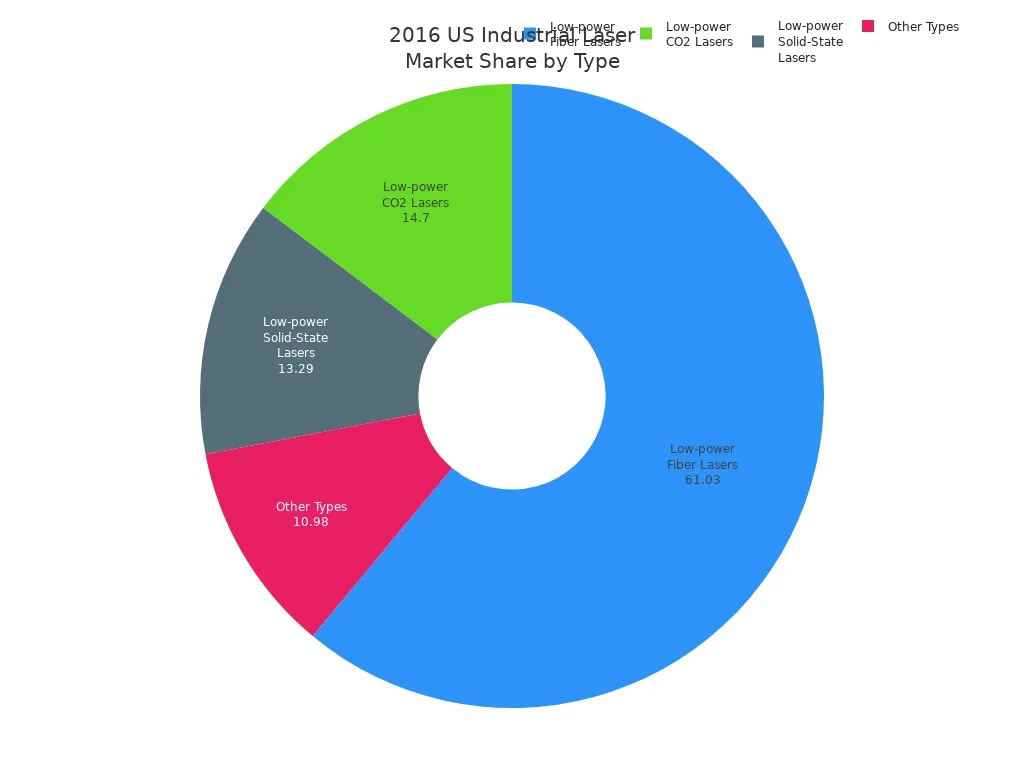

A CO2 laser tube generates a powerful beam that lets you cut and engrave a wide range of materials with precision. You will find this technology in many industrial machines, especially those used for woodworking, packaging, textiles, and automotive production. The three main types—DC glass, RF metal, and ceramic—offer distinct advantages for different tasks. While fiber lasers lead the market, CO2 laser tubes still account for 14.7% of U.S. industrial laser cutting machines.

| Laser Type | Market Share (2016, US) |

|---|---|

| Low-power Fiber Lasers | 61.03% |

| Low-power CO2 Lasers | 14.70% |

| Low-power Solid-State Lasers | 13.29% |

| Other Types | 10.98% |

Key Takeaways

- A CO2 laser tube produces a strong laser beam used to cut and engrave many materials with high precision.

- There are three main types of CO2 laser tubes: DC glass, RF metal, and ceramic, each with different costs, durability, and performance.

- CO2 laser tubes work by exciting a gas mixture inside a sealed tube, creating photons that bounce between mirrors to form a powerful laser beam.

- Choosing the right tube depends on your material, power needs, machine compatibility, and budget.

- Proper cooling, usually water or air, is essential to keep the laser tube from overheating and to extend its lifespan.

- Regular maintenance like cleaning mirrors, checking alignment, and monitoring cooling systems helps prevent damage and keeps the laser working well.

- Safety is critical when using CO2 lasers; always follow guidelines, wear protective gear, and never disable safety features.

- Upgrading or replacing a CO2 laser tube requires careful matching of size, power, and connectors to your machine to ensure safe and effective operation.

CO2 Laser Tube Basics

Definition

You encounter a CO2 laser tube as the heart of many laser cutting and engraving machines. This device generates a concentrated beam of light by exciting a gas mixture—usually carbon dioxide, nitrogen, and helium—inside a sealed glass or metal tube. When you activate the system, an electrical discharge energizes the gas molecules. These molecules release photons, which bounce between mirrors inside the tube. The process amplifies the light and produces a powerful laser beam. The quality and power of the CO2 laser tube determine how precisely you can cut or engrave materials.

Tip: The performance of your laser machine depends heavily on the condition and specifications of the CO2 laser tube you choose.

Main Uses

You find CO2 laser tubes in a wide range of industries and small businesses. Their versatility makes them popular for both mass production and custom projects. Common applications include:

- Musical instrument manufacturing, where you cut wood panels and engrave artistic patterns on guitars or violins.

- Furniture production aallowsyou to efficiently cut wood boards for doors, tables, and chairs.

- The garment industry eenableshigh-precision fabric cutting without damaging single or multi-layer materials.

- Advertising, helping you cut and engrave acrylic materials with smooth edges and distinctive finishes.

- Model production, letting you cut complex shapes in thin sheets like acrylic for architectural models.

- Leather processing, where you cut and engrave patterns on bags, belts, and shoes with minimal deformation.

- ArThe artndustry, supports the creation of gifts, intricate patterns, and artwork from wood and acrylic.

You also see CO2 laser tubes used in printing and packaging, toy production, luggage, and curtain manufacturing. Their ability to deliver clean, precise cuts and engravings makes them essential in these fields.

Key Components

A CO2 laser tube contains several critical parts that work together to generate and deliver the laser beam. Each component plays a specific role in the operation and quality of your laser system.

| Component | Role in Operation |

|---|---|

| Electrodes | Facilitate electrical discharge to excite the gas mixture. |

| Gas Mixture | Produces the laser light when energized. |

| Mirrors | Amplify photons by bouncing them back and forth, forming a resonant cavity. |

| Partially Reflective Mirror | Allows the amplified laser beam to exit the tube. |

| Lenses | Focus the laser beam for precise cutting or engraving. |

| Protective Glass | Shields the lens from debris and vapors, maintaining beam quality and lens lifespan. |

| Height Sensor | Maintains a consistent distance between the nozzle and the material for uniform cuts and protection. |

| Collimation Components | Straighten and focus the laser beam to ensure accurate direction towards the material. |

| Protective Mirror Box | Isolates internal optics from dust and impurities, prolonging cutting head life. |

| Focus Tracking System | Automatically adjusts cutting head height to maintain optimal focus on the workpiece. |

| Auxiliary Gas Nozzle | Directs gas flow to remove molten material, cool the workpiece, and prevent oxidation or combustion. |

| Water Cooling System | Dissipates heat from the laser and optics to prevent overheating and damage. |

| Mechanical Adjustment | Enables precise positioning of the cutting head along the Z-axis for programmed cutting paths. |

| Control Box | Houses electronics and software managing laser operation and cutting parameters. |

| Ceramic Parts | Provide insulation and protection for optical components, ensuring durability under high temperatures. |

| Beam Delivery System | Uses mirrors and lenses to guide and focus the laser beam accurately from the source to the cutting head. |

You rely on these components to achieve consistent results and maintain the longevity of your CO2 laser tube. Regular inspection and maintenance help you avoid downtime and costly repairs.

How It Works

Laser Generation

Gas Mixture

You rely on a precise gas mixture to power a CO2 laser tube. Inside the sealed tube, you find a blend of carbon dioxide, nitrogen, and helium. Sometimes, manufacturers add small amounts of hydrogen or xenon to enhance performance. Each gas plays a unique role in the laser process. Carbon dioxide acts as the main lasing medium, nitrogen helps transfer energy, and helium assists with cooling and energy balance. This combination ensures that your laser system operates efficiently and produces a stable, powerful beam.

Light Amplification

The process of generating a laser beam in a CO2 laser tube follows a series of well-defined steps:

- The sealed tube contains a gas mixture of carbon dioxide, nitrogen, helium, and sometimes hydrogen or xenon.

- When you apply an electrical discharge, electrons excite the nitrogen molecules, causing them to vibrate.

- These excited nitrogen molecules transfer their energy to carbon dioxide molecules through collisions.

- The energized carbon dioxide molecules release infrared photons at wavelengths of 9.6 and 10.6 micrometers.

- Helium atoms help maintain the energy balance by cooling the carbon dioxide molecules after they emit photons.

- Mirrors at both ends of the tube reflect the photons back and forth, amplifying the light and forming a coherent laser beam.

Note: The efficiency of this process depends on the purity of the gas mixture and the quality of the tube’s internal components.

Tube Structure

Electrodes

You find electrodes at both ends of the CO2 laser tube. These electrodes create the electric field needed to excite the gas mixture. When you power the system, the electrodes deliver a high-voltage current that initiates the energy transfer process. The arrangement and material of the electrodes influence the tube’s efficiency and lifespan. Wide, rectangular electrodes with a narrow gap can improve cooling and power density, making your laser system more compact and powerful.

Mirrors

Mirrors play a critical role in shaping and amplifying the laser beam. The tube contains two mirrors: one fully reflective and one partially reflective. The fully reflective mirror bounces photons back into the tube, while the partially reflective mirror allows a portion of the amplified light to exit as the usable laser beam. The design and alignment of these mirrors affect the beam’s quality and stability.

| Structural Feature | Contribution to Efficiency and Performance |

|---|---|

| Sealed glass tube with CO2-N2-He gas mixture | Provides the lasing medium; gas mixture composition affects excitation and energy transfer efficiency. |

| Electrode arrangement | Wide rectangular electrodes with a narrow gap improve cooling efficiency and power density, enabling compact, high-power designs. |

| Gas flow design | Enhances heat dissipation by convection, allowing higher power output and operational stability. |

| Optical cavity design | Spherical mirrors with different radii spread lasing action and maintain a tight output beam, improving beam quality. |

You can choose from different gas flow designs to match your application:

- Sealed-tube lasers use conduction for heat removal, which limits power output.

- Slow axial flow lasers use low-pressure gas along the tube axis for moderate power.

- Fast axial flow lasers increase gas speed and use heat exchangers for higher power.

- Transverse flow designs allow greater gas flow across the beam axis, supporting very high power but with some trade-offs in beam quality.

A well-designed CO2 laser tube structure ensures reliable performance, efficient cooling, and consistent cutting or engraving results.

CO2 Laser Tube Types

When you choose a CO2 laser tube for your machine, you encounter three main types: DC glass tubes, RF metal tubes, and ceramic tubes. Each type offers unique advantages and suits different applications. Understanding their construction, operation, and performance helps you select the best option for your needs.

DC Glass Tubes

DC glass tubes represent the most common and affordable choice for many entry-level and mid-range laser machines. You find these tubes constructed with a glass enclosure and metal electrodes. The direct current (DC) excites the gas mixture inside, producing the laser beam. Water cooling is mandatory to prevent overheating and extend the tube’s lifespan.

Typical applications include cutting and engraving non-metal materials such as wood, acrylic, leather, and fabric. You benefit from lower initial costs and simple maintenance, making these tubes ideal for small businesses and hobbyists. However, glass tubes are fragile and prone to breakage. You should avoid running them at full power continuously. Operating at 80-90% of maximum power and allowing cooling periods between uses helps maximize their service life, which averages 3,000 to 8,000 hours.

Tip: Frequent replacement and regular maintenance keep your DC glass tube performing reliably, but you must plan for downtime and replacement costs.

RF Metal Tubes

RF metal tubes use radio frequency (RF) excitation to generate the laser beam. You see these tubes built with a durable metal enclosure and metal electrodes. Air or water cooling keeps the system stable, and the metal housing resists physical damage better than glass.

You gain several advantages with RF metal tubes. The beam quality is superior, producing a fine, circular, and uniform spot. This precision makes RF tubes perfect for detailed engraving and high-speed cutting. The lifespan reaches up to 20,000 hours, supporting stable long-term use. Maintenance is minimal, and you avoid the need for high voltage or complex water cooling systems.

RF metal tubes suit professional workshops and industrial environments where you demand consistent performance and high accuracy. You pay a higher initial cost, but you benefit from reduced maintenance and fewer replacements.

- Key benefits:

- High engraving quality and speed

- Efficient heat dissipation

- Low maintenance requirements

- Long lifespan

Ceramic Tubes

Ceramic tubes represent the latest advancement in CO2 laser tube technology. You find these tubes constructed with a pure ceramic core fused at high temperature. RF excitation powers the laser, and ceramic electrodes resist corrosion, eliminating gas pollution and leakage.

You experience unmatched durability and stability with ceramic tubes. The lifespan is four to five times longer than glass tubes, and the performance remains stable over time. Maintenance is less frequent, but more complex and costly due to the technical nature of the components. Ceramic tubes handle both air and water cooling, but lower heat conductivity compared to metal tubes means cooling can be more challenging.

Ceramic tubes excel in demanding industrial settings where you require high reliability and minimal downtime. You invest more upfront, but you gain long-term value through reduced replacements and stable operation.

| Feature | DC Glass Tubes | RF Metal Tubes | Ceramic Core Tubes |

|---|---|---|---|

| Construction | Glass enclosure with metal electrodes | Metal enclosure with metal electrodes | Ceramic core fused at high temperature |

| Excitation Method | Direct Current (DC) | Radio Frequency (RF) | Radio Frequency (RF) |

| Cooling | Water-cooled (mandatory) | Air or water-cooled | Air or water-cooled |

| Durability | Fragile, prone to breakage | Durable metal housing, metal electrodes corrode over time | Durable ceramic electrodes, no corrosion |

| Lifespan | Moderate (3,000–8,000 hours) | Longer (10,000–20,000 hours) | Long, more stable performance |

| Maintenance | Frequent, simpler, and cheaper | Less frequent but more complex and costly | Difficult maintenance, higher cost |

| Performance | Lower beam quality, slower pulsing | Higher beam quality, rapid pulsing | High engraving quality and speed |

| Cost | Lower initial cost | Higher initial cost | Higher cost |

Note: When you compare these types, consider your application, budget, and maintenance capabilities. DC glass tubes offer affordability and simplicity, RF metal tubes deliver precision and stability, and ceramic tubes provide unmatched durability and long-term performance.

Power Ratings & Cooling

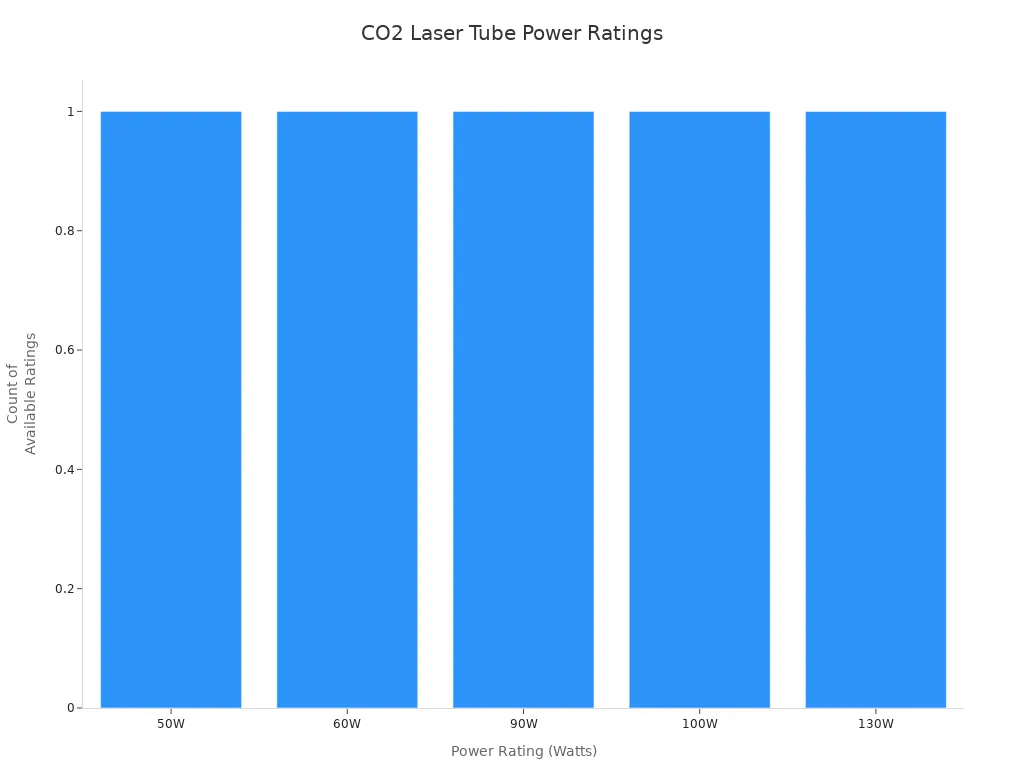

Power Options

When you select a laser tube, you must match its power rating to your application. Power ratings typically range from 20 watts for small desktop units up to 300 watts for industrial machines. Most users work with tubes between 50 and 130 watts. The right power level ensures you achieve clean cuts, fast engraving, and long tube life.

| Power Rating (Watts) | Laser Tube Type | Best Suited Applications |

|---|---|---|

| 50W | DC or RF | Wood cutting and engraving, acrylic and plastic processing, and leather engraving |

| 60W | DC or RF | Slightly higher cutting power, suitable for small to medium projects |

| 90W | DC or RF | Intensive cutting and engraving, metal marking, and etching |

| 100W | DC or RF | Metal cutting, detailed etching, glass etching, and signage |

| 130W | DC or RF | Heavy-duty cutting and engraving, military, aerospace, and industrial use |

Note: RF tubes deliver better beam quality for detailed etching, while DC tubes offer cost savings for general cutting.

You can see the popularity of different power ratings in the chart below:

You should always operate your tube within the recommended current range. For example, a 50W tube may have a maximum current of 21mA. Exceeding this limit can shorten the tube’s lifespan. Most users set their machines to run between 25% and 99% PWM to balance power and longevity.

Cooling Methods

Proper cooling keeps your laser tube running smoothly and extends its life. You can choose between water cooling and air cooling, depending on your tube’s power and your workspace needs.

| Aspect | Water Cooling | Air Cooling |

|---|---|---|

| Cooling Mechanism | Uses liquid coolant to absorb and dissipate heat efficiently | Uses fans to circulate air and dissipate heat less efficiently |

| Cooling Efficiency | High, suitable for all power ranges, especially high-power lasers | Less effective, mainly for low-power lasers (≤100W) |

| Temperature Control | Precise and stable, critical for performance | Less precise, more temperature fluctuations |

| Noise Level | Quieter operation | Noisier due to fans |

| Lifespan Impact | Prolongs tube life by preventing overheating | Shorter lifespan under heavy use |

| Cost and Complexity | Higher needs pumps and chillers | Lower, simpler setup |

| Portability | Less portable, needs extra equipment | More portable and compact |

| Maintenance | Requires coolant monitoring and care | Lower maintenance |

| Typical Applications | Industrial, high-power, precision machining | Engraving, small-scale cutting |

Tip: Water cooling is essential for tubes above 100W or for long, demanding jobs. Air cooling works for smaller, portable systems.

You should follow these best practices for cooling:

- Use distilled water with a small amount of antifreeze to prevent corrosion and freezing.

- Maintain water flow at about 10 liters per minute and keep water temperature near 10°C for optimal performance.

- Avoid pure antifreeze or tosol, as these can damage pumps and reduce cooling efficiency.

- Monitor your cooling system regularly. A failed pump or low water flow can cause rapid tube damage.

- Stable cooling prevents thermal expansion, keeps your beam focused, and ensures consistent cutting quality.

Regular maintenance and proper coolant selection help you avoid costly downtime and extend the life of your laser tube.

Comparison of Types

Performance

When you compare laser tube types, performance stands out as a key factor. You want a tube that delivers fast cutting speeds and high engraving quality. DC glass tubes use direct current for excitation. This method limits their pulse frequency, so you get slower cutting speeds and slightly less detailed engraving. RF metal and ceramic tubes use radio frequency excitation. This technology allows for rapid pulsing, which means you achieve faster cutting and submicron engraving precision.

You can see the main differences in the table below:

| Characteristic | DC Glass CO2 Laser Tubes | RF Metal and Ceramic CO2 Laser Tubes |

|---|---|---|

| Excitation Method | Direct Current (DC) | Radio Frequency (RF) |

| Cutting Speed | Slower due to limited pulse frequency | Faster due to higher pulse rates |

| Engraving Quality | Slightly lower engraving detail | Finer engraving detail, submicron precision |

| Cooling Method | Water-cooled (due to poor thermal conductivity) | Air-cooled (fans integrated) |

| Power Stability | Less stable, potential power fluctuations | More stable and consistent power output |

| Material Compatibility | Best for non-metallic materials (wood, acrylic) | Suitable for metals, glass, ceramics, and more |

RF tubes also give you more precise control over power and speed. This feature helps you achieve detailed results on a wider range of materials. If you need high accuracy and speed, RF metal or ceramic tubes will serve you best.

Tip: For detailed engraving or working with metals and glass, choose an RF metal or ceramic tube for superior results.

Durability

Durability affects how long your investment lasts and how often you need to replace parts. DC glass tubes have a moderate lifespan, usually between 5,000 and 8,000 work hours, or about two years with regular use. Their glass construction makes them more fragile and prone to breakage.

RF metal tubes last longer, averaging 10,000 to 20,000 hours, or about six years. The metal housing resists physical damage, but metal electrodes can corrode over time. Ceramic tubes also reach 10,000 to 20,000 hours of use. Their ceramic electrodes do not corrode, so you get stable performance and fewer issues with gas contamination.

Here is a quick comparison:

| Laser Tube Type | Average Lifespan (Work Hours) | Average Lifespan (Years) | Material Characteristics and Notes |

|---|---|---|---|

| DC Glass | 5,000 – 8,000 | ~2 years | Glass construction; moderate lifespan; prone to breakage |

| RF Metal Core | 10,000 – 20,000 | ~6 years | Metal electrodes; susceptible to corrosion over time |

| RF Ceramic Core | 10,000 – 20,000 | ~6 years | Ceramic electrodes; no corrosion; longer lifespan and more stable performance |

You benefit from fewer replacements and less downtime when you choose RF metal or ceramic tubes. Ceramic tubes especially offer stable operation and resist contamination, making them a top choice for demanding environments.

Cost

Cost plays a major role in your decision. DC glass tubes have the lowest upfront price. You spend less at first, but you may need to replace them more often due to their shorter lifespan and fragility. RF metal tubes cost more initially, but their longer life and better performance can save you money over time. Ceramic tubes have the highest purchase price. However, their durability and low maintenance needs can make them the most cost-effective option for heavy or industrial use.

- DC Glass Tubes: Lowest initial cost, higher replacement frequency.

- RF Metal Tubes: Higher upfront cost, lower replacement rate, better long-term value.

- Ceramic Tubes: Highest initial investment, longest lifespan, minimal maintenance.

Note: Consider both the purchase price and the expected lifespan when you calculate the true cost of ownership.

Maintenance

You must pay close attention to maintenance when you operate a laser system. The type of tube you choose affects how much time and money you spend on upkeep. Each tube type—DC glass, RF metal, and ceramic—has its own maintenance needs. Understanding these requirements helps you plan for costs and avoid unexpected downtime.

Routine maintenance tasks include cleaning mirrors and lenses, checking beam alignment, and inspecting gas lines. You should also replace consumables like focusing lenses and mirrors regularly. The frequency of these tasks depends on how often you use your machine and the environment in which you work. Dusty or humid conditions increase the need for cleaning and inspection.

Here is a comparison of maintenance aspects for CO2 and fiber laser tubes:

| Maintenance Aspect | CO2 Laser Tubes | Fiber Laser Tubes |

|---|---|---|

| Routine Maintenance | Frequent cleaning of mirrors, lenses, beam alignment, and gas line checks | Less frequent cleaning, an enclosed beam path reduces maintenance |

| Consumables Replacement | Laser tubes, mirrors ($50-$200 each), focusing lenses are replaced regularly, often annually | Minimal consumables, no mirrors to replace |

| Scheduled Downtime | More frequent and longer due to complexity and consumables | Less frequent and shorter due to a simpler design |

| Labor and Training | Requires skilled operators with optics and maintenance training, and higher labor costs | Easier operation, less intensive training needed |

| Lifespan and Depreciation | Shorter lifespan (6-10 years), higher depreciation and obsolescence risk | Longer lifespan (8-12 years), slower depreciation |

| Impact on Total Cost of Ownership (TCO) | Higher operational expenses due to consumables, labor, downtime, and shorter lifespan | Lower operational expenses, less downtime, and longer lifespan |

You will notice that CO2 laser tubes require more frequent attention than fiber lasers. You need to clean optical components and check alignment often. You also must replace mirrors and lenses, which adds to your yearly expenses. Skilled labor is necessary for these tasks, so you may face higher labor costs and longer downtime if you lack trained staff.

Tip: Following the manufacturer’s maintenance schedule helps you avoid sudden failures and extends the life of your equipment.

The lifespan of consumables varies. If you run your machine at high power or in harsh environments, you will need to replace parts more often. Regular checks and timely replacements keep your system running smoothly and prevent costly repairs.

You should also consider the impact of maintenance on your total cost of ownership. Frequent downtime, consumable costs, and labor add up over time. Planning for these expenses helps you manage your budget and avoid surprises.

Key maintenance tips for CO2 laser tubes:

- Clean mirrors and lenses weekly or after heavy use.

- Check and adjust beam alignment monthly.

- Replace focusing lenses and mirrors as soon as you notice wear or reduced performance.

- Keep a log of maintenance activities to track part replacements and service intervals.

- Train your staff on proper cleaning and alignment procedures.

By staying proactive with maintenance, you ensure reliable performance and maximize the value of your investment.

Choosing a CO2 Laser Tube

Selection Factors

Selecting the right CO2 laser tube for your machine requires careful consideration of several factors. You want to ensure that your choice matches your application, fits your existing hardware, and aligns with your budget.

Application

Start by identifying the materials you plan to cut or engrave and their typical thickness. The power rating of your tube should match the demands of your work. For example:

- Thicker materials need higher wattage to achieve clean cuts and efficient speeds.

- Thinner materials benefit from lower power and a smaller focus size for detailed engraving.

- Different materials, such as wood, acrylic, or metals, absorb laser energy differently. Adjust your power and focus settings to match each type.

- The quality of the beam, measured by the M² factor, affects the sharpness and precision of your cuts.

- Consider the use of assist gases like oxygen or nitrogen, which can improve edge quality and cutting speed for certain materials.

You should also think about the size and type of the tube. The length and diameter must fit your machine’s frame and match the material thickness you plan to process.

Compatibility

Compatibility with your existing laser machine hardware is essential. Before purchasing a new tube, check the following:

- Ensure the tube matches your machine’s power supply voltage and connector types.

- Confirm that your controller and drivers support the tube type you select. For example, some controllers handle both glass and RF tubes, but not at the same time.

- Mounting style and tube dimensions must align with your machine’s design.

- Older machines may require significant upgrades or even a full rebuild to support modern tubes and controllers.

- Avoid costly modifications by verifying compatibility with your hardware before making a purchase.

Tip: Always consult your machine’s manual or manufacturer to confirm compatibility before ordering a replacement tube.

Budget

Your budget influences your choice between tube types and brands. Consider both the initial cost and long-term expenses:

- DC glass tubes offer a lower upfront price but require more frequent replacement.

- RF metal and ceramic tubes cost more initially but provide longer lifespans and reduced maintenance.

- Factor in the cost of cooling systems, installation, and potential hardware upgrades.

- Weigh the total cost of ownership, not just the purchase price.

Replacement Tips

When you need to replace your CO2 laser tube, follow these steps to ensure safety and optimal performance:

- Power off and unplug your laser machine. Wait for all components to cool down.

- Drain the water cooling system by disconnecting the inlet and outlet hoses.

- Carefully disconnect all electrical wiring and loosen any clamps holding the old tube.

- Remove the old tube gently, as it is fragile.

- Position the new tube in place, aligning it with the laser optics. Secure it without over-tightening.

- Reconnect the electrical wiring and water cooling hoses, checking for secure connections and no leaks.

- Adjust the laser beam alignment using the mirrors and lenses.

- Test the new tube at low power first. Gradually increase power while monitoring cooling and performance.

Note: Matching the tube’s length and diameter to your machine is crucial. Some brands offer interchangeable tubes, but always verify dimensions and connector types before installation.

By considering your application, ensuring compatibility, and following proper replacement procedures, you maximize the performance and lifespan of your CO2 laser tube.

Practical Tips

Installation

Proper installation ensures your laser system operates safely and efficiently. Follow these steps for a smooth setup:

- Connect the water inlet hose to the anode side of the laser tube. Attach the outlet hose to the cathode side.

- Position the water outlet fitting so it points upward, with a tilt between 10 and 30 degrees. If the fitting points down or sideways, adjust the tube by loosening the top fastener and rotating it until correct.

- Secure all silicone tube connections with plastic ties. This prevents leaks and keeps your cooling system reliable.

- Handle the laser tube gently. The glass is fragile and can break easily.

- For machines with two tubes, repeat the process for each one.

- If you encounter difficulties, consult video tutorials or reach out to technical support.

Tip: Always double-check your connections before powering on the machine. Water leaks can cause serious damage.

Safety

Laser machines require strict safety measures. You protect yourself and your equipment by following these guidelines:

- Keep all safety interlocks and covers in place. The machine will disable the laser if the doors are open.

- Wear personal protective equipment (PPE) if you must open non-interlocked doors during operation.

- Never stare at the laser beam or the red pointer. Use protective eyewear rated OD 5+ when necessary.

- Avoid placing reflective objects in the cutting chamber. Reflected beams can escape and cause injury.

- Do not modify or disable any safety features. Only trained personnel should perform repairs or adjustments.

- Always activate the water-cooling system before turning on the laser.

- Keep flammable, explosive, or corrosive materials away from the machine.

- Use the machine only on approved materials and with proper settings.

- Operate the machine in a clean, flat workspace. Never leave it unattended during operation.

| Safety Area | Key Actions |

|---|---|

| Laser Safety | Keep covers closed, use a smoke purifier, and follow ANSI Z136.1-2000 standards. |

| Fire Safety | Remove flammable materials, clean residues, and keep the extinguisher nearby. |

| Electrical Safety | Inspect power cords, avoid exposed wiring, and use the correct power supply. |

| General Safety | Inspect for damage, maintain cleanliness, and avoid unauthorized modifications. |

Note: The U.S. FDA regulates laser safety under Title 21 CFR Subchapter J. Always check for proper warning labels and certifications.

Maintenance

Routine maintenance extends the life of your laser tube and keeps your machine running smoothly. Use this checklist to stay on track:

- Check the cooling system regularly. Use distilled or deionized water to prevent mineral buildup. Monitor water levels and clean the chiller to avoid overheating.

- Clean mirrors and lenses often. Dust and residue reduce efficiency and can cause overheating.

- Inspect the tube and cooling system for leaks. Even small leaks can impact performance.

- Test the water pump to ensure proper flow. Replace it if you notice weak circulation.

- Wipe the tube to remove condensation or debris.

- Adjust power and speed settings for each material. Use the lowest effective power and avoid running at full power for long periods.

- Allow cooling breaks during extended jobs.

- Store your machine in a cool, dry place. Avoid high humidity and direct sunlight.

Callout: Overheating, poor water flow, and dirty optics are common causes of tube failure. Recognize early signs like reduced power or color changes in the laser pulse. Replace the tube promptly to prevent downtime.

Maintain a stable environment. Operate your machine between 68–90°F (20–32°C) and 35–80% humidity. Climate control helps prevent water vapor inside the tube and ensures consistent performance.

Choosing the right laser tube depends on your needs and priorities. Review the key differences:

| Feature | DC Glass Tubes | RF Metal Tubes | RF Ceramic Tubes |

|---|---|---|---|

| Cost | Low | Medium | High |

| Durability | Moderate | High | Highest |

| Performance | Good | Excellent | Superior |

| Maintenance | Frequent | Less frequent | Minimal |

| Cooling | Water | Air/Water | Air/Water |

| Lifespan | 5,000–8,000 h | 10,000–20,000 h | 10,000–20,000 h |

- Match tube power to your material and thickness for best results. Proper power prevents damage, improves quality, and keeps your workspace safe.

- Always check compatibility, cooling needs, and maintenance requirements before you buy.

For more guidance, explore maintenance guides, schedule regular inspections, and consult experts for personalized advice.

FAQ

What materials can you cut or engrave with a CO2 laser tube?

You can process wood, acrylic, leather, paper, glass, rubber, and some plastics. CO2 laser tubes do not cut most metals efficiently. For metals, you need a fiber laser or a specialized CO2 system with assist gas.

How often should you replace a CO2 laser tube?

You should replace a DC glass tube every 3,000–8,000 hours. RF metal and ceramic tubes last 10,000–20,000 hours. Monitor power output. If you notice a drop in performance, plan for replacement.

Can you upgrade your machine from a glass tube to an RF metal or ceramic tube?

You can upgrade, but you must check compatibility. RF tubes require different power supplies and controllers. You may need to modify mounts and cooling systems. Consult your machine’s manufacturer before upgrading.

What cooling system should you use for your CO2 laser tube?

For tubes above 100W, use water cooling. For lower-power tubes, air cooling may work. Always keep coolant clean and at the right temperature. Proper cooling prevents overheating and extends tube life.

How do you know if your CO2 laser tube is failing?

Watch for these signs:

- Reduced cutting or engraving power

- Unstable or flickering beam

- Color change in the laser spot

- Unusual noises or overheating

Tip: Replace the tube promptly to avoid machine damage.

Is it safe to install a CO2 laser tube yourself?

You can install a tube if you follow safety guidelines. Always disconnect power, wear protective gear, and avoid touching the glass. If unsure, ask a technician for help.

Do all CO2 laser tubes fit any laser machine?

No. Tubes vary in length, diameter, and connector type. Always check your machine’s specifications. Use only compatible tubes to ensure safe and effective operation.

How can you extend the lifespan of your CO2 laser tube?

Keep the cooling system clean. Avoid running at full power for long periods. Clean optics regularly. Operate in a dust-free environment. Schedule routine maintenance.