Ready to get your laser back in top shape? CO2 laser tube troubleshooting helps you spot issues fast and fix them before they slow you down. Quick solutions keep your Feiju Laser machine running without long delays. You do not need to be an expert to use these tricks. Anyone can follow these tips and see real results.

Keep your laser working smoothly—save time, reduce stress, and cut better every day!

Principales conclusiones

- Checking for problems often helps you find issues early. This stops small issues from getting worse. You save time and money when you fix things early.

- Keep your CO2 laser tube clean and working well. Clean the mirrors and lenses often. This helps your machine cut better.

- Look at your power settings and cooling system a lot. Good settings and cooling stop the machine from getting too hot. This also keeps the power strong.

- Make sure your laser beam is lined up right. This helps you make accurate cuts. If the beam is not lined up, cuts can be uneven. You may get bad results.

- If you see flickering or weak light, check your power supply. Also, look at the tube to see if it is okay. Finding problems early can save you from expensive fixes.

Why Troubleshooting Matters

Machine Performance

You want your laser to cut well and fast each time. Troubleshooting helps you find problems before they get worse. If you check your Feiju Laser machine often, it works better. Small problems can become big ones if you ignore them. This can slow down your cutting and make it less accurate.

Here’s a quick look at how troubleshooting affects your results:

| Troubleshooting Aspect | Impact on Speed and Accuracy |

|---|---|

| Adjusting speed and power | Changing these can help your cuts look better. Lower speed or more power can make cuts smoother. |

| Optical component alignment | Lining up the parts right helps the beam focus. This makes your cuts more exact. |

| Fume extraction | Good fume extraction keeps smoke away. This gives you a clear path and steady results. |

Even small changes can help a lot. Checking your machine often stops surprises. If you know your laser’s details and keep the parts lined up, you get better cuts. Many CO2 laser repairs start with these easy checks.

Maintenance Benefits

Troubleshooting is not just for fixing broken things. It helps your machine stay healthy so you can work without worry. Doing regular checks helps you avoid losing time and money. Shops that check their machines often do not fall behind and use their tools well.

Tip: Checking your machine often can find problems early. This saves you time and money.

Here are some ways troubleshooting helps you:

- Checking often finds problems before they stop your work.

- Keeping up with care helps your machine cut well every time.

- Good care can help your machine last longer.

- Stopping big problems saves you money on repairs.

You can make your CO2 laser tube last longer by doing a few easy things:

- Keep the cooling system clean and working well.

- Clean the mirrors and lenses to stop them from getting too hot or worn out.

- Use the right power settings and do not overuse the tube.

If you do these things, you will not need as many CO2 laser repairs. You will spend more time making things and less time fixing. That is why troubleshooting is important for every Feiju Laser owner.

CO2 Laser Tube Troubleshooting

When your Feiju Laser machine acts up, you want answers fast. This section gives you the best CO2 laser tube troubleshooting tricks for the most common problems. You will learn how to spot issues, what causes them, and how to fix them step by step. Let’s dive in!

Power Loss

Power loss can slow down your work or even stop your laser from cutting. You might notice your machine struggles with thick materials or leaves uneven cutting depth. Here’s how you can tackle this:

- Check for visible damage on the laser tube and power supply. Look for cracks, burn marks, or melted wires.

- Clean all optical components. Dust or residue on mirrors and lenses can block the beam and cause power drops.

- Verify your power settings. Make sure you set them correctly for your material and job.

- Inspect for electrical issues. Burned or loose wires can cause sudden power loss or make the laser not fire at all.

| Cause of Power Loss | Descripción |

|---|---|

| Declared Lifetime | Power drops often happen after 50-70% of the tube’s declared lifetime. |

| High Operating Temperature | If the tube runs above 30ºC, it wears out much faster. At 40ºC, it can fail quickly. |

| Prolonged Maximum Power Use | Running at max power for too long shortens the tube’s life. Use a higher wattage tube if needed. |

| Optimal Temperature Range | Keep the tube between 10-25ºC for best results. Higher temps mean less power and more wear. |

Tip: If you see a sudden drop in cutting power or uneven cutting depth, check your tube’s age and temperature first. Sometimes, a laser tube replacement is the only fix.

Unstable Output

Does your laser cut fine one minute and weak the next? Unstable output can ruin your projects and cause frequent laser tube failures. This usually points to problems with the power supply, dirty optics, or overheating.

- Make sure your power supply delivers steady voltage.

- Clean all mirrors and lenses.

- Check for loose wires or connectors.

- Watch for signs of overheating, like a hot tube or warm water lines.

If you keep seeing uneven cutting depth, unstable output might be the cause. Regular CO2 laser tube troubleshooting helps you catch these issues early.

Cooling Issues

A hot laser tube spells trouble. Overheating leads to power loss, shortens tube life, and can even cause cracks. Here’s how you can keep things cool:

- Control the working current. Never push the tube past its rated current.

- Take breaks during long jobs. Give your machine time to cool down.

- Inspect your cooling system often. Look for leaks, blockages, or dirty water.

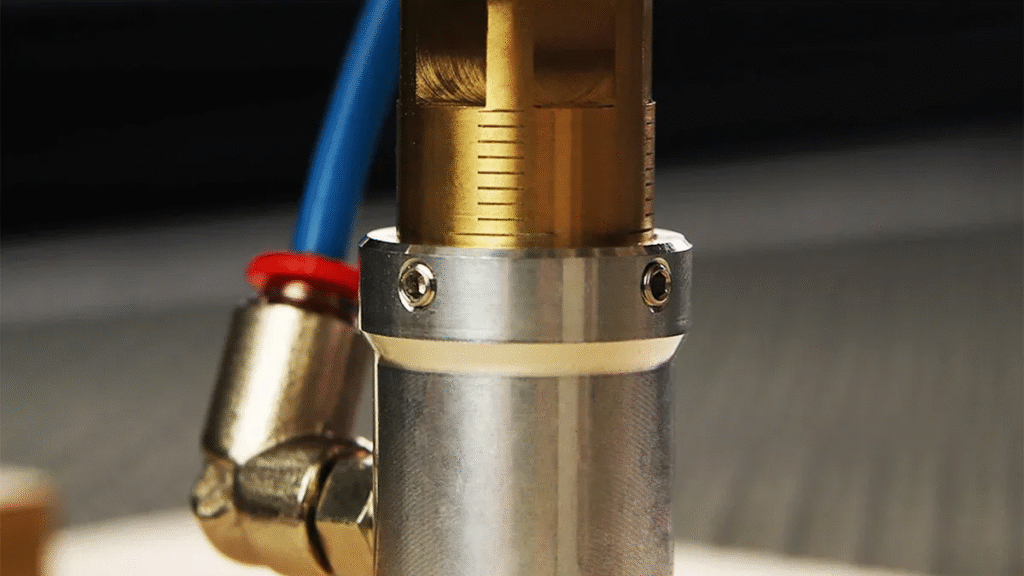

- Use a dedicated CO2 laser chiller for precise temperature control.

- Change the cooling water every 3–6 months and clean the water lines.

- Place your machine in a cool, well-ventilated area.

Note: If your tube keeps overheating, you may need a laser tube replacement sooner than expected.

Arcing or Sparking

Arcing or sparking is scary and dangerous. It can damage your tube and even start a fire. Here’s what to look for:

- Bad connections at the tube ends. Redo and insulate them if needed.

- Dirty or conductive cooling water. Always use clean, distilled water.

- Tube problems like micro-cracks or worn electrodes.

- External shorting or eroded electrode coatings.

| Safety Precaution | Descripción |

|---|---|

| Maintain a stable power supply | Use a regulated supply to avoid power spikes. |

| Activate cooling water first | Always turn on the cooling before the laser. |

| Stable surface placement | Keep your machine on a flat, stable surface. |

| Use minimal laser current | Don’t overwork the tube. |

| Clean circulating water | Use deionized or distilled water. |

| Regular lens cleaning | Clean lenses to prevent dust and burning. |

Always turn off your machine and unplug it before checking for sparks or arcing. If you see sparks, stop using the machine and call Feiju Laser support.

Beam Misalignment

Beam misalignment causes uneven cutting depth, rough edges, and poor engraving. You might notice your cuts look wider or less sharp than usual. Here’s a simple way to check alignment:

- Place masking tape over the hole in front of mirror 3.

- Move the laser head to the top right corner and fire a quick test shot.

- Repeat this in the front left and back left corners.

- Compare the dots. If they don’t line up, your beam is misaligned.

- Adjust the mirrors or the tube until all dots match.

- Align mirrors so the beam hits each one dead center.

- Make sure the tube points straight into the first mirror.

- Keep the beam vertical for straight, clean cuts.

Proper alignment means your Feiju Laser machine will cut with precision every time.

Tube Leaks or Cracks

Leaks or cracks in your tube are serious. They can cause arcing, weak brightness, or even total failure. Watch for these signs:

- You hear electrical noise or see sparks.

- The tube glows white instead of pink, or the brightness is very weak.

- Your machine struggles to cut acrylic at full power and low speed.

- The power meter shows less than half the rated power.

If you spot a leak or crack, you have two main options:

| Repair Option | Descripción |

|---|---|

| Professional Services | Experts can refill, refurbish, or repair your tube. They may replace mirrors or re-gas the tube. |

| DIY Methods | For small cracks, use two-component epoxy. Pressure test the tube after repair to check for leaks. |

- For broken water nipples or big cracks, consider professional re-gas services.

- Always pressure test after any repair.

If you keep having leaks, it may be time for a laser tube replacement.

Flickering or Weak Brightness

A flickering or dim laser beam means trouble. You might see the laser fade in and out or never reach full brightness. Common causes include:

- Power supply issues.

- Tube wear, cracks, or discoloration.

- Poor cooling or dirty water.

- Lack of regular maintenance.

Keep your power supply in good shape and check for signs of wear. If the tube looks old or discolored, a laser tube replacement may be needed. Regular CO2 laser tube troubleshooting can help you catch these problems before they get worse.

Loose Connections

Loose connections can make your laser act up. You might see power drops, uneven cutting depth, or even the laser not firing at all. Make sure all wires to the power supply and controller are tight and secure.

Loose or faulty wiring stops your tube from getting enough power. This leads to poor performance and frequent laser tube failures. Always check connections during your regular CO2 laser tube troubleshooting routine.

If you keep having trouble after checking everything else, a sustitución del tubo láser might be the best fix.

You now have a full set of CO2 laser tube troubleshooting tricks. Use these steps to keep your Feiju Laser machine running strong and avoid downtime. Regular checks and quick fixes mean more time creating and less time repairing!

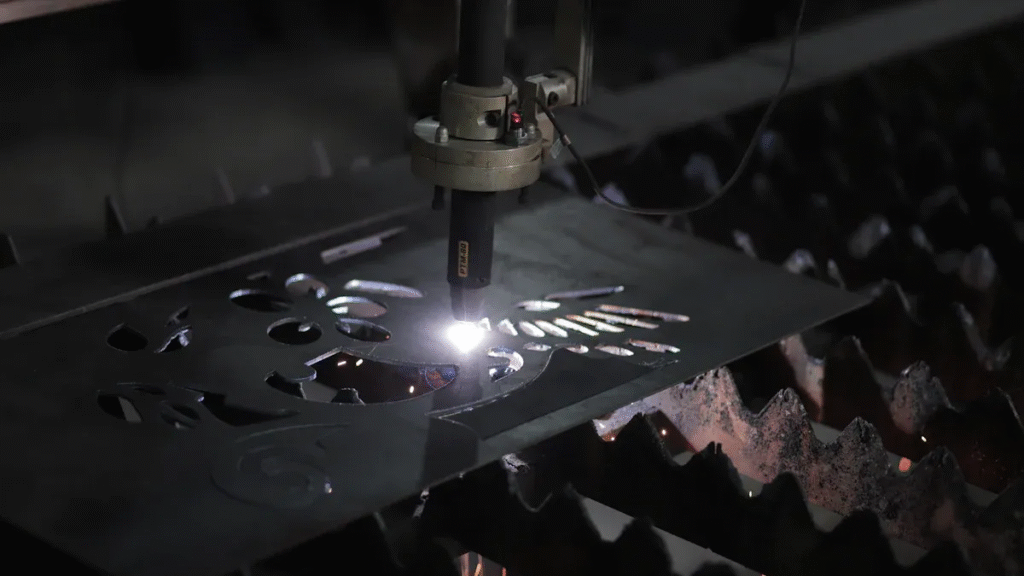

Common CO2 Laser Cutting Problems

When you use your Feiju Laser machine, you might run into some common CO2 laser cutting problems. These issues can mess with your cut quality and slow down your projects. Let’s look at the top problems and how you can fix them fast.

Misalignment

Misalignment is one of the most common CO2 laser cutting problems. You might notice your cuts look crooked or the laser doesn’t hit the same spot each time. This can lead to poor cuts and wasted material. Here’s what you can do:

- Check and adjust the belt tension. Loose belts can cause the laser head to move unevenly.

- Inspect the Y-axis shaft. Make sure all bolts are tight and there’s no extra movement.

- Align the laser beam. Use a beam visualization tool to check if the beam hits the same spot across the work area.

- If you spot misalignment, follow the standard beam alignment steps in your Feiju Laser guide.

Tip: Regular alignment checks keep your cut quality sharp and your machine running smoothly.

Focus Issues

Focus issues are another common CO2 laser cutting problem. If your laser isn’t focused right, you’ll see fuzzy lines, or the laser won’t cut through the material. Here’s a quick way to check and fix it:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inaccurate Focus Point | Wrong focal length or misaligned lens | Place a piece of cardboard at an angle. Engrave a straight line. Find the thinnest part of the line. Measure the distance from this point to the laser head. Adjust the focal length as needed. |

You can also use a focal ruler for more accuracy. Keeping your focus lens clean and set at the right height will help you avoid common CO22 laser cutting problems like burn marks or incomplete cuts.

Cutting Inconsistencies

Cutting inconsistencies show up as jagged edges, uneven depth, or even missing sections. These common CO2 laser cutting problems can happen for many reasons:

- Uneven bed or warped material

- Mirror misalignment

- Loose belts or guide rails

Here’s a quick table to help you spot and fix these issues:

| Problem | Causes | Solutions |

|---|---|---|

| Incomplete or Poor Cuts | Weak power, dirty lens, wrong speed | Measure output, clean lens, adjust speed |

| Jagged or Wavy Cuts | Loose belts, mechanical backlash | Adjust belts, replace worn parts |

| Uneven Cutting Depth | Uneven bed, mirror misalignment | Level bed, align mirrors |

If you keep your machine clean and check for loose parts, you can avoid the most common CO2 laser cutting problems. Feiju Laser’s troubleshooting guides give you step-by-step help for each issue.

Remember: Regular checks and quick fixes keep your cut quality high and your projects on track. If you ever get stuck, Feiju Laser support is ready to help.

You keep your Feiju Laser machine running strong when you check it often. Regular troubleshooting helps you spot small problems before they turn big. Clean the mirrors and lenses, remove dust, and keep your cooling system in top shape. These simple steps help your laser tube last longer and cut better. If you ever feel stuck, reach out to Feiju Laser for expert help. Your machine will thank you!

PREGUNTAS FRECUENTES

How often should I check my CO2 laser tube?

You should check your laser tube every week. Look for dust, leaks, or loose wires. Regular checks help you catch problems early and keep your Feiju Laser machine running strong.

What signs show my laser tube needs replacing?

Watch for weak power, flickering light, or strange noises. If your machine struggles to cut or engrave, your tube may need replacing. You can also check for cracks or leaks.

Can I fix a cracked laser tube myself?

Small cracks can sometimes be fixed with epoxy. Always test for leaks after. For big cracks or leaks, call Feiju Laser support. Safety comes first!

Why does my laser lose power during long jobs?

Your tube may overheat, or your cooling system may not work well. Take breaks, check the water, and keep your machine cool. This helps your laser keep its power.