Tube laser CO2 systems are essential for precision cutting and engraving in various industries. Whether you are a hobbyist or a professional, understanding the features and benefits of tube laser CO2 products can help you make an informed decision when purchasing. In this guide, we will explore everything you need to know about tube laser CO2 laser tubes, including power options, stock availability, pricing, and how to place your order efficiently.

Understanding Tube Laser CO2 Technology and CO2 Laser Tubes

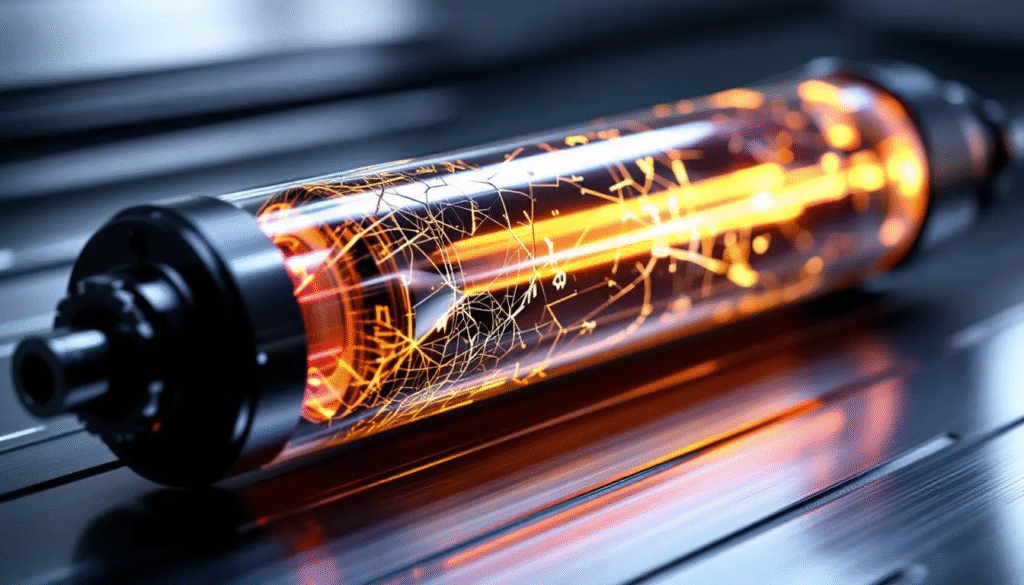

Tube laser CO2 machines utilize laser tubes filled with carbon dioxide gas to generate a focused beam of infrared light. This beam is capable of cutting, engraving, and marking various materials such as wood, acrylic, leather, and certain metals. The laser tubes are the heart of the system, and their quality directly impacts the performance and lifespan of the machine.

The power of a CO2 laser tube is measured in watts, determining the cutting speed and thickness of materials that can be processed. For instance, a higher power tube can cut thicker materials more quickly, making it ideal for industrial applications. Conversely, lower power tubes are suitable for detailed engraving and thinner materials.

Types of Laser Tubes: Exploring Your Options

When selecting a CO2 laser tube for your system, it’s important to understand the different types available and how they impact your machine’s performance. The two most common types of laser tubes used in CO2 laser systems are glass (DC) tubes and metal (RF) tubes, each offering unique advantages for various applications. Additionally, the typical length for CO2 laser tubes can be 700mm, 720mm, 800mm, 1240mm, and 1650mm, so ensure the tube length matches your system’s requirements.

**Glass (DC) Laser Tubes:**Glass laser tubes are the most widely used option for hobbyists and small businesses. These tubes are typically more affordable, making them a popular choice for those looking to keep the cart price low while still achieving reliable results. Glass tubes are available in a range of power ratings, from 40W up to 150W or more, and are well-suited for cutting and engraving non-metallic materials like wood, acrylic, and leather. Laser tubes are often sealed with a glass construction, which contributes to their affordability and performance. While they offer excellent value, glass tubes generally have a shorter lifespan compared to metal tubes and require careful handling due to their fragile construction.

Metal (RF) Laser Tubes: Metal, or radio frequency (RF), laser tubes are designed for high-performance and industrial applications. These tubes are more durable and offer a longer operational life, often exceeding 10,000 hours of use. Metal tubes provide superior beam quality and faster response times, making them ideal for detailed engraving and high-speed production environments. However, they come at a higher price point, which is reflected in the cart and checkout totals. If you require consistent, high-quality output and minimal downtime, investing in a metal CO2 laser tube is recommended.

Hybrid and Specialized Tubes: Some manufacturers offer hybrid or specialized laser tubes that combine features of both glass and metal designs, or are tailored for specific materials and tasks. These products can offer a balance between price, performance, and longevity, and may be recommended for users with unique requirements.

When browsing products and adding items to your cart, consider your intended use, budget, and the compatibility of the tube with your existing laser system. Reviewing the available stock and comparing the features of each type will help you make an informed order that meets your needs.

Choosing the Right Power for Your Tube Laser CO2 and CO2 Laser Tubes

Selecting the appropriate power for your tube laser CO2 depends on your specific needs. Common power ratings for laser tubes range from 40W to 150W or more. If you primarily work with thin materials like paper or fabric, a 40W to 60W tube is recommended. For cutting thicker materials such as wood or acrylic, consider a 100W or higher tube for optimal efficiencyHigh-wattagege CO2 laser tubes, like 130W and 150W, typically have higher prices and are designed for more powerful cutting and engraving applications.

It is also important to consider the compatibility of the laser tube with your existing machine. Some systems require specific tube sizes and power ratings, so always verify the manufacturer’s recommendations before making a purchase. Most CO2 laser tubes have a diameter of either 50mm or 80mm, which should be checked to ensure proper fit.

Maintenance and Safety Precautions for CO2 Laser Tubes

Proper maintenance and safety practices are essential for getting the most out of your CO2 laser tubes and ensuring a safe working environment. Regular care not only extends the lifespan of your laser tube but also maintains the quality and consistency of your cutting and engraving results.

**Routine Maintenance Tips:**To keep your laser tube operating at peak performance, it’s important to follow a regular maintenance schedule. This includes cleaning the tube and optical components to prevent dust and debris buildup, which can affect beam quality. Ensure that the cooling system—whether water or air-cooled—is functioning correctly, as overheating can significantly reduce the tube’s lifespan. Replacement of a CO2 laser tube is typically recommended every 12 months for optimal engraving results. Periodically check for any signs of wear or damage, and replace worn parts promptly to avoid unexpected downtime.

Safety Precautions: Handling and operating CO2 laser tubes require attention to safety. Always power off and unplug your machine before performing any maintenance or replacing the tube. Wear appropriate protective gear, such as safety glasses rated for infrared light, to shield your eyes from accidental exposure. Be mindful of the high voltages involved in laser tube operation, and avoid touching electrical components unless you are qualified to do so.

Storage and Handling: When storing spare laser tubes, keep them in a dry, dust-free environment and handle them with care to prevent breakage. Always follow the manufacturer’s guidelines for installation and operation to ensure safe and effective use of your products.

By incorporating these maintenance and safety practices into your routine, you can protect your investment and enjoy reliable performance from your CO2 laser tubes. For more detailed recommendations, consult your product manual or reach out to your supplier for support on best practices tailored to your specific laser tube model.

Stock Availability and Cart Price Considerations for Tube Laser CO2 Products

When shopping for tube laser CO2 products, stock availability is a crucial factor. Reputable suppliers maintain a healthy inventory of laser tubes to ensure quick shipping and minimal downtime for customers. Before adding items to your cart, check the stock status to avoid delays.

Price is another significant consideration. The price of CO2 laser tubes varies based on power, brand, and quality. While it might be tempting to opt for the lowest price, investing in recommended products with proven durability can save money in the long run by reducing replacement frequency.

Many online stores display the cart price dynamically as you add items, allowing you to keep track of your budget. Make sure to review your cart carefully before proceeding to checkout to confirm that all desired products are included and the total price meets your expectations.

How to Order Tube Laser CO2 Products Efficiently: Tips for Ordering CO2 Laser Tubes

Ordering tube laser CO2 products online is straightforward if you follow a few simple steps. First, browse the available laser tubes and filter by power, price, or brand to narrow down your options. Once you find the recommended products that suit your needs, add them to your cart.

Before checking out, double-check the stock status and ensure that the tube size and power match your machine’s specifications. Many websites offer detailed product descriptions and customer reviews, which can help you make an informed decision. Replacement tubes should match the length and diameter of the existing tube for compatibility, so verify these dimensions carefully before finalizing your purchase.

Proceed to checkout by providing your shipping and payment information. Some suppliers offer discounts or bundle deals when you order multiple products, so keep an eye out for special offers that can enhance your purchase value. The installation process of CO2 laser tubes can vary, with some models claiming super-easy installation features, which can save time and effort during setup.

For more detailed technical information on CO2 laser tubes, you can visit LightObject’s Laser Tube Guide, a reputable resource for laser tube specifications and compatibility.

Conclusion: Why Choose Recommended Tube Laser CO2 Laser Tubes

Investing in high-quality tube laser CO2 tubes is essential for achieving precise and efficient cutting and engraving results. By understanding the technology, selecting the right power, considering stock and price, and following an efficient ordering process, you can ensure a smooth purchasing experience. Remember to prioritize recommended products to maximize the lifespan and performance of your laser system. Whether you are upgrading your existing machine or purchasing a new one, the right CO2 laser tubes will make all the difference in your projects.

For more tips on laser tube maintenance and selection, check out our internal guide on Laser Tube Maintenance Best Practices.