados.

En términos de características físicas, un tubo láser de CO2 de 100 W suele medir unos 1.000 mm de longitud y pesar entre 4 y 5 kg. Es importante tener en cuenta estas dimensiones durante el proceso de instalación para garantizar un ajuste y alineación adecuados dentro de su máquina. Además, el tubo láser de CO2 de 100 W tiene una longitud de 1450 mm, una especificación fundamental para garantizar la compatibilidad con su configuración. El uso de materiales y técnicas de construcción de alta calidad mejora aún más el rendimiento y la vida útil de estos tubos. Además, el tubo pesa aproximadamente 20 kg, un factor a tener en cuenta durante su manipulación e instalación.

Materiales

Los materiales de construcción de un tubo láser de CO2 de 100W desempeñan un papel importante en su rendimiento y longevidad. Estos tubos suelen estar fabricados con vidrio de borosilicato, conocido por su durabilidad y resistencia térmica. Este tipo de vidrio mejora la resistencia del tubo al choque térmico, garantizando un rendimiento constante a lo largo del tiempo. Además, el tubo láser de CO2 de 100W está hecho de vidrio de borosilicato, cobre y plástico, que contribuyen a su durabilidad y eficiencia. El cabezal metálico del tubo láser de CO2 de 100W está diseñado para evitar el agrietamiento y garantizar la estabilidad.

Los materiales de alta calidad utilizados en la fabricación mejoran la eficacia general y la durabilidad de estos tubos de contenido.

Proceso de instalación

La instalación correcta de un tubo láser de CO2 de 100 W es crucial para un rendimiento y una longevidad óptimos. Utilizando guías visuales, como Tutoriales de instalación en YouTubepuede simplificar enormemente el proceso de instalación y aumentar la confianza del usuario. Seguir las mejores prácticas durante la instalación ayuda a evitar problemas y prolonga la vida útil del tubo láser.

Una configuración limpia y ordenada puede ayudar a evitar errores y mejorar la eficiencia de su cortadora o grabadora láser.

Características y ventajas de los tubos láser de CO2 de 100 W

El tubo láser de CO2 de 100 W está repleto de características y ventajas que lo convierten en la mejor elección para aplicaciones de grabado y corte. Gracias a su avanzada tecnología, estos tubos ofrecen una vida útil más larga y una mayor estabilidad. Son conocidos por su capacidad para producir rayos láser estables y potentes, lo que los hace adecuados para una gran variedad de tareas. Un mantenimiento regular es clave para maximizar la eficacia y la vida útil de su tubo láser de CO2 de 100W.

Industrias como la de alimentación y bebidas utilizan láseres de CO2 de 100 W para codificar y marcar a alta velocidad, garantizando etiquetas claras que ayudan a rastrear los productos. Además, estos láseres son especialmente eficaces para crear señalización personalizada y expositores acrílicos, ya que permiten una alta precisión y una producción rápida.

La versatilidad y fiabilidad de los tubos láser de CO2 de 100 W los convierten en un valioso activo en diversos sectores, como el textil, la automoción, la artesanía y la porcelana.

Rendimiento mejorado

Lentes de alta calidad en tubos láser de CO2 de 100 W:

- Un índice de transmisión de luz superior a 98% aumenta significativamente la eficacia.

- Cristal de alta calidad que mejora la transmisión de la luz láser, lo que da como resultado cortes detallados y limpios en materiales como madera, acrílico y cristal.

- Eficacia en el grabado de diseños intrincados en materiales como el vidrio y la madera, proporcionando resultados de gran calidad y detalle.

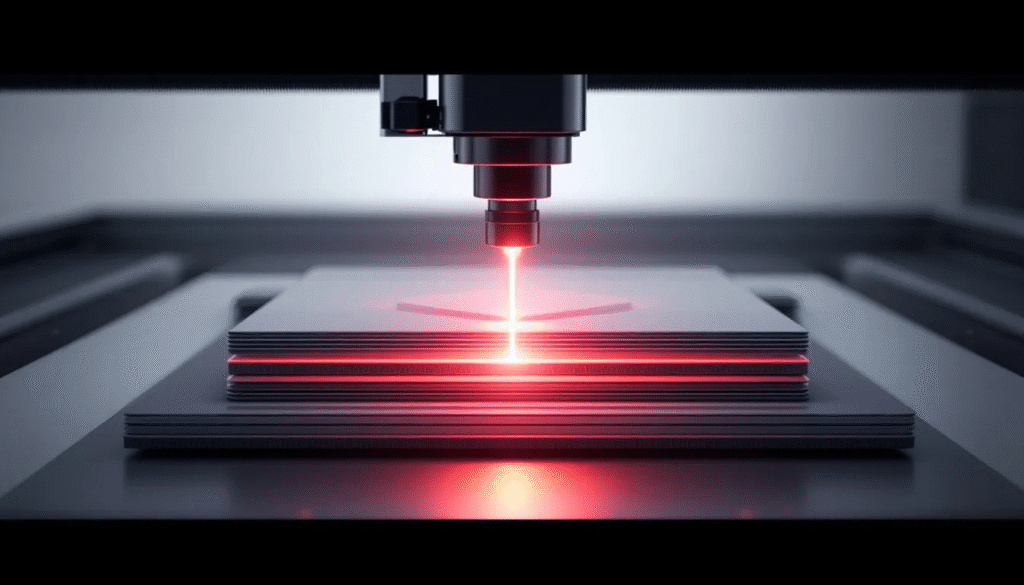

Una cortadora láser de CO2 de 100 W puede:

- Corta fácilmente materiales como madera y acrílico, alcanzando espesores de hasta 12 mm.

- Corta diversos materiales, incluidos plásticos y metales.

- Ofrecen bordes limpios, reduciendo la necesidad de procesos de acabado secundarios.

La robusta construcción y los sistemas de refrigeración de estos láseres aumentan su vida útil y su seguridad de funcionamiento. El tubo del láser de CO2 de 100 W cuenta con un cierre hermético que ofrece una disipación térmica superior.

Durabilidad y seguridad

Construidos a partir de vidrio de borosilicato, los tubos láser de CO2 de 100 W están diseñados para soportar altas presiones y temperaturas, garantizando un uso prolongado. El uso de electrodos metálicos mejora su durabilidad y rendimiento general. Las inspecciones rutinarias deben centrarse en el tubo para detectar cualquier signo de grietas o fugas que puedan poner en peligro el rendimiento del agua.

Es importante comprobar si los espejos y la lente de enfoque presentan picaduras o arañazos, ya que incluso los daños menores pueden requerir su sustitución. Realizar una inspección visual del tubo láser puede ayudar a identificar grietas o marcas de quemaduras que requieran sustitución. Estas inspecciones evitan daños mayores y garantizan la seguridad operativa. Las lentes de salida contaminadas pueden limpiarse con alcohol anhidro para mantener un rendimiento óptimo. El uso de espejos reflectantes en los ángulos correctos es crucial para mantener un haz paralelo.

Un mantenimiento regular y una manipulación adecuada pueden prolongar considerablemente la vida útil de su tubo láser de CO2 de 100 W, garantizando que siga siendo una herramienta fiable y segura para sus proyectos.

Relación coste-eficacia

Invertir en un tubo láser de CO2 de 100 W puede resultar económico para las pequeñas empresas porque:

- Elimina la necesidad de disponer de varias máquinas para manipular distintos materiales.

- Estos tubos proporcionan una mayor eficacia de corte gracias a una mejor concentración de energía.

- Ofrecen un valor significativo dados sus precios competitivos.

Aunque ofrecen un alto rendimiento, los tubos láser de CO2 de 100 W siguen siendo asequibles en comparación con otras opciones de tubos láser del mercado. Su rentabilidad es evidente, equilibrando eficiencia, valor financiero y precio competitivo. Además, se proporciona una garantía de 1 año para los tubos láser de CO2 de 100W, ofreciendo tranquilidad y apoyo a los compradores en caso de defectos de fabricación o problemas.

Aplicaciones de los láseres de CO2 de 100 W

La versatilidad de los láseres de CO2 de 100 W los convierte en la opción preferida para diversas aplicaciones. Estos tubos láser son conocidos por:

- Alta precisión

- Capacidad para trabajar con diversos materiales, como madera, vidrio y metal.

- Capacidad para producir un haz enfocado que permite realizar tareas de grabado y corte intrincadas, lo que las hace adecuadas para trabajos detallados.

Los clientes mencionan con frecuencia la eficacia de los tubos láser de CO2 de 100 W para diversas aplicaciones, lo que se traduce en altos índices de satisfacción.

Varios revisiones de vídeo destacan las aplicaciones reales y las experiencias de los usuarios, proporcionando información práctica sobre la eficacia de los tubos láser de CO2 de 100 W. Desde la creación de rótulos personalizados hasta intrincados diseños sobre madera y acrílico, estos láseres ofrecen un amplio abanico de posibilidades. La gran precisión y rendimiento de los tubos láser de CO2 de 100 W los convierten en una herramienta inestimable tanto en proyectos industriales como personales.

Grabado

Estos tubos láser funcionan en modo TEM00, que proporciona un diámetro de punto de haz enfocado de 0,16-0,24 pulgadas, mejorando el detalle y la precisión en el grabado. La tecnología del modo TEM00 mejora la estabilidad y precisión del haz, dando como resultado cortes más detallados y limpios. Ajustar la configuración de potencia en función del material que se esté procesando puede influir significativamente tanto en la calidad del corte o grabado como en la longevidad del tubo láser.

Además del grabado y el corte, los láseres de CO2 de 100 W se utilizan para aplicaciones de marcado, proporcionando códigos duraderos en los productos para evitar falsificaciones. Muchos usuarios afirman que la velocidad de corte y la precisión de los tubos láser de CO2 de 100 W han mejorado notablemente su eficiencia de producción.

Estas capacidades hacen del láser de CO2 de 100 W una herramienta ideal para grabar diseños intrincados en diversos materiales.

Corte

El nivel de potencia de 100 W ofrece varias ventajas:

- Permite velocidades de corte más rápidas

- Permite manipular materiales más gruesos en comparación con láseres de menor potencia

- Trabaja eficazmente con diversos materiales

- Garantiza resultados de grabado y corte de alta calidad

Además de para grabar y cortar, los láseres de CO2 de 100 W también se utilizan para marcar y grabar en metales blandos y recubiertos. Muchos usuarios informan de resultados de grabado y corte satisfactorios, y aprecian la precisión y el detalle que se pueden conseguir con los tubos láser de CO2 de 100 W.

Otros usos

Además de para grabar y cortar, los láseres de CO2 de 100 W también se emplean para marcar, grabar e incluso crear diseños en 3D en diversos materiales. Estos láseres pueden grabar una amplia gama de materiales, como madera, acrílico, vidrio y metal, permitiendo diseños detallados y patrones intrincados.

La versatilidad de los láseres de CO2 de 100 W en diversas aplicaciones demuestra su valor para proyectos creativos tanto industriales como personales.

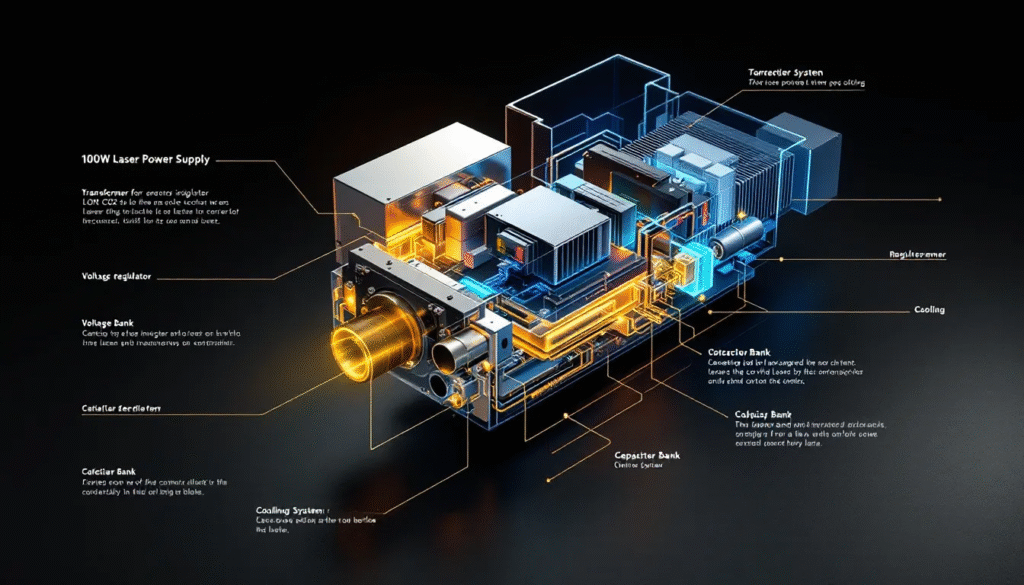

Elección de la fuente de alimentación adecuada para su láser de CO2 de 100 W

Seleccionar la fuente de alimentación correcta es vital para conseguir un rendimiento óptimo en un láser de CO2 de 100W. La fuente de alimentación del láser debe coincidir con los requisitos de voltaje y corriente del tubo de láser de CO2 específico para garantizar un funcionamiento correcto. Esto garantiza que el láser funcione eficazmente y que se maximice la longevidad del tubo láser. La actualización de un tubo láser de 50W a 100W requiere la sustitución de la fuente de alimentación láser y el enfriador de agua.

Es importante alinear correctamente el tubo láser durante la instalación para evitar problemas de enfoque y precisión del haz. Muchas fuentes de alimentación pueden funcionar con tubos láser de distintos fabricantes, siempre que tengan una potencia nominal similar. Garantizar la compatibilidad y la correcta instalación evita problemas de funcionamiento y maximiza la eficacia de la configuración del láser. El uso de un tubo de mayor diámetro puede provocar problemas de compatibilidad con los soportes y espejos existentes.

Compatibilidad

Los valores nominales de tensión y corriente de la fuente de alimentación deben coincidir con las especificaciones del tubo láser para garantizar un funcionamiento correcto. Las fuentes de alimentación deben coincidir con los requisitos de tensión y corriente del tubo láser de CO2 específico para un funcionamiento óptimo. Esta compatibilidad es crucial para mantener la eficacia y longevidad del tubo láser.

Es importante alinear correctamente el tubo láser durante la instalación para evitar problemas de enfoque y precisión del haz. Muchas fuentes de alimentación pueden funcionar con tubos láser de distintos fabricantes, siempre que tengan una potencia nominal similar. Garantizar la compatibilidad y la instalación correcta evita problemas de funcionamiento y maximiza la eficacia de la configuración del láser.

Ajustes de potencia

Los ajustes de potencia correctos son esenciales para garantizar la longevidad de su tubo láser. Un ajuste adecuado de la potencia puede prolongar significativamente la vida útil del tubo láser al evitar el sobrecalentamiento.

Ajustar la potencia correctamente es vital, ya que influye en gran medida en la longevidad del tubo láser. Asegurarse de que la configuración de potencia está correctamente ajustada ayudará a mantener el rendimiento y la eficiencia de su tubo láser.

Consejos de instalación

Los tubos láser de CO2 de 100 W suelen venir con cables preconectados para simplificar el proceso de instalación. Cada punto de conexión de una fuente de alimentación debe estar claramente etiquetado para facilitar una instalación rápida y correcta. Es esencial montar firmemente el tubo láser para minimizar las vibraciones durante el funcionamiento.

Siga estos consejos de instalación para garantizar un proceso de instalación eficiente y sin problemas.

Consejos de mantenimiento para tubos láser de CO2 de 100 W

Un mantenimiento adecuado es esencial para que su tubo láser de CO2 de 100 W rinda al máximo. Con una vida útil de aproximadamente 10.000 horas, estos tubos láser ofrecen un valor sustancial, reduciendo la frecuencia de las sustituciones y los costes de mantenimiento. Las prácticas de mantenimiento regulares, como la limpieza, la comprobación de daños y el almacenamiento adecuado, pueden prolongar significativamente la vida útil de su cortadora o grabadora láser. Además, debe comprobarse que el sistema de refrigeración circula correctamente para evitar el sobrecalentamiento, que puede afectar gravemente al rendimiento y la longevidad del tubo.

Las prácticas clave para la configuración y el mantenimiento del tubo láser incluyen:

- Conectar la fuente de alimentación al tubo láser de forma limpia y ordenada ayuda a evitar cortocircuitos y garantiza la seguridad.

- Conecte correctamente a tierra los componentes eléctricos para evitar interferencias y posibles daños en el tubo láser.

- Realización de rutinas de mantenimiento para identificar las necesidades críticas de limpieza y prolongar la vida útil de los equipos.

Para construir tu propia cortadora láser de CO2, necesitas componentes como un tubo láser, una fuente de alimentación, espejos, soportes para espejos, una lente de enfoque y un cabezal láser.

- Conectar la fuente de alimentación al tubo láser de forma limpia y ordenada ayuda a evitar cortocircuitos y garantiza la seguridad.

- Conecte correctamente a tierra los componentes eléctricos para evitar interferencias y posibles daños en el tubo láser.

- Realización de rutinas de mantenimiento para identificar las necesidades críticas de limpieza y prolongar la vida útil de los equipos.

Limpieza regular

La limpieza periódica es necesaria para mantener el rendimiento óptimo y la longevidad del tubo láser y los espejos. El polvo y los residuos acumulados pueden reducir la eficacia del corte y el grabado. Utilizar los limpiadores y herramientas adecuados es vital para proteger las superficies sensibles de los espejos durante la limpieza.

Las rutinas de mantenimiento ayudan a identificar las necesidades críticas de limpieza, alargando la vida útil de los equipos.

Comprobación de daños

Inspeccionar el tubo láser en busca de daños es una parte crucial del mantenimiento. Los puntos clave que hay que comprobar son:

- Una lectura del amperímetro inferior a 10 m indica que la fuente de alimentación del láser puede estar dañada.

- Inspección periódica para detectar grietas.

- Comprobando si hay marcas de quemaduras.

- Buscar otros tipos de daños. Estos pasos pueden evitar graves problemas de funcionamiento y garantizar la fiabilidad del producto.

Identificar los daños a tiempo y tratarlos con prontitud ayudará a mantener el rendimiento y la seguridad de su tubo láser de CO2 de 100W.

Almacenamiento adecuado

Almacenar el tubo láser adecuadamente ayuda a prolongar su vida útil. Almacenar el tubo en un lugar fresco y seco evitará que se dañe por factores ambientales. Asegurarse de que el tubo está bien guardado y protegido de daños físicos es esencial para mantener su rendimiento y longevidad.

Unas prácticas de almacenamiento adecuadas preservan la eficacia del tubo láser y su preparación para un uso futuro.

Información sobre compras y envíos

Cuando se trata de comprar un tubo láser de CO2 de 100W, múltiples proveedores ofrecen varias opciones, incluyendo tanto vendedores en línea como locales. Los clientes pueden esperar precios transparentes con tarifas justas para estos tubos láser. Comprender el proceso de compra y qué buscar en términos de precio, garantía y envío puede ayudarle a tomar una decisión informada.

Los plazos de envío de los tubos láser de CO2 de 100 W varían de unos días a un par de semanas, dependiendo del proveedor y del método de envío seleccionado. Muchos vendedores proporcionan información de seguimiento para controlar la entrega de los tubos láser.

Es importante inspeccionar el paquete en el momento de la entrega e informar de cualquier daño en un plazo de tres días. Conocer estos detalles puede ayudar a garantizar una experiencia de compra y envío sin problemas.

Desglose de precios

El coste estándar de un tubo láser de CO2 de 100 W es de aproximadamente $700, con posibles descuentos que reducen el precio a alrededor de $680. Los precios pueden variar significativamente en función de la marca, la calidad y las características adicionales, con posibles descuentos disponibles para compras al por mayor. Los descuentos suelen rondar los 3% durante las promociones.

Teniendo en cuenta el precio estándar y los descuentos potenciales, los compradores pueden optar por comprar y tomar decisiones informadas para maximizar su inversión en tubos láser de CO2 de 100W que han adquirido.

Garantía y certificaciones

Las opciones de garantía para los tubos láser de CO2 de 100W varían, y muchos vendedores ofrecen servicios de garantía como parte de sus opciones de compra. La mayoría de los tubos láser de CO2 de 100 W vienen con un periodo de garantía que oscila entre 6 y 12 meses, que cubre los defectos de fabricación y ofrece reparaciones o sustituciones en condiciones específicas.

Certificaciones como FDA y CE pueden aplicarse a estos tubos láser, indicando el cumplimiento de las normas de seguridad y medioambientales. Asegurarse de que su compra viene con una garantía y certificaciones puede proporcionar tranquilidad adicional.

Detalles de envío

Los gastos de envío de los tubos láser de CO2 de 100W se determinan en el momento de la compra y pueden variar en función de la ubicación. Los plazos de entrega pueden oscilar entre 3 y 15 días laborables, dependiendo del método de envío seleccionado y de la ubicación del comprador. Muchos vendedores proporcionan información de seguimiento para controlar la entrega de los tubos láser.

Los clientes deben inspeccionar la caja en el momento de la entrega e informar de cualquier daño o ponerse en contacto con nosotros en un plazo de tres días para asegurarse de que cualquier problema se soluciona rápidamente.

Opiniones y comentarios de los clientes

Las opiniones y comentarios de los clientes proporcionan información valiosa sobre el rendimiento y la fiabilidad de los tubos láser de CO2 de 100 W. Entre los puntos clave sobre garantías y certificaciones se incluyen:

- Muchos fabricantes ofrecen garantías de hasta 16 meses, lo que garantiza la asistencia al cliente y la fiabilidad del producto.

- La mayoría de los fabricantes de renombre ofrecen garantías para los tubos láser de 100 W.

- Muchos productos cumplen las certificaciones de la FDA y la CE, lo que garantiza su seguridad y calidad.

- Estas garantías reflejan el compromiso con la satisfacción del cliente y la calidad del producto, algo esencial en el mercado de los equipos láser.

Los comentarios destacan el aprecio de los usuarios por el rendimiento constante y la fiabilidad del láser de CO2 de 100 W, lo que refuerza su confianza en el producto. Muchos usuarios afirman que la durabilidad del tubo láser de CO2 de 100 W superó sus expectativas, lo que se traduce en opiniones positivas.

Otro usuario destacó la alta calidad de los cortes conseguida, que mejoró ampliamente su flujo de trabajo de producción gracias a las actualizaciones para añadir mayor eficacia y cambio. Se mostraron satisfechos con los resultados.

Experiencias positivas

Los clientes se han mostrado muy satisfechos con la facilidad de uso del tubo láser de CO2 de 100 W, apreciando su sencillo funcionamiento. Un cliente compartió su éxito en el lanzamiento de un pequeño negocio de grabado, atribuyendo su crecimiento a la eficiencia del láser de CO2 de 100W.

Los comentarios destacan el aprecio de los usuarios por el rendimiento y la fiabilidad constantes del láser de CO2 de 100 W, lo que refuerza su confianza en el producto.

Problemas comunes

Pueden surgir problemas de garantía comunes si el tubo láser no cumple las normas de rendimiento especificadas, por lo que es importante comprobar las garantías y certificaciones antes de comprarlo. La limpieza periódica de la lente y los espejos es vital para mantener una calidad óptima de corte y grabado, ya que la suciedad puede reducir significativamente el rendimiento.

Ajustar la potencia de salida correcta y garantizar la compatibilidad con la fuente de alimentación son pasos cruciales para evitar posibles problemas de funcionamiento. El almacenamiento adecuado del tubo láser cuando no se utiliza puede evitar daños y prolongar considerablemente su vida útil.

Comentarios en vídeo

Los comentarios en vídeo proporcionan información sustancial sobre la eficacia y el rendimiento de los tubos láser de CO2 de 100 W. Los usuarios elogian con frecuencia los resultados de grabado de alta calidad obtenidos con estos tubos, citando la claridad y la precisión. Algunos clientes informan de problemas con la configuración inicial y la calibración, lo que sugiere que unas guías de instalación más claras serían beneficiosas.

Ver reseñas en vídeo puede ayudar a los compradores potenciales a explorar aplicaciones del mundo real y solucionar problemas comunes, por lo que puede adivinar cómo un reloj puede mejorar esta experiencia.

Resumen

En conclusión, el tubo láser de CO2 de 100W es una herramienta potente y versátil para aplicaciones de grabado y corte. Con su alta precisión, durabilidad y rentabilidad, ofrece un valor significativo tanto para uso profesional como para aficionados. Comprender las especificaciones, el proceso de instalación y los consejos de mantenimiento puede ayudarle a maximizar la eficacia y longevidad de su cortadora o grabadora láser.

Tanto si está buscando lanzar un pequeño negocio como mejorar sus proyectos creativos, invertir en un tubo láser de CO2 de 100W puede desbloquear nuevas posibilidades y elevar su trabajo al siguiente nivel. Siguiendo las directrices proporcionadas en esta completa guía, estará bien equipado para tomar una decisión informada y disfrutar de todo el potencial de su láser de CO2 de 100W.

Preguntas frecuentes

¿Cuál es la vida útil de un tubo láser de CO2 de 100 W?

Un tubo láser de CO2 de 100 W suele tener una vida útil de entre 10.000 y 12.000 horas si se utiliza en condiciones óptimas. Un mantenimiento adecuado puede ayudar a maximizar su longevidad.

¿Qué materiales se pueden grabar y cortar con un láser de CO2 de 100 W?

Un láser de CO2 de 100W puede grabar y cortar eficazmente materiales como madera, acrílico, vidrio y ciertos tipos de metal. Esta versatilidad lo convierte en una herramienta excelente para diversas aplicaciones.

¿Qué importancia tiene la fuente de alimentación de un tubo láser de CO2 de 100 W?

La fuente de alimentación es vital para un tubo láser de CO2 de 100 W, ya que influye directamente en el rendimiento y la vida útil del tubo. Garantizar una fuente de alimentación adecuada mejorará la eficiencia y la fiabilidad del funcionamiento.

¿Cuáles son los consejos de mantenimiento habituales para un tubo láser de CO2 de 100 W?

Para garantizar un rendimiento óptimo y la longevidad de su tubo láser de CO2 de 100 W, límpielo con regularidad, compruebe si presenta algún signo de daño y guárdelo correctamente. La aplicación de estas prácticas de mantenimiento ayudará a que su láser siga funcionando eficazmente.

¿Existen garantías para los tubos láser de CO2 de 100 W?

Sí, la mayoría de los tubos láser de CO2 de 100 W suelen incluir un periodo de garantía de 6 a 12 meses que cubre los defectos de fabricación, ofreciendo opciones de reparación o sustitución.