You use a CO2 laser tube when you need strong and exact laser power. It helps with cutting, engraving, marking, and some medical treatments. This tool is the most common in laser machines. People like it because it works well and is dependable. Glass, RF/metal, and ceramic tubes each have special strengths. You can use it on many materials. These include wood, acrylic, plastics, foam, leather, and fabric.

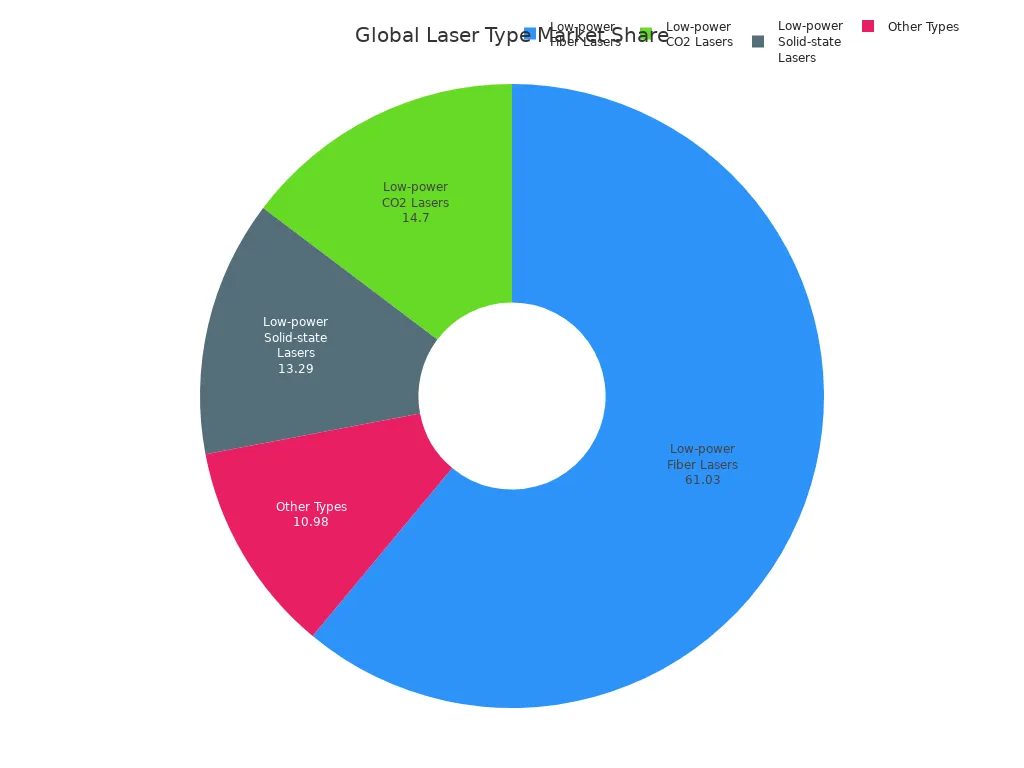

| Laser Type | Market Share (%) |

|---|---|

| Low-power Fiber Lasers | 61.03 |

| Low-power CO2 Lasers | 14.70 |

| Low-power Solid-state Lasers | 13.29 |

| Other Types | 10.98 |

- Wood

- Acrylic (Plexiglass, Lucite, PMMA)

- Plastics

- Foam

- Leather

- Fabric

Key Takeaways

- CO2 laser tubes can do many things. They cut, engrave, mark, and help in medical work. They work well on wood, acrylic, and leather.

- There are different CO2 laser tubes. Glass tubes cost less but are not very exact. RF/metal tubes are very accurate and strong. Ceramic tubes are good and not too expensive.

- Pick a CO2 laser tube based on your material. Think about how much detail you need. This helps you get the best results.

- You need to take care of CO2 laser tubes. Glass tubes need more care. RF/metal and ceramic tubes are easier to look after and last longer.

- CO2 laser tubes help many industries work better. They give clean and exact results in factories and hospitals.

CO2 laser tube applications

Cutting

A CO2 laser tube cuts things fast and neatly. Many businesses use it to shape parts. You find it in making musical instruments, furniture, clothes, ads, models, leather, art, printing, toys, bags, and curtains.

- Musical instrument industry

- Furniture industry

- Garment industry

- Advertising industry

- Model production industry

- Leather processing industry

- Art industry

- Printing and packaging industry

- Children’s toy production industry

- Luggage production industry

- Curtain production industry

You can cut thick or thin acrylic and wood. The table shows how thick or thin you can cut:

| Material | Maximum Thickness (mm) | Minimum Thickness (mm) |

|---|---|---|

| Acrylic | 25 | 1 |

| Wood | 20 | 1 |

A CO2 laser tube makes smooth edges and less waste. You can also cut plastics, foam, and fabric with good results.

Engraving

A CO2 laser tube engraves designs and words on many things. This lets you make products special and create signs. You can engrave glass, metal, wood, plastic, paper, leather, ceramic, acrylic, fabric, electronics, barcodes, medical tools, awards, and accessories.

- Glassware

- Metal Items

- Wooden Products

- Plastic Items

- Paper and Cardstock

- Leather Goods

- Ceramic Tiles

- Acrylic Products

- Fabric and Textiles

- Electronics and Gadgets

- Barcodes and QR Codes

- Medical Instruments

- Awards and Trophies

- Personal Accessories

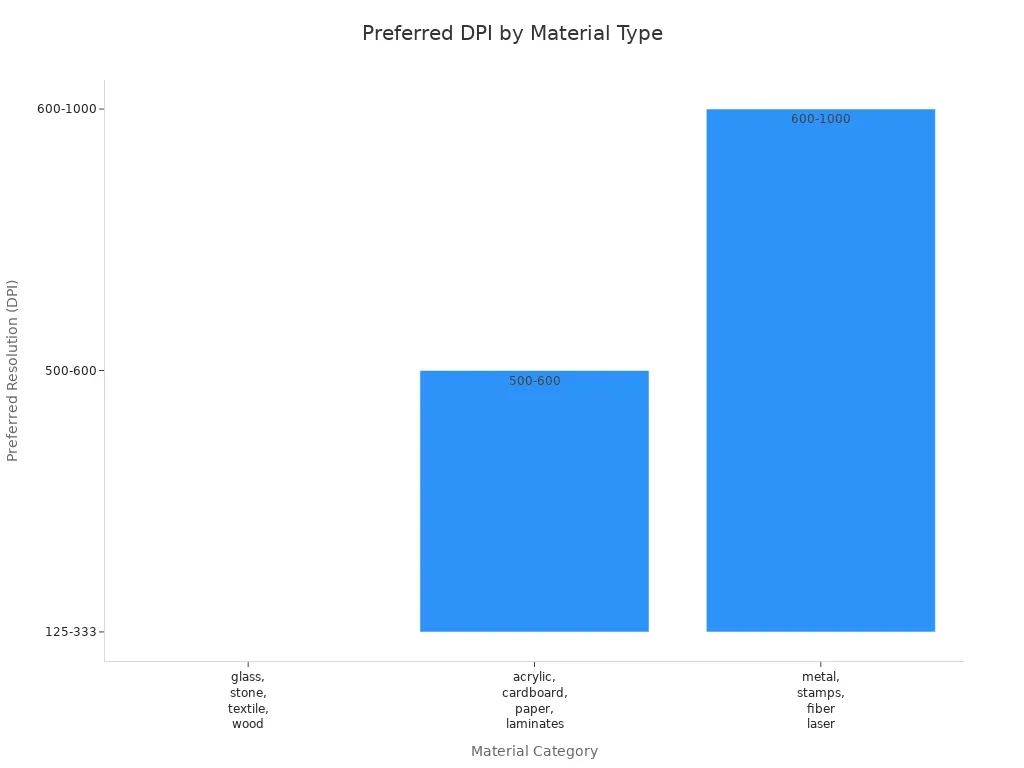

You get different detail levels for each material. The table shows which settings work best:

| Material used | Preferred resolutions |

|---|---|

| glass, stone, textile, wood | lower resolutions: 125, 250, and 333 dpi |

| acrylic, cardboard, paper, laminates | moderate resolutions: from 500 to 600 dpi |

| metal, stamps, processing with fiber laser | Higher resolutions: from 600 to 1000 dpi |

You get sharp pictures and clear words with the right settings. A CO2 laser tube helps you make things look professional.

Marking and welding

A CO2 laser tube marks products so you can tell them apart. You can add numbers, logos, and codes to metal, plastic, and glass. This helps you keep track of items and stop fake ones. You can also weld thin materials with a CO2 laser tube. The laser joins pieces without extra stuff. You get strong, clean welds and little heat damage.

Tip: You can mark barcodes and QR codes on electronics and medical tools for easy scanning and tracking.

Medical uses

Doctors use CO2 laser tubes for many medical jobs. They help with scars, women’s health, and ear, nose, and throat surgeries. The table lists common uses and what they do:

| Medical Procedure | Description |

|---|---|

| Hypertrophic Scar Revision | CO2 lasers remove deep scar tissue and help skin look better. |

| Minimally Invasive Gynecological | Used for problems like vaginal atrophy and cervical dysplasia, giving exact tissue removal. |

| ENT Surgery | Used for throat surgeries and sleep apnea treatment. |

| Laryngeal Surgeries | Treats vocal cord problems with careful cutting. |

| Oral Cavity Tumors | CO2 lasers remove tumors in the mouth and vocal cords. |

| Benign Laryngeal Pathology | Used for harmless growths, letting doctors cut carefully and not too deeply. |

| Phonosurgical Procedures | CO2 lasers remove early vocal cord tumors. |

CO2 laser tube treatments work well most of the time. The table shows what usually happens:

| Outcome Description | Result |

|---|---|

| Incidence of after-treatment keloids | ~1% |

| Recurrence of viral lesions | Not more often than other ways |

| Tumor recurrence compared to other methods | Less than with radiation or surgery |

| Healing time | Shorter |

| Need for anaesthesia | Not needed much |

| Thermal damage | Less |

| Bleeding | Less |

| Inflammation | Less |

You heal faster, bleed less, and have fewer problems. A CO2 laser tube gives doctors good control and safer results in surgery and skin care.

CO2 laser tube types

Glass tubes

Glass tubes are used in beginner laser machines. These tubes have a glass chamber with gas inside. Water cools the tube while it works. Glass tubes are good for basic cutting and engraving. They cost less than other tube types. You can use them for simple projects. They are not great for jobs needing high accuracy.

- Glass tubes are best for:

- Hobby projects

- Simple signs

- Cutting acrylic and wood

The spot size is about 0.25mm. You might see less accuracy and lower beam quality. Glass tubes last about 2,500 hours. You need to replace them more often. The power supply uses high voltage. This can make the tube less stable.

Note: Glass tubes break easily. Be careful when you handle them.

| Feature | Glass Tube |

|---|---|

| Service Life | About 2,500 hours need replacing |

| Cooling Method | Water cooling can have problems |

| Spot Size | 0.25mm, not very accurate |

| Stability | High-voltage power, not always stable |

| Price | Cheaper, good for some products |

| Beam Quality | Lower quality, not for fine engraving |

| Durability | Breaks easily, does not last long |

| Maintenance | Short warranty, needs replacing often |

| Precision Level | Medium precision (can upgrade with HR lens) |

RF/metal tubes

RF/metal tubes are used in professional laser machines. These tubes have metal chambers and use radio frequency power. Air cools the tube, so it works steadily. RF/metal tubes give high precision and great beam quality. The spot size is about 0.07mm. You can engrave tiny details and cut sharp edges.

- RF/metal tubes are best for:

- Industrial engraving

- Marking electronics

- Making medical devices

RF/metal tubes last over 45,000 hours. You do not need to replace them often. The power supply uses low voltage. This makes the tube stable and safe. They cost more money, but you get reliable results and less work fixing them.

| Feature | RF/Metal Tube |

|---|---|

| Service Life | Over 45,000 hours, can reuse |

| Cooling Method | Air cooling works well |

| Spot Size | 0.07mm, very accurate |

| Stability | Low-voltage power, very stable |

| Price | Expensive, gives high-quality results |

| Beam Quality | Great beam quality, proven tech |

| Durability | Strong, lasts a long time |

| Maintenance | Needs little fixing |

| Precision Level | Very high precision |

Ceramic tubes

Ceramic tubes are between glass and RF/metal tubes. These tubes have a ceramic chamber. They give good beam quality and steady performance. Ceramic tubes last longer than glass tubes. They need less fixing. You can use them for cutting and engraving.

- Ceramic tubes are best for:

- Small business work

- Detailed engraving

- Cutting thin metals and plastics

Ceramic tubes are strong and need little fixing. The beam quality is close to RF/metal tubes. The tube works well for many jobs and materials.

| Feature | Ceramic Tube |

|---|---|

| Service Life | Lasts a long time |

| Cooling Method | Air or water cooling |

| Spot Size | Small, pretty accurate |

| Stability | Works steadily |

| Price | Costs a medium amount |

| Beam Quality | Like RF/Metal, good quality |

| Durability | Strong |

| Maintenance | Needs little fixing |

| Precision Level | Very accurate |

Tip: Pick the tube type that fits your job. Glass tubes are good for easy tasks. RF/metal tubes are best for precise work. Ceramic tubes are a good choice for both quality and price.

Type comparison

Performance

You want strong power and steady results from your CO2 laser tube. Glass tubes work well for cutting and engraving non-metal things. Their power drops fast after some use. RF/metal tubes give high power and stay stable. They are great for big jobs in factories. Ceramic tubes use special gas mixes. This helps them keep power steady and not get too hot.

| Type of CO2 Laser Tube | Power Output | Stability |

|---|---|---|

| Glass CO2 Laser Tube | Not easy to adjust, short life | Gets too hot, not stable |

| Metal CO2 Laser Tube | High power, works well | Very reliable |

| Ceramic CO2 Laser Tube | Power stays steady | Not much heat, works smoothly |

Tip: RF/metal tubes are best for sharp details and speed. Glass tubes are good for simple jobs.

Lifespan

You want your laser tube to last a long time. Glass tubes work for 1,500 to 3,000 hours. RF/metal tubes can last six years or more. Some work up to 20,000 hours. Ceramic tubes last longer than glass tubes. You can adjust them to get full power again.

- Glass tubes: 1,500–3,000 hours

- RF/metal tubes: Six years, up to 20,000 hours

- Ceramic tubes: Last long, power can be fixed

| Factor | Description |

|---|---|

| Temperature | Keep tubes cool to make them last. |

| Humidity | Dry air helps tubes work longer. |

| Air Quality | Clean rooms stop damage. |

| Cooling System Effectiveness | Good cooling stops tubes from getting too hot. |

| Working Hours | Short breaks help tubes last longer. |

| Regular Maintenance | Clean and check tubes often. |

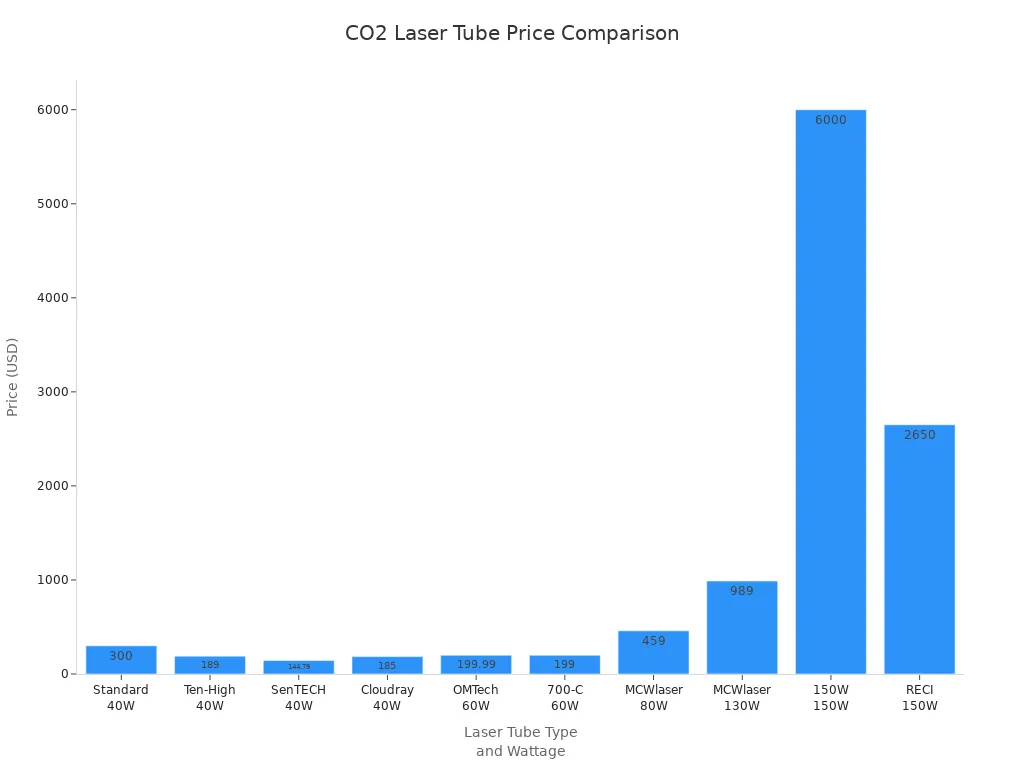

Cost

Cost is important for every project. Glass tubes cost less at first. Prices start at $150 for 40W tubes. RF/metal tubes cost a lot more. Sometimes they cost as much as the whole machine. You save money on repairs with RF/metal tubes. Ceramic tubes cost somewhere in the middle.

| Laser Tube Type | Initial Cost | Long-term Cost |

|---|---|---|

| RF Laser Tubes | Higher | Lower |

| Glass Laser Tubes | Lower | Higher |

Note: Glass tubes are cheap for beginners. RF/metal tubes cost more but last longer.

Maintenance

You need to keep your laser tube clean and cool. Glass tubes need lots of water checks and cleaning. You have to clean them often. RF/metal tubes need less care and break less. Ceramic tubes are easy to take care of. They work well in clean places.

| Laser Tube Type | Maintenance Costs | Downtime | Lifespan |

|---|---|---|---|

| RF Laser | Low | Little | 5-7 years |

| Glass Tube | High | Often | 6-12 months |

- Glass tubes: Check water, clean a lot, replace more.

- RF/metal tubes: Less cleaning, fewer repairs.

- Ceramic tubes: Easy care, works steadily.

If you want less work and more use, pick RF/metal or ceramic tubes. Glass tubes need more care and replacing.

CO2 laser tubes let you cut, engrave, and mark lots of things. You can pick glass, metal RF, or ceramic tubes. Each one is good for certain jobs and budgets.

| CO2 Laser Tube Type | Key Characteristics | Best Use Cases |

|---|---|---|

| Glass Tube | Costs less to start, not great for tiny details at low power | Good for short projects and small jobs |

| Metal Tube RF | Controls power better, might not work as well after a while | Works for medium jobs and faster work |

| Ceramic RF | Makes a steady, clean beam and lasts a long time | Best for important jobs and big factories |

When you choose a tube, remember these things:

- What you want to do changes how much power you need.

- Make sure your tube works with your material.

- How much you spend changes how long your tube lasts and how well it works.

You get the best results when your tube fits your project. If you know what each type does well and not so well, you can pick better and save money over time.

FAQ

What materials can you cut with a CO2 laser tube?

You can cut acrylic, wood, leather, fabric, paper, and some plastics. You should not use it for thick metals. Always check the material type before starting your project.

How long does a CO2 laser tube last?

Most glass tubes last 1,500–3,000 hours. RF/metal tubes work for over 20,000 hours. Ceramic tubes last longer than glass tubes. You should check your tube’s hours to plan replacements.

Do you need special cooling for a CO2 laser tube?

Glass tubes need water cooling. RF/metal and ceramic tubes use air cooling. You must keep your cooling system clean to avoid damage and keep your tube working well.

Can you engrave photos with a CO2 laser tube?

Yes, you can engrave photos on wood, acrylic, glass, and leather. You should use higher DPI settings for better detail. Always test your settings before starting your final project.

Is a CO2 laser tube safe to use?

You must wear safety glasses and keep the area clear. Never look directly at the laser beam. Always follow your machine’s safety instructions to protect yourself and others.