When it comes to precision cutting and engraving, the 150W CO2 laser stands out as a powerful and versatile tool. Whether you are a professional manufacturer or a hobbyist interested in various projects, understanding the features, performance, and usage of a 150-w CO2 laser can help you make an informed purchase. This article covers everything from laser beam quality to auxiliary equipment, ensuring you get the best out of your laser engraver or cutter.

Introduction to High-Power Lasers

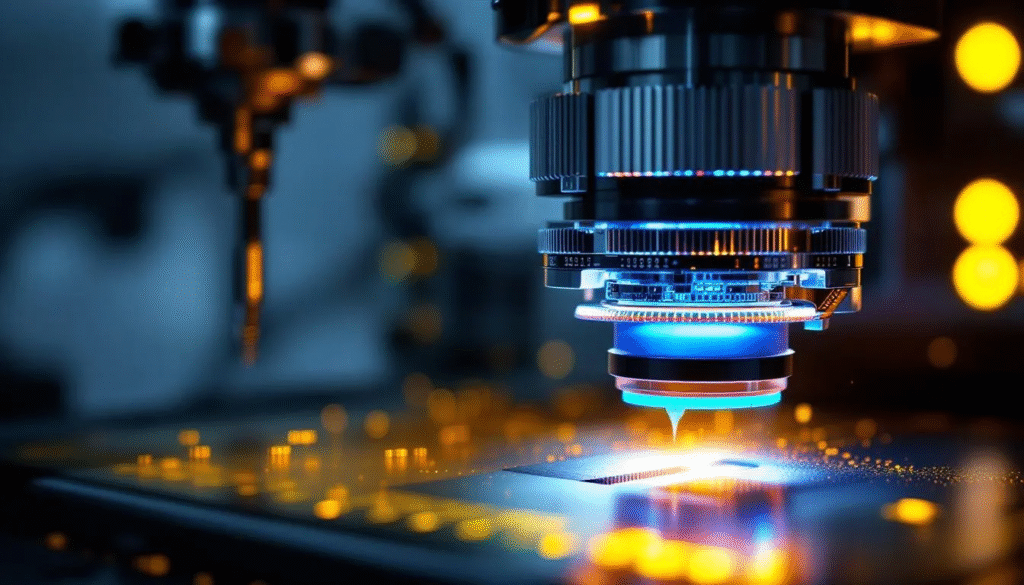

High-power lasers, such as the 150W CO2 laser, are at the forefront of modern cutting and engraving technology. These machines harness the energy of a robust CO2 laser tube to deliver exceptional laser beam quality, enabling precise cutting and detailed engraving on a wide range of materials, including wood, acrylic, and leather. The minimum power required for each project depends on the thickness and type of material, but the 150-w CO2 provides ample power for both delicate engraving and deep, clean cuts.

The design of the machine body and the integration of auxiliary equipment—like cooling and exhaust systems—are crucial for maintaining optimal performance and extending the service life of the laser tube. Proper usage and regular maintenance can significantly increase the lifetime of your CO2 laser, ensuring consistent results and reducing the need for frequent replacements. Whether you’re working on intricate wood inlays or large acrylic signage, the high power and reliability of a150-ww CO2 laser make it a valuable asset for any workshop or production line.

Understanding the 150w CO2 Laser and Its Performance

Th150-w0w CO2 laser is a high-power laser system designed for cutting and engraving a wide range of materials. Its power output of 150 watts allows for precise cutting through materials such as wood, acrylic, leather, plywood, plastic, and even glass. The laser beam quality plays a crucial role in its performance, influencing the sharpness and consistency of cuts and engravings. A high-qualiCO2co2 laser tube ensures that the laser beam remains stable and focused throughout its lifespan.

One of the key benefits of a 150w CO2 laser is its ability to handle both high-speed engraving and deep cutting. This versatility makes it suitable for various projects, from intricate designs on leather to larger cuts on plywood sheets. Many models also feature pass-through doors or pass-through sizes, allowing material to pass through different sections of the machine. This pass-through capability enables users to accommodate larger materials and ensures a seamless workflow for sizable projects.

Additionally, the machine body is typically designed to support the high power output, with robust hardware and a stable work area to maintain precision. The OMTech Maker AF4063-150 includes an autofocus feature, which further enhances precision cutting and engraving by automatically adjusting the focus for optimal results.

Key Components: Laser Tube, Mirrors, Lenses, and Machine Body

At the heart of the 150-ww CO2 laser system is thCO2o2 laser tube, which generates the laser beam. The quality and lifespan of this tube are critical; many manufacturers provide information on the tube’s lifetime, often measured in hours of running time. The estimated service life of the OMTech 150W CO2 laser tube is up to 12,000 hours, ensuring long-term usage without frequent replacements. The lifespan of a CO2 laser tube can vary, but a well-maintained tube can last thousands of hours, ensuring long-term usage without frequent replacements.

Mirrors and lenses are equally important auxiliary equipment that guide and focus the laser beam onto the material. High-quality mirrors and lenses reduce energy loss and improve cutting accuracy. Some machines offer optional autofocus features that automatically adjust the lens position to maintain optimal focus, further enhancing ease of use and precision.

The machine body is engineered to support these components securely. A well-constructed frame reduces vibrations and ensures that the laser beam passes consistently over the work area. The package dimensions and weight of the machine can vary, so it’s important to consider your workspace and shipping options when purchasing.

Auxiliary Systems: Cooling, Exhaust, and Air Assist

Auxiliary systems are essential for getting the best performance from your laser engraver or cutter. The cooling system, often water- or chiller-based, keeps the laser tube at a stable temperature, preventing overheating and helping to maximize the tube’s lifespan. An efficient exhaust system is equally important, as it removes smoke, fumes, and debris generated during engraving and cutting, protecting both the machine and the operator while maintaining a clean work area.

The air assist system is another key component, directing a steady stream of air at the cutting or engraving point. This not only clears away debris for cleaner cuts but also helps prevent flare-ups and improves the overall quality of the finished piece. Together, these auxiliary systems ensure your laser engraver operates smoothly, delivers high-quality results, and requires less frequent maintenance, making them indispensable for anyone seeking professional-grade performance.

Software, Manual Adjustments, and Ease of Use

The software used to control a 150-w CO2 laser engraver or cutter is another vital aspect. Good software should be compatible with various file formats and provide users with the ability to adjust settings such as speed, power, and engraving depth. Some machines come with user-friendly interfaces that reduce guesswork, allowing even beginners to achieve professional results. Many models also feature a dedicated button to effortlessly raise or lower the motorized workbed, making adjustment easy and giving users precise control. The OMTech Maker AF4063-150 supports multiple compatible operating systems, including Windows 2000, XP, Vista, 7, 8, and 10, ensuring broad accessibility for users.

Manual adjustments are often necessary to fine-tune the laser cutter’s performance. These may include setting the focus manually, adjusting the speed for different materials, or calibrating the machine for consistent output. While some models include automated features, having manual control options ensures flexibility and precision for a variety of projects. The OMTech Maker AF4063-150 features dual motorized workbeds, making height adjustments easier and more efficient for users handling diverse materials.

Safety Features and Precautions

Working with a high-power 150-ww CO2 laser demands strict attention to safety. The ISO class rating of your machine indicates the level of safety measures required, and it’s essential to follow all recommended guidelines to protect both users and equipment. Manual adjustments, such as aligning the laser beam and calibrating the focus, should be performed carefully to ensure precise cutting and engraving while avoiding accidental damage to the laser tube or other components.

When setting up or moving your machine, consider the package dimensions and weight to ensure safe handling and installation. Always use appropriate personal protective equipment, such as safety glasses rated for CO2 lasers, and make sure your workspace is well-ventilated. By adhering to these precautions and maintaining your machine according to the manufacturer’s recommendations, you can ensure a safe environment and prolong the life of your high-power CO2 laser system.

Materials Compatible with 150-w0w CO2 Laser

One of the reasons the 150-w CO2 laser is popular among customers is its ability to work with a wide variety of materials. Wood, acrylic, leather, plywood, plastic, and glass are commonly processed materials. In addition, the machine can also engrave cylindrical objects such as tubes, cups, bottles, and pipes, supporting 360° engraving. The OMTech Maker AF4063-150 allows for 360° engravings on cylindrical objects using a rotary axis, making it an excellent choice for projects requiring detailed designs on curved surfaces. The laser’s high power allows it to cut through thicker materials like plywood and acrylic with ease, while also engraving delicate designs on softer materials such as leather and wood.

It’s important to note that different materials require different laser settings. Lower settings may be used for engraving on plastic or wood to avoid burning, while higher power and slower speeds are ideal for cutting thicker materials. The flexibility in settings makes the 150-w CO2 laser suitable for diverse applications, from hobbyist projects to industrial manufacturing.

Applications and Industries

The versatility of the 150-ww CO2 laser tube makes it a popular choice across a variety of industries and applications. From woodworking shops crafting custom furniture and décor, to acrylic fabricators producing signage and displays, to leatherworkers engraving intricate patterns, the precise cutting and engraving capabilities of these machines open up endless creative possibilities. The high power of the laser tube allows for both fine engraving and deep cutting, making it suitable for a wide range of materials and project types.

Modern laser engravers are compatible with advanced software like RDWorks and LightBurn, which offer intuitive interfaces for designing and editing projects. This flexibility enables users to bring their ideas to life, whether they’re producing one-of-a-kind pieces or running large-scale production. With the ability to cut and engrave wood, acrylic, leather, and more, the t150-w50w CO2 laser is an indispensable tool for businesses and hobbyists alike, supporting a diverse variety of projects and industries.

Purchasing Considerations: Prices, Package, and Optional Accessories

When looking to purchase a 150-watt CO2 laser machine, customers should consider several factors beyond just the base price. The package often includes essential components such as the laser tube, mirrors, lenses, and sometimes auxiliary equipment like air assist systems or exhaust fans. Optional accessories can enhance the machine’s capabilities, including autofocus lenses, rotary attachments for cylindrical objects, and upgraded software packages.

Prices for a 150-w CO2 laser system can vary widely depending on the brand, included features, and warranty terms. It’s advisable to review the seller’s reputation, check for ISO class certifications that ensure quality standards, and understand the service life and maintenance requirements of the laser tube and other hardware. Choosing a best-selling or popular seller can also provide added trust and confidence in your purchase.

Shipping and package dimensions also matter, especially for customers planning to ship the machine internationally or to locations with limited space. Many sellers provide a comprehensive list of product specifications and PDF manuals to help buyers understand what is covered in the purchase and how to set up the machine properly.

Maximizing the Lifespan and Performance of Your 150w CO2 Laser

To ensure consistent performance and maximize the lifespan of your 150-w CO2 laser, regular maintenance and proper usage are essential. Cleaning the lenses and mirrors regularly prevents energy loss and maintains laser beam quality. Monitoring theCO22 laser tube’s running hours and replacing it before it reaches the end of its lifetime will avoid unexpected downtime.

Using the machine within recommended power and speed settings and avoiding prolonged operation at max power can extend the life of the laser tube. Additionally, ensuring that the machine body remains stable and that all hardware components are securely fastened contributes to reliable operation.

Troubleshooting and Support

Maintaining peak performance from your laser engraver or cutter requires effective troubleshooting and reliable support. Common issues, such as misaligned mirrors or dirty lenses, can often be resolved by consulting the comprehensive PDF manual provided with your machine or by reaching out to the seller’s support team. Regular maintenance, including cleaning optical components and operating the laser at lower settings when possible, helps extend the service life of the CO2 laser tube and ensures consistent, high-quality results.

If you encounter persistent problems or need to make a return, most reputable sellers offer clear policies for order cancellation and product returns within a specified timeframe. By providing detailed troubleshooting guides and responsive customer support, sellers help customers maximize the life and performance of their laser engraver, ensuring every project is completed to professional standards.

The 15150-wO2 laser is a powerful and versatile tool ideal for precise cutting and engraving across a variety of materials. From the high-quality cCO2laser tube and auxiliary equipment to the software and manual adjustments, each component plays a role in delivering consistent, professional results. Whether you are interested in woodworking, acrylic projects, leather engraving, or industrial applications, understanding the features, performance, and maintenance of a 150-w CO2 laser will help you make the most of this advanced laser cutter and engraver. When considering a purchase, pay attention to package details, prices, and optional accessories to ensure you get the best value and performance for your money.