Verá que un tubo láser de CO2 de 100 vatios no siempre es mejor o peor que otras potencias. Tiene puntos fuertes especiales para determinados trabajos. La mejor elección depende de lo que necesite. Piense en el material, en su presupuesto y en cómo quiere utilizarlo. Compruebe el tabla siguiente para saber qué potencia se adapta a cada trabajo:

| Tipo de aplicación | Lo mejor para | Limitado Para |

|---|---|---|

| Madera | Madera contrachapada, MDF, balsa, madera dura (hasta 1/2") | ✖ Madera gruesa (más de 3/4") |

| Acrílico | ✔ Cortes lisos y limpios (hasta 1/2" de grosor) | ✖ Corte de metal desnudo |

| Cuero y tela | ✔ Grabado y corte de precisión | ✖ Piedra y vidrio (sobre todo grabado) |

| Metales | ✔ Grabado de aluminio anodizado y metales revestidos | ✖ Corte de metal desnudo |

Un tubo láser 100-wCO22 funciona bien con materiales de grosor medio. Puede grabar pequeños detalles. Puede soldar chapas finas en laboratorios de investigación. Puede elegir la potencia adecuada teniendo en cuenta estos sencillos puntos.

Principales conclusiones

- Un tubo láser de CO2 de 100 W puede realizar muchos trabajos. Sirve para cortar y grabar cosas como madera, acrílico y cuero. Piense en los materiales que más utiliza y en el tamaño de sus proyectos. Esto le ayudará a elegir el potencia correcta del tubo láser. Elegir la potencia adecuada da buenos resultados y ahorra dinero. Los tubos de mayor potencia, como los de 100 W, cortan más rápido los materiales gruesos. Pero necesitan más potencia y un sistema de refrigeración más potente. Los tubos de menor potencia son ideales para principiantes y proyectos pequeños y cuidadosos. Te ofrecen un mejor control y consumen menos energía. Elija siempre un tubo láser que se ajuste a sus necesidades. Así evitarás errores y obtendrás los mejores resultados.

100 W frente a otros tubos láser de CO2

Principales diferencias

Cuando se compara un 100 vatios CO22 tubo láser a otras potencias, se notan claras diferencias de rendimiento, coste y aplicación. La tabla siguiente muestra cómo destaca cada potencia en umbral de cocción y calidad de grabado:

| Vatios | Umbral de disparo | Calidad de grabado |

|---|---|---|

| 40W | 2% | Mayor detalle |

| 100W | 11% | Corte más grande, menos detalle |

Un tubo de 40 W le ofrece un grabado fino y un umbral de cocción bajo. Puede trabajar con materiales delicados y conseguir detalles nítidos. El tubo láser de 100 WCO22 necesita más potencia para empezar, pero admite materiales más gruesos y trabajos más rápidos. Se cambia algo de detalle de grabado por más fuerza de corte.

También hay que tener en cuenta el coste y el público objetivo. La tabla siguiente le ayudará a ver dónde encaja cada tubo:

| Potencia del láser | Gama de precios (USD) | Público destinatario |

|---|---|---|

| 60W | 2,000-3,500 | Aficionados |

| 100W | 3,500-6,000 | Pequeñas empresas |

| 130W | 5,000-8,000 | Mayor ROI |

Un tubo de 60 W cuesta menos y es adecuado para trabajos de hobby. El Tubo láser 100-wCO22 cuesta más, pero se obtiene mayor velocidad y cortes más gruesos. Si dirige una pequeña empresa, este tubo le ofrece un buen equilibrio entre precio y prestaciones.

Ventajas e inconvenientes

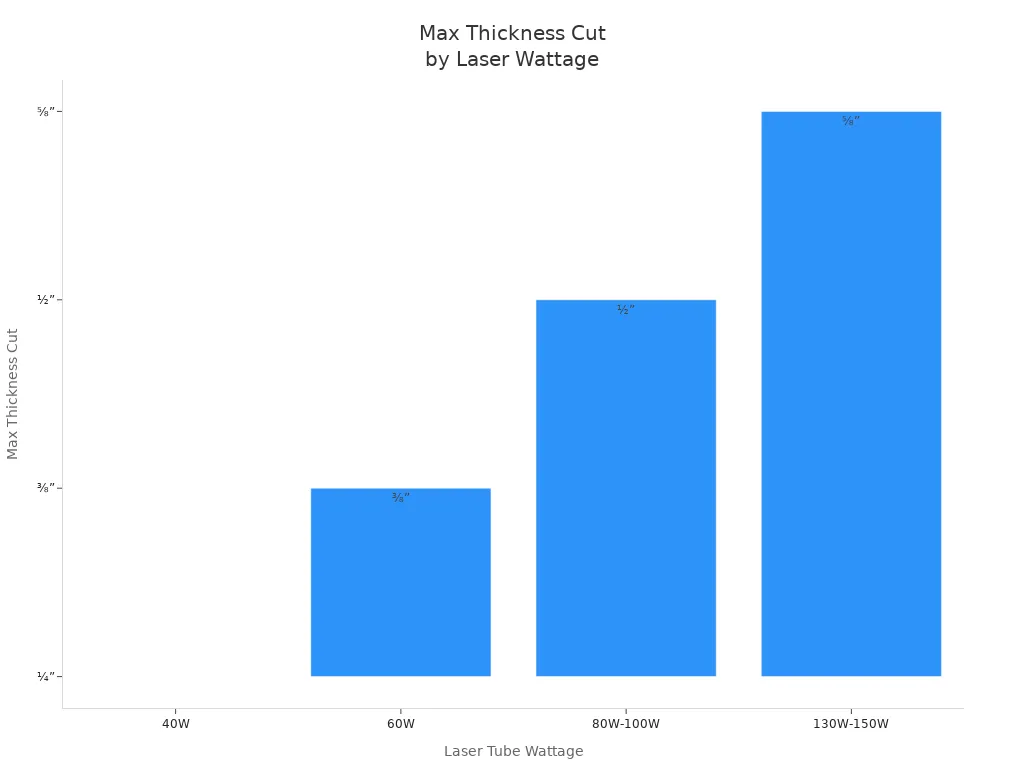

A la hora de elegir un tubo láser de CO2, debe tener en cuenta el grosor y la velocidad de corte. La siguiente tabla muestra lo que puede esperar:

| Vatios | Espesor máximo de corte | Velocidad |

|---|---|---|

| 40W | ¼" | Velocidad más baja |

| 60W | ⅜" | Velocidad más baja |

| 80W-100W | ½" | Baja a media adolescencia |

| 130W-150W | ⅝" | Velocidad máxima |

Si desea cortar materiales más gruesos o trabajar más rápido, los tubos de mayor potencia le ayudarán. El tubo láser de 100 wCO22 le permite cortar hasta ½ pulgada de grosor y mantiene una buena velocidad. Los tubos de menor potencia funcionan mejor para materiales finos y grabados detallados. Los tubos de mayor potencia cortan incluso materiales más gruesos, pero cuestan más y consumen más energía.

Consejo: Adapte siempre la potencia del láser al material principal y al tamaño del proyecto. Así ahorrará costes y obtendrá los mejores resultados.

Tubo láser de CO2 de 100W Pros

Versatilidad

Puede utilizar un Tubo láser de CO2 de 100 vatios para muchas tareas diferentes. Este tubo funciona con una amplia gama de materiales. Consigue grabados precisos en acrílico, madera y cuero. Puede crear letreros, artículos decorativos y regalos personalizados. El tubo trabaja con cartón, cerámica, vidrio, papel, piedra y madera. Consigue diseños de alto contraste y texturas en madera. Puede grabar patrones intrincados y cortar materiales gruesos. El tubo corta acrílico de hasta 20 mm y madera contrachapada de hasta 10 mm en una sola pasada. Esta versatilidad le ayuda a satisfacer muchas necesidades de producción.

- Graba diseños detallados en acrílico y madera

- Adecuado para señalización, regalos y decoración

- Trabaja con cartón, cerámica, vidrio, cuero, papel, piedra y madera

- Corta acrílico de hasta 20 mm y contrachapado de hasta 10 mm en una sola pasada

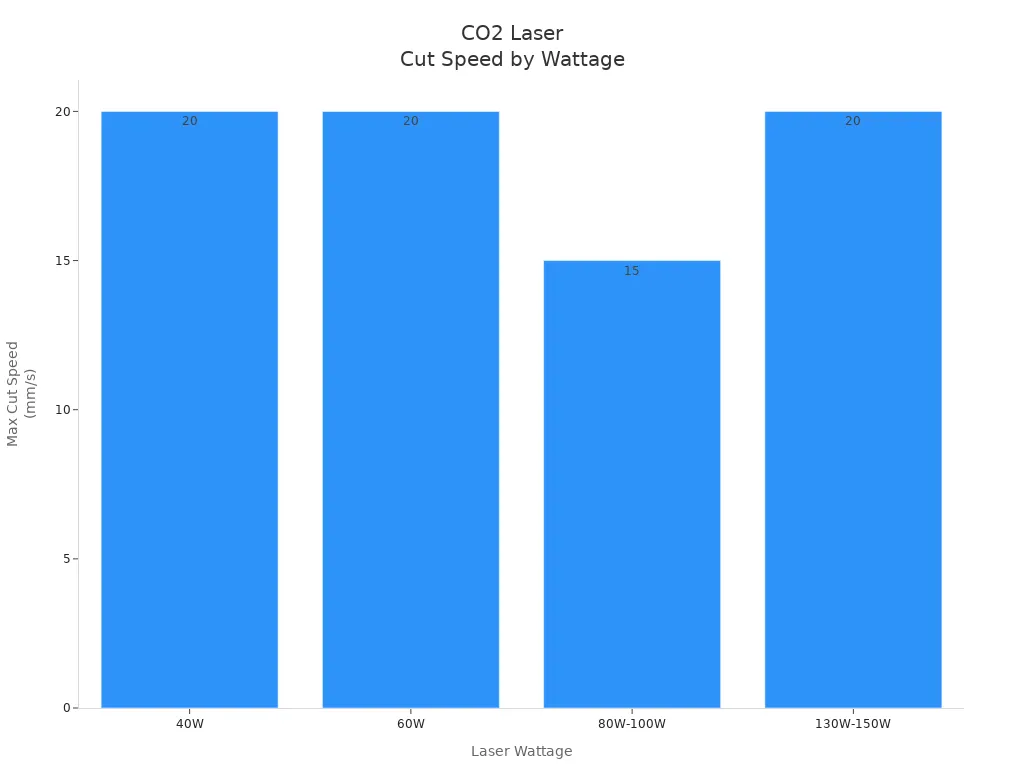

Potencia de corte

Usted obtiene alto rendimiento de corte con un tubo láser de CO2 de 100 W. El tubo corta materiales más gruesos que los tubos de menor potencia. Verá una mayor velocidad y mejor calidad al trabajar con madera, acrílico y cuero. El tubo puede cortar hasta ½ pulgada de grosor con facilidad. Puede terminar los trabajos rápidamente y mantener la producción en movimiento. En la tabla siguiente se muestra la comparación entre el tubo de 100 vatios y otras potencias para el corte y la velocidad.

| Vatios | Espesor máximo | Ajuste de potencia (%) | Velocidad de corte (mm/s) |

|---|---|---|---|

| 40W | ¼" | 60-90% | 5-20 |

| 60W | ⅜" | 60-90% | 5-20 |

| 80W-100W | ½" | 60-90% | 10-15 |

| 130W-150W | ⅝" | 60-90% | 15-20 |

Observará que el tubo láser de CO2 de 100 W ofrece un equilibrio entre potencia de corte y velocidad. Obtendrá un rendimiento fiable para la mayoría de los materiales. Puede conseguir un buen rendimiento de grabado y calidad de corte sin el elevado coste de los tubos industriales.

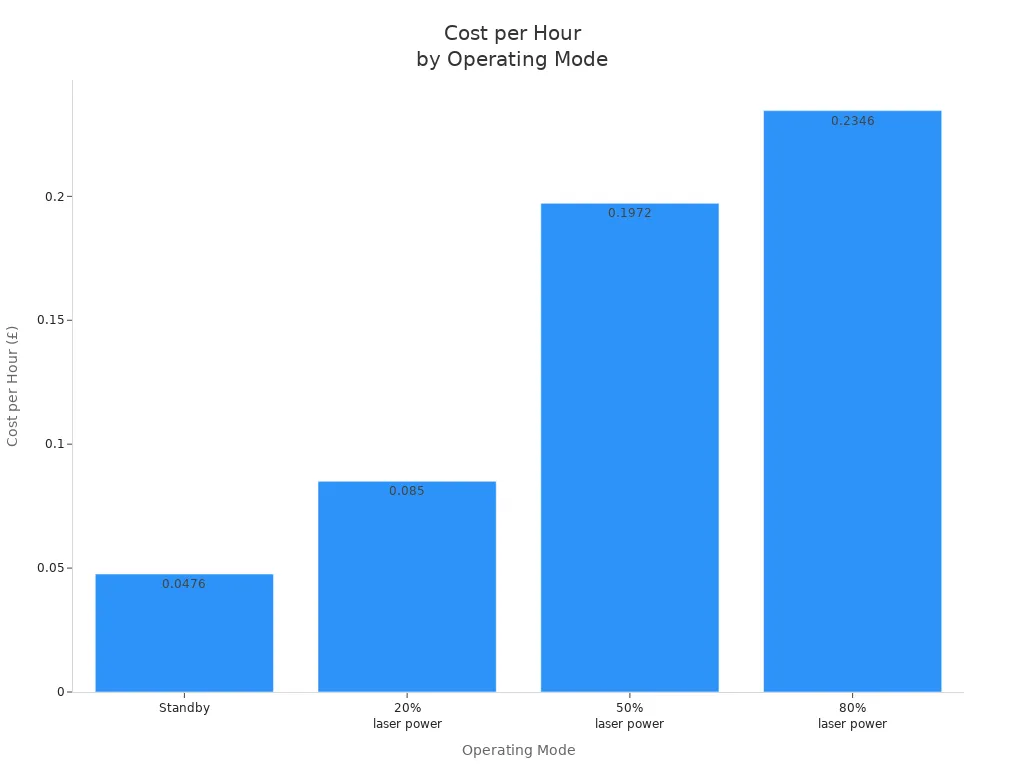

Eficiencia de costes

Ahorrará dinero con un tubo láser de CO2 de 100 W. El tubo consume menos energía que los modelos de mayor potencia. Pagará menos por el funcionamiento y el mantenimiento. El tubo dura más que muchos otros tubos de vidrio. Obtendrá más horas de uso antes de sustituirlo. La siguiente tabla muestra el coste por hora a diferentes niveles de potencia.

| Modo de funcionamiento | Potencia utilizada (W) | Coste/hora |

|---|---|---|

| En espera | 140 | £0.0476 |

| Ajuste de la potencia del láser 20% | 250 | £0.0850 |

| Ajuste de potencia del láser 50% | 580 | £0.1972 |

| Ajuste de la potencia del láser 80% | 690 | £0.2346 |

Usted gasta menos en energía y obtiene más tiempo de producción. El tubo láser de CO2 de 100 W es más asequible que un láser RF de CO2. Obtendrá una vida útil más larga que la mayoría de los modelos de tubos láser de vidrio de CO2. Puede dirigir su negocio con costes más bajos y un rendimiento constante.

Consejo: Elija un tubo láser de co2 de 100w si desea un equilibrio entre potencia, velocidad y coste para sus necesidades de producción.

Tubo láser CO2 100W Contras

Necesidades de energía

Debe tener en cuenta mayores requisitos de potencia de un tubo láser de CO2 de 100 W. Este tubo consume más electricidad que los modelos de menor potencia. Debe utilizar una fuente de alimentación más potente y un sistema de refrigeración más eficaz. El tubo genera más calor, por lo que debes mantenerlo frío para evitar daños.

- Los tubos láser de CO2 de diferentes potencias tienen necesidades de potencia únicas en función de los materiales que procesen.

- Los tubos de mayor potencia, como los de 100 W, funcionan mejor para cortar materiales más gruesos.

- Los tubos de menor potencia se adaptan a las tareas de grabado y consumen menos energía.

- Los sistemas de refrigeración para tubos de 100 W deben soportar más calor que los de tubos más pequeños.

En El umbral mínimo de encendido de una válvula de 100 W suele estar en torno a 12%.. Los tubos de menor potencia pueden empezar en 8%. Es posible que el tubo de 100W necesite más potencia para empezar a emitir láser, lo que puede ser demasiado para trabajos de grabado delicados. Los usuarios a menudo informan de que el funcionamiento a 12% garantiza un rendimiento fiable, pero esto puede limitar su capacidad para trabajar con materiales finos o sensibles.

Nota: Si tiene previsto grabar detalles finos o trabajar con materiales finos, un tubo de menor potencia puede ofrecerle un mejor control y un menor consumo de energía.

Talla

Debe comprobar el tamaño físico de un tubo láser de CO2 de 100 W antes de la instalación. Este tubo es más largo y ancho que los modelos más pequeños. La dirección la longitud estándar es de unos 1480 mm y el diámetro de 80 mm.

| Longitud | Diámetro |

|---|---|

| 1480 mm | 80 mm |

El mayor tamaño significa que se necesita un bastidor de máquina más grande. En algunas máquinas láser no cabe un tubo de 100 W. Es posible que tenga que mejorar su espacio de trabajo o elegir un modelo compatible. El tamaño del tubo también dificulta su traslado o sustitución. Si dispone de un espacio limitado, debe medir cuidadosamente antes de comprar.

No para metal

No se puede utilizar un tubo láser de CO2 de 100 W para cortar o grabar la mayoría de los metales. Este tubo funciona mejor con materiales no metálicos como madera, acrílico y cuero. Puede marcar o grabar metales revestidos o anodizados, pero no obtendrá cortes profundos ni grabados resistentes.

- Un láser de CO2 de 100 W puede marcar o grabar algunos metalespero no puede cortarlos.

- Para cortar metales, debe utilizar un grabador láser de fibra. Los láseres de fibra procesan los metales mucho mejor que los láseres de CO2.

- El tubo de 100 W está diseñado para el grabado y el corte ligero en materiales finos no metálicos.

Si necesita procesar metal, debe buscar una tecnología diferente. El tubo láser de CO2 de 100 W le ofrece grandes resultados en materiales no metálicos, pero no puede realizar trabajos de corte de metal.

Consejo: Adapte siempre su tubo láser a su material principal. Si trabaja con metal, elija un láser de fibra. Si se centra en materiales no metálicos, un tubo de CO2 de 100 W es una buena elección.

Tubos láser de CO2 de bajo vataje

Beneficios

Los tubos láser de CO2 de menor potencia son buenos por muchas razones. Estos tubos cuestan menos que modelos más fuertes. Son una elección inteligente para principiantes o usuarios aficionados. Se paga menos por la electricidad porque se utiliza menos energía. El mantenimiento es sencillo y las piezas son fáciles de cambiar. No necesita un gran sistema de refrigeración, por lo que ahorra espacio y dinero.

Estos tubos son ideales para proyectos delicados. Puede grabar detalles finos en objetos delgados como papel, tela y cuero. Le ofrecen un buen control, para que no queme ni deforme las superficies blandas. Puede configurar su máquina rápidamente y mantener su área ordenada.

Consejo: Si quieres empezar poco a poco o hacer manualidades, un tubo de menor potencia te ayuda ahorrar dinero y energía.

Inconvenientes

Los tubos láser de CO2 de menor potencia tienen algunas limitaciones. Estos tubos no pueden cortar materiales gruesos. Puede tener problemas con trabajos que necesiten más potencia. El corte es más lento, por lo que cada trabajo lleva más tiempo. No puede cortar materiales duros como madera dura gruesa o acrílico de más de ¼ de pulgada.

La siguiente tabla muestra la comparación entre los tubos de menor potencia y los tubos de mayor potencia. Modelos de 100 W y superiores:

| Gama de vatios | Profundidad de corte | Velocidad | Gama de materiales |

|---|---|---|---|

| Menor potencia | Limitado a materiales más finos | Más lento | Adecuado para trabajos delicados |

| 100 W y superior | Capaz de cortar materiales más gruesos | Más rápido | Puede manipular materiales más densos como los metales |

Es posible que no pueda utilizar muchos tipos de materiales. Los tubos de menor potencia son mejores para grabados ligeros y trabajos pequeños. Si necesitas cortar madera gruesa o hacer pedidos grandes, debes elegir un tubo de mayor potencia.

Nota: Elija siempre el tubo láser para sus trabajos principales. Los tubos de menor potencia son buenos para manualidades y muestras, pero no para cortes pesados.

Tubos láser de CO2 de mayor potencia

Ventajas

Los tubos láser de CO2 de mayor potencia son muy resistentes. Cortan materiales gruesos rápida y fácilmente. Puede utilizarlos en madera dura, acrílico y plásticos resistentes. Mucha gente elige estos tubos para grandes trabajos en fábricas. Estos tubos funcionan bien para grandes proyectos y materiales duros. Consigues un corte más rápido, por lo que acabas antes los trabajos.

- Cortar hasta ⅝ pulgada de grosor en un solo intento.

- Finalice grandes pedidos de forma rápida y sencilla.

- Bueno para trabajos duros en fábricas y rotulación.

Con tubos de mayor potenciasu negocio puede crecer. Puede hacer trabajos más grandes y ofrecer más ayuda a los clientes. Dedica menos tiempo a cada proyecto y consigue más. Pero estos tubos cuestan mucho al principio. También hay que pagar más por la electricidad y la refrigeración.

Consejo: Elige un tubo de mayor potencia si quieres hacer crecer tu negocio o cortar material grueso.

Desventajas

Los tubos láser de CO2 de mayor potencia plantean algunos problemas. Necesitan más cuidado y limpieza. Hay que revisarlos a menudo para que sigan funcionando. Estos tubos son más complicados, por lo que se invierte más tiempo y dinero en repararlos. No duran tanto como los tubos de potencia media.

La siguiente tabla muestra cómo el mantenimiento modifica su trabajo y sus costes:

| Aspecto del mantenimiento | Impacto en la productividad | Impacto en el coste |

|---|---|---|

| Mantenimiento periódico | Reduce el tiempo de inactividad | Reducción de costes |

| Mantenimiento excesivo | Aumenta el tiempo de inactividad | Aumento de los costes |

| Complejidad del láser de CO2 | Requiere más mantenimiento | Mayores costes |

Si no limpias y revisas el tubo, puede estropearse más. Esto significa que dejará de funcionar y gastará más dinero. También tienes que comprar tubos nuevos más a menudo, lo que supone un coste adicional.

Nota: Prevea más limpieza y ahorre dinero para tubos nuevos si elige un tubo de alto vataje. Esto te ayudará a evitar problemas y a mantener tu trabajo en marcha.

El mejor tubo láser de CO2 para sus necesidades

Uso aficionado

Si te gusta hacer manualidades, prueba con un tubo de menor potencia. La mayoría de los usuarios aficionados eligen Tubos de 40 ó 60 W. Estos tubos son buenos para proyectos pequeños y cosas finas. Puede grabar madera, acrílico, cuero y papel con gran detalle. Estas máquinas no necesitan mucho espacio. El precio es bajo, por lo que ahorrará dinero.

- 40W: Buena para grabar y cortar cosas finas como papel o tela.

- 60W: Funciona con materiales de grosor medio, como madera contrachapada o metales revestidos.

- 80W-100W: Ayuda con proyectos de hobby más grandes o materiales más gruesos.

Consejo: Empieza con un tubo de 40W o 60W para facilitar la instalación y el cuidado. Aumenta la potencia si tus proyectos son más grandes o difíciles.

Pequeña empresa

Si tiene una pequeña empresa, necesita más potencia y velocidad. Un tubo láser de CO2 de 60W a 100W trabaja más rápido y corta material más grueso. Puede cortar madera de hasta 10 mm y acrílico de hasta 12 mm. Estos tubos duran más y le ayudan a terminar los trabajos más rápido.

He aquí una guía rápida:

| Potencia | Vida útil | Mejores casos de uso |

|---|---|---|

| 40W | 1500-3000 horas | Grabado/corte de materiales finos (≤3mm) |

| 60W | 2500-4000 horas | Materiales de grosor medio (≤6mm) |

| 80W-100W | 3000-8000 horas | Corte resistente (≤12mm), producción más rápida. |

Piensa en tu presupuesto, el espacio y los materiales que utilizas. Un tubo de 100 W cuesta más, pero ayuda con pedidos más grandes y materiales más gruesos. Si quieres que tu negocio crezca, elige un tubo que se adapte a tus necesidades.

Nota: Elija un tubo con potencia suficiente para sus trabajos principales. Esto mantiene tu trabajo en movimiento y evita retrasos.

Industrial

Si trabaja en una fábrica, necesita una gran potencia para trabajos grandes. Elija un tubo láser de CO2 de 100W o más. Estos tubos cortan rápidamente materiales gruesos y metales finos. Puede terminar grandes pedidos y cumplir plazos ajustados.

- Los tubos de mayor potencia (100W+) son los mejores para trabajos duros y material grueso.

- Puedes utilizar ajustes más bajos para que el tubo dure más y ahorrar energía.

- Las máquinas de las fábricas necesitan más espacio y mejores sistemas de refrigeración.

| Gama de vatios | Adecuado para | Tipo de usuario |

|---|---|---|

| 30-60W | Materiales finos, grabado | Artesanía a pequeña escala |

| 60-100W | Materiales más gruesos, producción más rápida | Ampliación de empresas |

| 100W+ | Materiales gruesos o metales finos, grandes volúmenes | Aplicaciones industriales |

Consejo: Adapte la potencia de su tubo láser a sus objetivos de trabajo y materiales principales. Esto le ayudará a obtener buenos resultados y a controlar sus costes.

Existen grandes diferencias entre Tubos láser de CO2 de 100 W y otras potencias. La tabla siguiente muestra lo que es importante:

| Aspecto | Tubo láser de CO2 de 100 W | Otras potencias |

|---|---|---|

| Necesidades de energía | Necesita más potencia para el material grueso | Necesita menos potencia para cosas finas |

| Refrigeración | Necesita una fuerte refrigeración | Necesita menos refrigeración |

| Utilización | Bueno para mucho uso | Bueno para aficiones o trabajos ligeros |

Elija su tubo láser en función de sus proyectos principales. Piense en estas cosas antes de comprar:

- Comprueba si tus materiales necesitan mucha potencia o refrigeración.

- Asegúrese de que el tubo encaja en su máquina.

- Fíjate en la potencia nominal, no sólo en la potencia más alta.

- Decide si quieres detalles finos o cortar cosas gruesas.

Consejo: Elija la potencia que se ajuste a sus necesidades, no sólo el número más alto. Así evitarás errores y obtendrás los mejores resultados.

PREGUNTAS FRECUENTES

¿Qué materiales se pueden cortar con un tubo láser de CO2 de 100 W?

Puede cortar madera, acrílico, cuero, cartón y algunos plásticos. Puede grabar metales revestidos, vidrio y cerámica. No puede cortar metales desnudos.

Consejo: Compruebe siempre la seguridad y compatibilidad del material antes de iniciar su proyecto.

¿Cuánto dura un tubo láser de CO2 de 100 W?

La mayoría de los tubos láser de CO2 de 100 W duran entre 3.000 y 8.000 horas. Puede prolongar su vida útil con una refrigeración adecuada y una limpieza periódica.

| Tipo de tubo | Vida media |

|---|---|

| Vidrio | 3.000-8.000 horas |

| RF | Más de 10.000 horas |

¿Necesita refrigeración especial para un tubo láser de CO2 de 100 W?

Necesitas un enfriador de agua o un sistema de refrigeración avanzado para un tubo de 100W. La refrigeración por aire no funciona para este nivel de potencia.

- Refrigerador de agua recomendado

- Revisiones periódicas del líquido refrigerante

- Evitar el sobrecalentamiento

¿Puede actualizar su máquina para utilizar un tubo láser de CO2 de 100 W?

Puede actualizarla si el bastidor de su máquina se ajusta al tubo y su fuente de alimentación admite una potencia superior. Es posible que tengas que ajustar los sistemas de refrigeración y seguridad.

Nota: Compruebe siempre las especificaciones de su máquina antes de actualizarla.