Sie brauchen eine CO2-Laserquelle, die konstant klare Ergebnisse liefert. Präzision hilft Ihnen, perfekte Schnitte und Markierungen zu erzielen, selbst bei harten Formen. Zuverlässigkeit bedeutet, dass Sie sich darauf verlassen können, dass der Laser jeden Tag ohne Unterbrechung zuverlässig arbeitet. Dank seiner Vielseitigkeit können Sie ihn für viele Materialien und Aufgaben einsetzen. Wenn Sie sich für einen Laser entscheiden, denken Sie daran, was Ihre Arbeit erfordert und was Ihre Branche verlangt.

Wichtigste Erkenntnisse

- Wählen Sie eine CO2-Laserquelle, die Ihnen sehr deutliche Schnitte und Markierungen. So bleiben Ihre Entwürfe korrekt und sehen gut aus.

- Finden Sie Lasersysteme, die lange Zeit gut funktionieren. Eine gute Garantie und Unterstützung helfen Ihnen, Zeit und Geld für Reparaturen zu sparen.

- Wählen Sie eine CO2-Laserquelle, die mit vielen Materialien arbeiten kann. So können Sie verschiedene Projekte durchführen, ohne weitere Geräte kaufen zu müssen.

- Denken Sie an die Stromwahlen vor dem Kauf. Vergewissern Sie sich, dass die Leistung der Dicke Ihrer Materialien entspricht, um die besten Ergebnisse zu erzielen.

- Legen Sie bei Ihrer CO2-Laserquelle großen Wert auf Sicherheitsmerkmale. Vergewissern Sie sich, dass sie den Sicherheitsvorschriften entspricht, damit Ihr Arbeitsplatz und Ihre Mitarbeiter sicher sind.

CO2-Laserquelle Übersicht

Präzision

Sie möchten, dass Ihre CO2-Laserquelle jedes Mal scharfe und klare Ergebnisse liefert. Präzision ist sehr wichtig für kleine Designs oder wenn Sie exakte Schnitte benötigen. Die besten Marken sind dafür bekannt, dass ihre Lasersysteme sehr genau sind. In der folgenden Tabelle finden Sie einige Top-Marken, die für ihre hohe Präzision bekannt sind:

| Marke | Beschreibung |

|---|---|

| TRUMPF | Ein führendes Unternehmen in der Lasertechnologie, das eine Vielzahl von CO2-Lasersystemen anbietet und nach ISO 9001 zertifiziert ist. |

| Viavi Lösungen | Stellt kommerzielle und OEM-Lasermarkierungssysteme her, die für ihre Qualität in der Verteidigung und Industrie bekannt sind. |

| Warren-Knight | Bietet seit 1908 hochwertige Präzisionslaserinstrumente für die Industrie an und setzt dabei auf Innovation. |

| Westbrook Engineering | Bietet innovative Lösungen für die Herstellung von Maschinen, einschließlich Lasern. |

| Newport Corporation | Anbieter von fortschrittlichen Laserlösungen für industrielle und wissenschaftliche Märkte. |

| Novanta | Entwickelt Präzisionsbewegungsprodukte und Lasersysteme für verschiedene Branchen. |

Mit diesen Marken erhalten Sie saubere Schnitte und klare Markierungen. Wenn Sie sich für eine CO2-Laserquelle entscheiden, achten Sie auf eine gute Kontrolle und gleichbleibende Genauigkeit. Dies hilft Ihren Produkten, die strengen Qualitätsanforderungen zu erfüllen.

Verlässlichkeit

Sie brauchen eine CO2-Laserquelle, die jeden Tag gut funktioniert. Zuverlässigkeit bedeutet, dass Ihr Gerät weniger ausfällt und weniger Reparaturen benötigt. Die meisten CO2-Laserröhren halten zwischen 2.000 und 10.000 Stunden.. Einige, wie die KT-Laserquellen von Kern, arbeiten mindestens 10.000 Stunden lang. Einige halten sogar bis zu 20.000 oder 30.000 Stunden. Dank dieser langen Lebensdauer können Sie Ihre Arbeit ohne viele Unterbrechungen fortsetzen.

Support und Garantie sind ebenfalls wichtig für die Zuverlässigkeit. Die besten Marken bieten starke Garantien und hilfreiche Unterstützung. Hier ist eine kurze Liste dessen, was Sie bekommen können:

- Epilog Laser: 2 Jahre Garantie, Support in den USA, Mo-Fr, 6-17 Uhr MST.

- Trotec: 2 Jahre Garantie (bis zu 5 Jahre), 24/7 Online-Support, lokale Techniker verfügbar.

- Boss Laser: 2 Jahre Garantie, U.S.-amerikanischer Support, Mon-Fri 9 am5 pm5pm EST.

Tipp: Prüfen Sie vor dem Kauf immer die Garantie- und Supportzeiten. Schnelle und gute Hilfe kann Ihnen Zeit und Geld sparen.

Vielseitigkeit

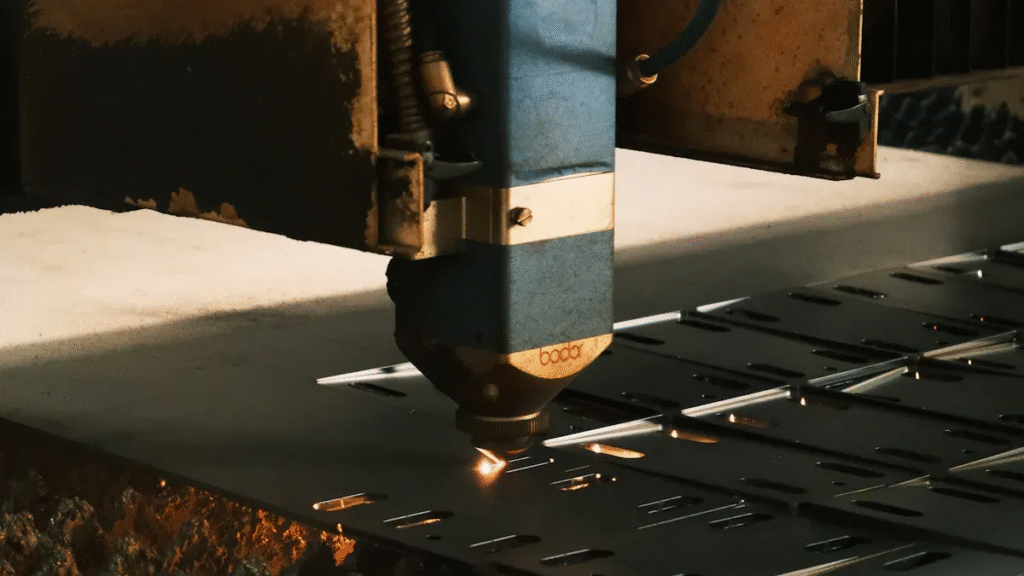

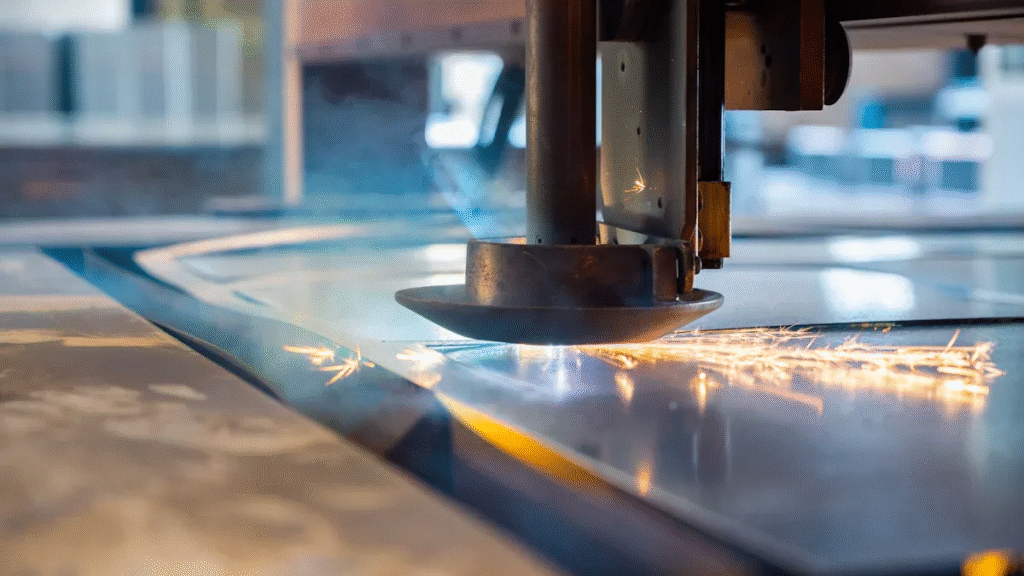

Sie möchten, dass Ihre CO2-Laserquelle mit vielen Materialien arbeiten kann. CO2-Laser können Holz, Kunststoffe, Textilien und einige Metalle schneiden.. Damit können Sie viele verschiedene Arbeiten und Projekte durchführen. Sie können die Einstellungen für jedes Material ändern, um die besten Ergebnisse zu erzielen.

Vielseitigkeit bedeutet, dass Sie ein Gerät für viele Dinge verwenden können. Sie können mit ein und demselben System schneiden, gravieren und markieren. Das spart Platz und senkt die Kosten. Wenn Sie sich für eine CO2-Laserquelle entscheiden, achten Sie darauf, dass sie mit den Materialien funktioniert, die Sie am häufigsten verwenden. So erhalten Sie den besten Wert für Ihr Geld.

Eigenschaften

Rohr-Technologie

Sie möchten, dass Ihre CO2-Laserquelle eine gute Röhrentechnik. Die meisten Top-Systeme verwenden RF-Metall- oder Keramikröhren. Diese Röhren halten länger als Glasröhren. Sie funktionieren auch besser und gehen seltener kaputt. Mit diesen Röhren erhalten Sie eine kleinere Punktgröße. Das bedeutet, dass Sie feinere Schnitte und Markierungen machen können. Die folgende Tabelle zeigt, wie sich RF-Metall- und Keramikröhren von Glasröhren unterscheiden:

| Merkmal | RF Metall/Keramik-Röhren | Glas (DC) Röhren |

|---|---|---|

| Gebrauchstauglichkeit | Längere Garantien, wiederaufladbar | Eingeschränkte Wartungsfähigkeit |

| Langlebigkeit | Langlebiger, besserer Widerstand | Weniger haltbar |

| Lebenserwartung | Wesentlich längere Betriebsdauer | Kürzere Lebenserwartung |

| Pulsfrequenz | Höhere Pulsfrequenz, schnellere Gravur | Begrenzte Pulsfrequenz |

| Spot Größe | Kleinere Spotgröße, feinere Details | Größere Spotgröße |

| Kosten | Teurer | Kostengünstiger |

RF-Metall- oder Keramikröhren liefern bessere Ergebnisse. Sie gehen auch seltener kaputt. Auf diese Röhren wird eine längere Garantie gewährt. Das gibt Ihnen ein sicheres Gefühl für Ihr Gerät.

Strom-Optionen

Sie müssen Wählen Sie die richtige Energie für Ihren Auftrag. CO2-Laser können eine niedrige oder hohe Leistung haben. Dünne Materialien benötigen weniger Leistung zum Schneiden. Dickere Materialien benötigen mehr Leistung zum Schneiden. Mehr Leistung bedeutet bessere Schnitte und schnelleres Arbeiten. Wenn Sie viele Aufträge erledigen, spart eine hohe Leistung Zeit und Geld. Laser mit geringer Leistung sind gut für kleine Aufträge. Sie kosten weniger. Passen Sie die Leistung an Ihre Bedürfnisse an, um beste Ergebnisse zu erzielen.

- Dünnere Materialien: geringere Leistung

- Dickere Materialien: höhere Macht

- Aufträge mit hohem Volumen: höhere Leistung verbessert die Effizienz

- Aufträge mit geringem Volumen: weniger Strom spart Kosten

- Höhere Leistung: bessere Qualität, höherer Energieverbrauch

Automatisierung

Automatisierung hilft Ihnen, schneller zu arbeiten und weniger Fehler zu machen. Viele CO2-Laserquellen verwenden Kameras, um die Teile zu platzieren. Sie können die Teile in jede beliebige Richtung platzieren und erhalten trotzdem gute Markierungen. Intelligente Computerprogramme steuern den Laser und sorgen für Genauigkeit. Sie können Produkte schnell markieren und mit Ihrer Arbeit Schritt halten. Die Tabelle unten zeigt wichtige Automatisierungsfunktionen:

| Merkmal | Beschreibung |

|---|---|

| Flexible Positionierung | Platzieren Sie Werkstücke in beliebiger Ausrichtung, keine Vorrichtungen erforderlich |

| Präzise Algorithmen | Fehler minimieren, konsistente Qualität sicherstellen |

| Nahtlose Integration | Arbeitet mit automatisierten Prozessen für Echtzeit-Kennzeichnung |

| Hohe Auflösung | Positioniergenauigkeit bis zu 0,02 mm |

Sie erhalten jedes Mal sehr genaue Markierungen. Die Automatisierung ist hilfreich bei schwierigen Aufgaben oder detaillierten Mustern.

Sicherheit

Sicherheit ist an jedem Arbeitsplatz wichtig. Gute CO2-Laserquellensysteme haben viele Sicherheitsfunktionen. Sicherheitsverriegelungen stoppen den Laser, wenn sich die Tür öffnet. Feuerlöscher und Belüftungssysteme sorgen für die Sicherheit des Bereichs. Die Arbeiter müssen bei Bedarf Schutzkleidung tragen. Warnschilder erinnern Sie an die Gefahren des Lasers. Verbundsicherheitsglas schützt Ihre Augen, während Sie zusehen. Ein sauberer Arbeitsplatz und der richtige Umgang mit den Materialien verringern die Risiken.

| Sicherheitsmerkmal | Beschreibung |

|---|---|

| Sicherheitsverriegelungen | Der Laser stoppt, wenn sich die Buchttür öffnet |

| Feuerlöscher | CO2/ABC-Feuerlöscher in der Nähe |

| Aktive Belüftungssysteme | Entfernt giftige Dämpfe |

| Persönliche Schutzausrüstung | Erforderlich für Betreiber |

| Warnhinweise | Warnungen vor Strahlungsgefahren |

| Verbundsicherheitsglas | Blockiert CO2-Laserstrahlung |

| Arbeitsbereich löschen | Reduziert das Unfallrisiko |

| Material Handling | Sichere Lagerung und Handhabung |

Tipp: Nur geschulte Personen sollten das Lasergerät benutzen. Schneiden Sie keine glänzenden Materialien. Halten Sie brennbare Gegenstände vom System fern.

Materialien & Anwendungen

Unterstützte Materialien

A CO2-Laserquelle funktioniert mit vielen Materialien. Das macht ihn für viele Aufgaben nützlich. Sie verwenden Materialien, die die Laserenergie gut aufnehmen können. Einige Beispiele sind Glas, Kunststoff und Holz. Sie können auch schneiden und Metalle und Kunststoffe gravieren. Hier sind einige Materialien, die Sie verwenden können:

- Holz

- Hartfaserplatte

- Schaumstoff

- Filz

- Messing

- Leder

- Aluminium

- Gummi

- Papier

- Plastik

- Kohlenstoffstahl

- Kork

- Kohlefaser

- Stoff

- Rostfreier Stahl

Sie müssen Ihre Einstellungen für jedes Material ändern. Glänzende Metalle erfordern besondere Leistungseinstellungen. Einige Kunststoffe können schmelzen, wenn Sie zu viel Strom verwenden. Keramik muss vorsichtig behandelt werden, damit sie nicht reißt. Sie erzielen bessere Ergebnisse, wenn Sie die Einstellungen auf das Material abstimmen.

Tipp: Testen Sie Ihr Material, bevor Sie einen großen Auftrag beginnen. So können Sie Fehler vermeiden und gute Ergebnisse erzielen.

Industrielle Nutzungen

Sie verwenden eine CO2-Laserquelle für viele Arbeiten. Sie können schneiden, markieren, gravieren, ritzen und schlitzen Dinge. Jede Aufgabe erfordert andere Einstellungen und Arbeitsweisen. Sie können auch Oberflächen reinigen und Texturen hinzufügen. Sie gravieren Metalle, Kunststoffe, Holz, Leder und Keramiken. Sie machen matte Designs auf Glas. Sie können Logos und Seriennummern auf Elektronik anbringen. Sie gravieren Barcodes und QR-Codes zur Nachverfolgung. Sie können Auszeichnungen und Trophäen personalisieren. Sie verzieren auch Stoffe und Textilien.

Hier ist eine Tabelle, die zeigt, wie sich Gravur und Rillen unterscheiden:

| Anwendungstyp | Beschreibung | Wichtige Einstellungen |

|---|---|---|

| Gravur | Nimmt Material weg und macht eine Vertiefung. | Ändern Sie Kraft und Geschwindigkeit für tiefere Spuren. |

| Scoring | Erzeugt eine dünne Linie, schneidet aber nicht ganz durch. | Verwenden Sie eine niedrige Leistung für eine flache Rille. |

Sie wählen den richtigen Job für das, was Sie brauchen. Sie erzielen gute Ergebnisse, wenn Sie Ihre Maschine richtig einstellen.

Auswahl einer CO2-Laserquelle

Bedarfsanalyse

Sie sollten wissen, was Sie brauchen, bevor Sie sich für eine CO2-Laserquelle entscheiden. Denken Sie an die Materialien, die Sie verwenden und wie dick diese sind. Sie müssen auch wissen, wie genau Ihre Schnitte sein müssen. Auch die Geschwindigkeit spielt eine Rolle. Entscheiden Sie also, wie schnell Sie jeden Auftrag erledigen wollen. Die Leistung des Geräts ist für Ihre Aufgaben wichtig. Das Steuerungssystem kann Ihnen helfen, schneller und einfacher zu arbeiten. Ein guter Service nach dem Kauf sorgt dafür, dass Ihre Maschine über Jahre hinweg gut funktioniert. In der folgenden Tabelle sind die Dinge aufgeführt, an die Sie denken sollten:

| Faktor | Beschreibung |

|---|---|

| Anpassung von Material und Dicke | Finden Sie heraus, welche Materialien Sie am häufigsten verwenden, und wählen Sie die richtige Laserleistung zum Schneiden. |

| Schnittgenauigkeit und Geschwindigkeit | Entscheiden Sie, wie genau und schnell Sie für Ihre Arbeit schneiden müssen. |

| Leistung und Effizienz der Ausrüstung | Wählen Sie eine Leistungsstufe, die gut funktioniert und weder Energie noch Geld verschwendet. |

| Kontrollsystem | Suchen Sie nach intelligenten Kontrollsystemen, die die Arbeit einfacher und schneller machen. |

| Service nach dem Kauf | Prüfen Sie, ob das Unternehmen gute Hilfe und Unterstützung für Ihr Gerät bietet. |

| Kostenüberlegungen | Überlegen Sie, wie viel die Maschine jetzt und später kostet. |

Passen Sie die Laserleistung an die Materialien an, die Sie am häufigsten verwenden. Metalle wie Aluminium und Kupfer benötigen mehr Energie weil sie Licht reflektieren und bei hohen Temperaturen schmelzen. Holz und Acryl benötigen weniger Strom, aber Sie müssen aufpassen, dass sie nicht verbrennen. Dicke Materialien benötigen mehr Strom, aber dünne Materialien können weniger Strom verbrauchen.

- Metallische Materialien: Benötigen mehr Laserleistung.

- Nicht-metallische Materialien: Verwenden Sie weniger Energie, aber achten Sie auf Verbrennungen.

- Materialstärke: Dickere Materialien benötigen mehr Leistung.

Kosten & ROI

Sie möchten, dass Ihr Geld weit reicht, wenn Sie eine CO2-Laserquelle kaufen. Der Preis beinhaltet das, was Sie zuerst bezahlen und was Sie im Laufe der Zeit bezahlen. Achten Sie darauf, wie lange die Garantie dauert und wie gut der Support ist. Eine gute Garantie spart Ihnen Geld, wenn etwas kaputt geht. Die meisten Unternehmen gewähren eine 12-monatige Garantie auf Teile und eine 2-jährige Garantie auf die Laserquelle.. Kostenlose Ersatzteile während der Garantiezeit helfen Ihnen, zusätzliche Kosten zu vermeiden. Die folgende Tabelle zeigt, wie sich Garantie und Support auf Ihre Gesamtkosten auswirken:

| Faktor | Auswirkungen auf die Gesamtbetriebskosten (TCO) |

|---|---|

| Dauer der Garantie | Ändert, wie viel Sie für Reparaturen bezahlen und wie zuverlässig der Laser ist. |

| Technische Unterstützung | Beeinflusst, wie viel Sie für die Reparatur und den Betrieb der Maschine ausgeben. |

- Eine gute Garantie hilft Ihnen, überraschende Reparaturrechnungen zu vermeiden.

- Solange die Garantie läuft, erhalten Sie kostenlose Ersatzteile.

Denken Sie daran, wie viel Energie das Gerät verbraucht und wie oft Sie es reparieren müssen. Hochleistungslaser sind teurer im Betrieb, aber sie erledigen Aufträge schneller und leisten mehr Arbeit. Wenn Sie das Gerät viele Jahre lang nutzen möchten, helfen Ihnen ein starker Support und eine lange Garantie, Geld zu sparen.

Sicherheitsstandards

Ihre CO2-Laserquelle muss den Sicherheitsvorschriften entsprechen. Die führenden Marken befolgen die Regeln von Gruppen wie ANSI, OSHA, FDA und IEC. Diese Gruppen stellen Regeln für die sichere Verwendung in Schulen, Krankenhäusern und Fabriken auf. In der folgenden Tabelle finden Sie eine Liste der wichtigsten Regelmacher:

| Regulierungsbehörde | Beschreibung |

|---|---|

| ANSI | Erstellt Lasersicherheitsvorschriften für Militär, Medizin, Schulen und Fabriken (ANSI Z136-Serie). |

| OSHA | Legt Regeln für die sichere Verwendung von Lasern bei der Arbeit fest. |

| FDA | Prüft Laserprodukte in den USA, insbesondere für den medizinischen und geschäftlichen Gebrauch. |

| IEC | Macht globale Laser-Sicherheitsregeln (IEC 60825). |

Unternehmen zeigen, dass sie die Vorschriften einhalten, indem sie ihre Produkte mit dem CE-Zeichen kennzeichnen. Vergewissern Sie sich, dass Ihr Gerät die EN 60825-1 für Laser und die EN 60825-2 für faseroptische Laser erfüllt. Achten Sie immer auf den Nachweis, dass das Gerät diese Vorschriften einhält. So bleibt Ihr Arbeitsplatz sicher und Sie können Ärger vermeiden.

Tipp: Fragen Sie vor dem Kauf nach Sicherheitspapieren. Vergewissern Sie sich, dass die Maschine mit Warnhinweisen und Sicherheitssperren versehen ist.

Unterstützen Sie

Sie brauchen gute Hilfe und schnellen Service, damit Ihre CO2-Laserquelle gut funktioniert. Die besten Unternehmen haben große Teams, die den Kunden helfen. Unternehmen mit mehr als 80 Mitarbeitern können Ihnen besser helfen. Schnelle Antworten, meist in weniger als einer Stunde, bedeuten, dass Sie schnell Hilfe bekommen. Wählen Sie Marken mit mindestens fünf Jahren Erfahrung für einen guten Service. Die folgende Tabelle zeigt, worauf Sie achten sollten:

| Beweismittel Typ | Beschreibung |

|---|---|

| Technische Unterstützung | Unternehmen mit 80+ Mitarbeitern können starke technische Hilfe leisten. |

| Service-Verfügbarkeit | Unternehmen mit einer Reaktionszeit von weniger als einer Stunde bieten schnelle Hilfe. |

| Operative Geschichte | Wählen Sie Unternehmen, die seit fünf oder mehr Jahren tätig sind, um Stabilität zu gewährleisten. |

Lebenslange Hilfe gibt Ihnen Seelenfrieden. Sie können jederzeit Hilfe erhalten, um Ihr Gerät zu reparieren und funktionsfähig zu halten. Die Hilfe erfolgt per Telefon, E-Mail oder über Apps wie WhatsApp. So können Sie das Beste aus Ihrem Gerät herausholen.

Hinweis: Gute Hilfe und guter Service erleichtern Ihnen die Arbeit und schützen Ihr Geld.

Eine hochwertige CO2-Laserquelle hat eine starke Leistung. Sie schneidet schnell und macht präzise Markierungen. Die Tabelle unten zeigt diese Eigenschaften:

| Wichtigste Spezifikation | Beschreibung |

|---|---|

| Leistung | 20W bis mehrere kW, für viele Anwendungen geeignet |

| Schnittgeschwindigkeit | Hochgeschwindigkeitsschneiden für dünne Materialien |

| Strahlqualität (M²) | Feine Schnitte und Markierungen |

| Methode der Kühlung | Die Wasserkühlung hält das System stabil |

| Wellenlänge | 10,6 Mikrometer, ideal für Nicht-Metalle und einige Metalle |

Die Auswahl der richtigen Funktionen hilft Ihnen, schneller zu arbeiten. Es bedeutet auch, dass Sie weniger von Hand machen. Sie sollten Experten um Rat fragen. Sie wissen, welche Maschine für Ihre Materialien am besten geeignet ist. Experten helfen Ihnen, ein gutes Gleichgewicht zwischen Kosten und Leistung zu finden. Sie informieren Sie auch über neue Trends in der Branche.

- Experten helfen Ihnen bei der Auswahl der besten Maschine für Ihre Materialien

- Sie geben Ratschläge zu Kosten und Funktionsweise

- Sie informieren Sie über Neuigkeiten in der Branche

Sprechen Sie mit Anbietern oder bitten Sie um eine Vorführung. So finden Sie das beste Gerät für Ihr Unternehmen.

FAQ

Welche Materialien können Sie mit einer CO2-Laserquelle schneiden oder gravieren?

Sie können einen CO2-Laser verwenden, um geschnittenes Holz, Acryl und Leder. Es funktioniert auch auf Glas, Papier, Gummi und einigen Kunststoffen. Sie können auch beschichtete Metalle beschriften. Stellen Sie immer sicher, dass Ihr Material mit Ihrem Lasersystem kompatibel ist.

Wie oft sollten Sie Ihre CO2-Laserquelle warten?

Reinigen Sie die Optik jede Woche. Überprüfen Sie das Kühlsystem einmal im Monat. Wechseln Sie bei Bedarf die Filter. Regelmäßige Pflege hilft Ihrem Gerät, länger zu halten und gut zu funktionieren.

Welche Sicherheitsausrüstung benötigen Sie beim Betrieb eines CO2-Lasers?

Tragen Sie immer eine Laserschutzbrille. Halten Sie Ihren Arbeitsbereich sauber und aufgeräumt. Sorgen Sie für eine gute Belüftung, um die Dämpfe loszuwerden. Befolgen Sie alle Sicherheitshinweise im Handbuch Ihres Geräts.

Wie wählen Sie die richtige Leistungsstufe für Ihre Anwendung?

| Material Dicke | Empfohlene Leistung (W) |

|---|---|

| Dünn (≤3mm) | 30-60 |

| Mittel (4-8mm) | 60-100 |

| Dick (≥10mm) | 100+ |

Wählen Sie eine Leistungsstufe, die zu Ihrem Material und der Größe des Auftrags passt. So erzielen Sie die besten Ergebnisse.