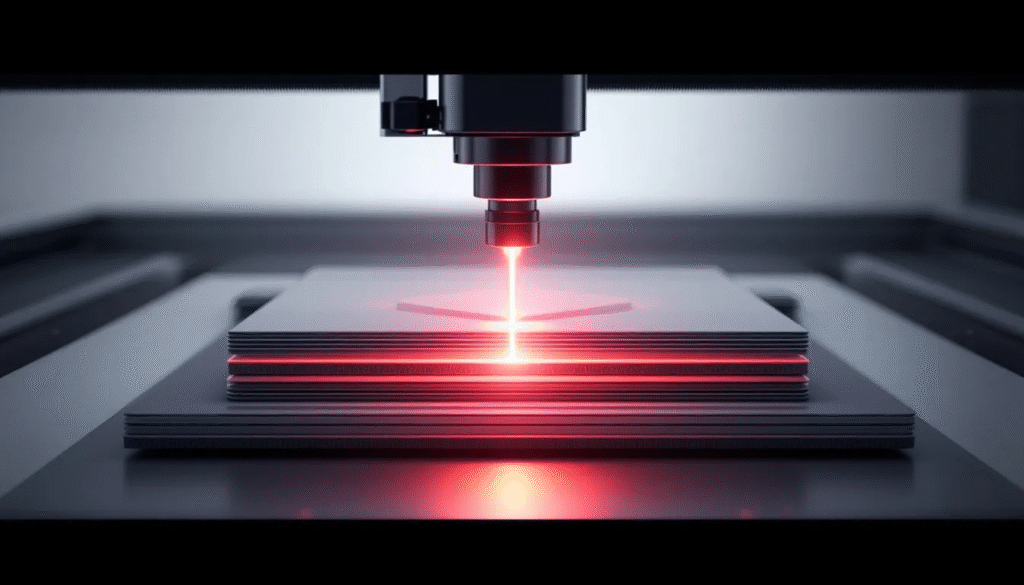

When it comes to laser engraving and cutting, the CO2 glass laser tube plays a pivotal role in determining the performance and quality of the process. Whether you are a small business owner looking to invest in a reliable laser engraver or a hobbyist seeking precision, understanding the nuances of glass laser tubes is essential.

There are a variety of CO2 glass laser tube products available on the market, and this guide will help you find the best option to suit your specific needs.

This article explores the features, advantages, and considerations of CO2 glass laser tubes, enabling you to make an informed decision.

What is a CO2 Glass Laser Tube?

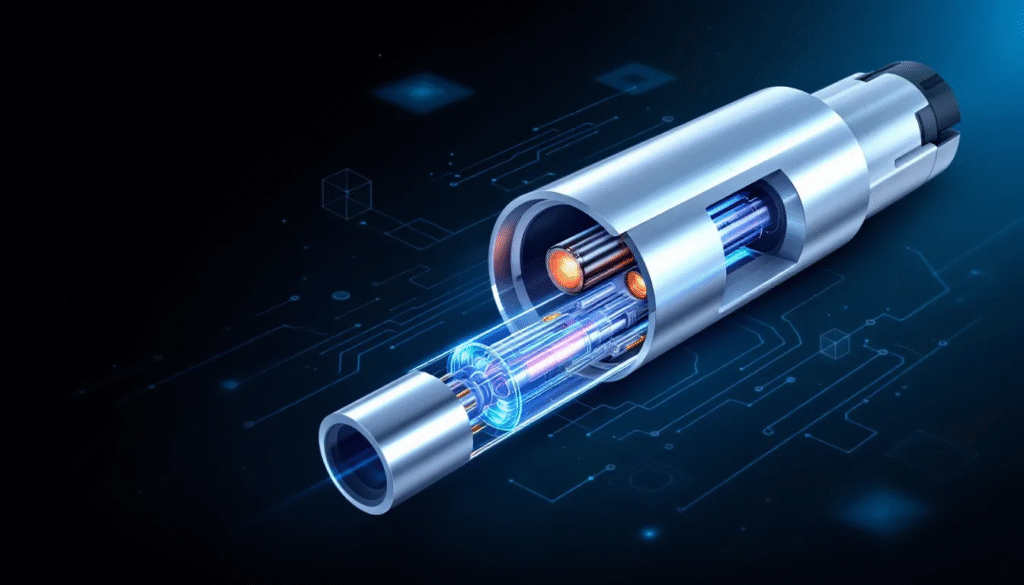

A CO2 glass laser tube is a type of laser tube that uses carbon dioxide gas enclosed within a glass tube to generate laser light. These glass tubes are filled with a mixture of gases, primarily carbon dioxide, nitrogen, and helium, which, when excited by a direct current, emit infrared laser beams. High-voltage current excites this mixture of gases to produce the laser beam. The emission of laser light occurs naturally as a result of the excited gas mixture. The tube itself is typically made of durable glass, designed to withstand the heat and pressure generated during operation.

Unlike metal or radio frequency (RF) tubes, which use different excitation methods, CO2 glass laser tubes operate on direct current (DC) excitation. This means that an electrical current passes directly through the gas mixture, exciting the gas and stimulating the emission of the laser beam. This form of excitation is generally simpler and more affordable, making glass laser tubes a popular choice for many applications.

Operating Principles of CO2 Glass Laser Tubes

CO2 glass laser tubes function by exciting a carefully balanced gas mixture—primarily carbon dioxide, nitrogen, and helium—inside a sealed glass tube. When direct current (DC) electricity is applied, it energizes the gas, causing it to emit a powerful laser beam. This process is at the heart of how these laser tubes deliver the high output power needed for precise engraving and cutting tasks.

The glass construction of these tubes is engineered to handle the intense heat and pressure generated during operation, making them a reliable choice for many laser applications. Unlike radio frequency (RF) tubes, which use radio frequency energy to excite the gas, glass laser tubes rely on direct current. This difference in excitation method means that while glass tubes are generally more affordable and straightforward to use, they may have a shorter lifetime, usually around 1,500 to 3,000 hours, and slightly lower durability compared to their RF counterparts. Nevertheless, the process allows for effective performance in a wide range of engraving and cutting projects, making glass laser tubes a popular option for both small businesses and hobbyists.

Advantages of Glass CO2 Laser Tubes

One of the primary advantages of glass laser tubes is their affordable price compared to other types, like RF tubes. This cost-effectiveness makes them well-suited for small businesses and individuals who need a reliable yet budget-friendly laser solution.

In addition to cost, glass CO2 laser tubes offer several performance benefits. They typically provide a high output power, which translates to faster cutting and engraving speeds. Regular maintenance and proper use can increase the performance and lifespan of the tube. This increased speed is particularly beneficial when working with materials such as acrylic, wood, leather, and even cardboard, ceramics, glass, paper, and stone, allowing users to complete projects more efficiently. The faster speeds of glass CO2 laser tubes also enable users to finish more projects within a single day, boosting productivity.

Moreover, the smaller spot size achievable with glass tubes enables the laser to capture finer details in engraving, enhancing the quality of the final product. A lower M² factor (closer to 1) indicates better beam quality, leading to finer details and sharper edges. However, glass CO2 laser tubes generate a beam that is less stable and has a larger spot size, which may reduce the accuracy and detail of engraving and cutting. This precision is essential for applications requiring delicate and intricate designs.

Power Rating and Efficiency

The power rating of a CO2 laser tube is a critical factor when choosing the right tube for your application. Generally, a higher power rating enables faster engraving and cutting speeds, allowing you to work with thicker or tougher materials. However, increased power also brings a higher risk of damage to the tube and other machine components if not managed properly.

Efficiency is another important consideration. Glass CO2 laser tubes typically have lower efficiency compared to metal tubes, which means they may consume more energy and require more frequent maintenance. This can lead to higher operational costs and a shorter lifespan for the tube. Glass CO2 laser tubes require water cooling at all times to prevent overheating due to their less efficient thermal conductivity, which adds complexity and can lead to overheating if the system fails. Despite this, glass tubes remain an affordable option, especially for those who need reliable performance without a significant upfront investment. When used correctly, glass laser tubes can still deliver excellent engraving and cutting results, making them a cost-effective choice for many applications.

Cooling Systems and Maintenance

A crucial aspect of operating a CO2 glass laser tube is managing the heat generated during use. Most glass laser tubes feature a water cooling system that continuously circulates water around the tube to efficiently remove heat. Water cooling systems, however, introduce more points of failure that need maintenance. This cooling system is vital for maintaining the tube’s durability and extending its lifetime. A well-maintained cooling system avoids safety issues and overheating.

Proper maintenance of the cooling system helps avoid damage caused by overheating, which can drastically reduce the life of the tube. Regularly checking the water flow and temperature ensures that the tube operates within safe limits, preserving its performance over time.

Additionally, glass laser tubes generally require less maintenance compared to metal or RF tubes. Their simpler construction and operation reduce the number of maintenance items and overall maintenance requirements, meaning fewer parts that can fail, making them easier to service and maintain. However, they may still need periodic gas refills, which adds to the maintenance routine. This additional maintenance requirement can make them less convenient compared to RF tubes, which are typically maintenance-free.

This reduction in maintenance items also reduces the number of potential safety concerns.

Safety Precautions and Handling

Proper safety precautions are essential when working with CO2 laser tubes to protect both the equipment and the operator. Always wear appropriate protective gear, such as gloves and safety glasses, when handling glass tubes. Ensure that your laser machine is correctly grounded and that the workspace is well-ventilated to avoid any risks associated with gas leaks or overheating.

The cooling system—most commonly water cooling—should be checked regularly to maintain optimal performance and prevent heat-related damage. Glass tubes are particularly sensitive to temperature changes, so keeping the cooling system in good working order is crucial for extending the life and maintaining the performance of your laser tube. Users should clean and check the tube’s mirrors every week and the lens every day. By following these safety protocols and handling procedures, you can reduce the risk of damage and ensure your CO2 laser tube delivers reliable results over its lifetime.

Applications and Suitability

Glass CO2 laser tubes are suited for a wide range of applications, from industrial manufacturing to creative projects. Their ability to handle various materials such as acrylic, wood, and leather makes them versatile tools for cutting and engraving.

For businesses that demand high precision and speed, these tubes provide an excellent balance between cost and performance. They are commonly found in laser engravers used by small to medium-sized enterprises, where affordability and reliability are key factors. The resulting engravings produced by glass CO2 laser tubes are detailed and precise, adding significant value to the finished product.

Furthermore, the durability and longer lifespan of glass laser tubes mean fewer replacements and lower overall operating costs, an important consideration for daily use.

Troubleshooting Common Issues

Even with proper care, CO2 glass laser tubes can sometimes experience issues such as reduced output power, poor beam quality, or premature failure. These issues frequently arise from inadequate maintenance, excessive heat, or physical harm to the tube or its parts. Running a CO2 laser tube at maximum power will vastly diminish its lifetime, so it is crucial to operate the tube within its recommended power range to avoid accelerated wear and tear. Overdriving a CO2 laser tube accelerates the disintegration of CO2 into Oxygen and Carbon Monoxide, further reducing its efficiency and lifespan.

To troubleshoot these issues, start by inspecting the cooling system to ensure it is functioning correctly and efficiently dissipating heat. Cleaning the tube and optics can also help restore performance, as dust and residue can interfere with the laser beam. Make sure your laser machine is properly aligned and configured, as misalignment can lead to sub.

Choosing the Right CO2 Glass Laser Tube

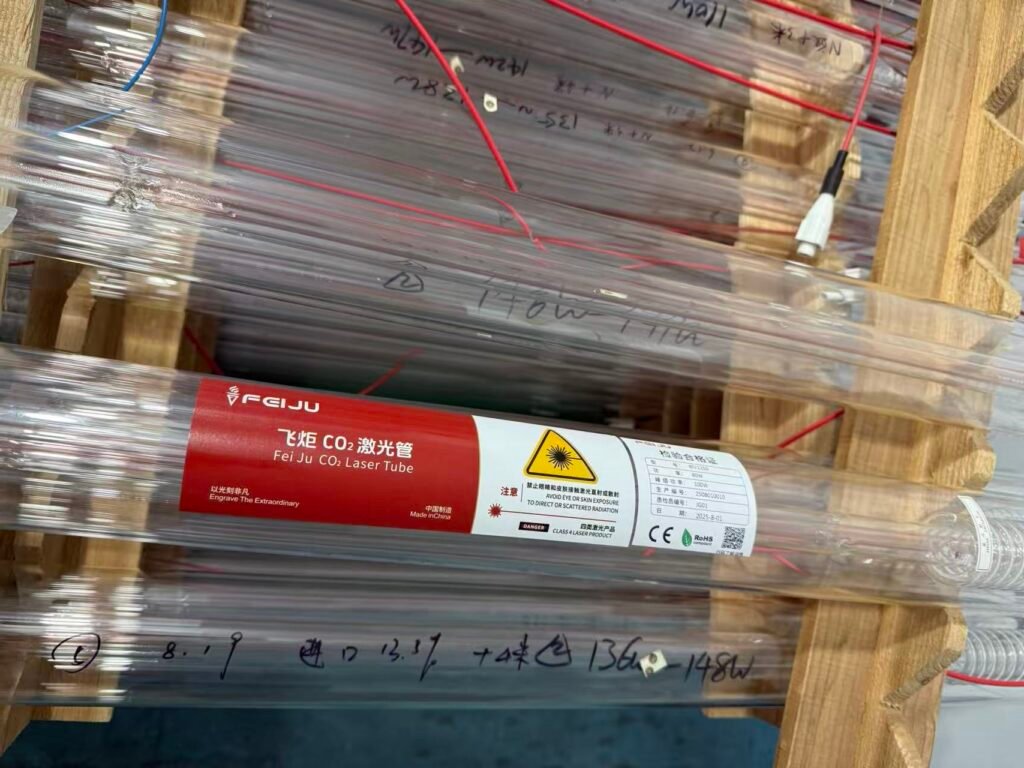

When choosing a glass CO2 laser, several factors need to be considered to ensure optimal performance for your specific engraving needs. The length of the tube affects the laser’s power and focus, so choosing the right size based on your machine’s specifications is important.

The output power rating should align with the materials and thicknesses you plan to work with. Higher power tubes enable faster processing and the ability to cut thicker material, but this may come at a higher price. Higher quality tubes can also switch quickly, which improves engraving speed and detail. Additionally, the number of pulsing times per second (pulse frequency) directly impacts the speed and quality of engraving.

It’s also essential to verify the compatibility of the tube with your existing machine, including the cooling system and power supply. Choosing a tube with a reliable cooling system and ensuring proper installation minimizes the risk of damage and extends the tube’s lifetime. Many suppliers market tubes at their ‘maximum power’ instead of their correct ‘rated power,’ which can be misleading. If your current tube reaches the end of its service life, you may need to purchase a new one, so consider warranty coverage and reputable suppliers. You can also add compatible accessories or options to enhance your laser system.

Conclusion

In summary, the CO2 glass laser tube is a fundamental component in laser engraving and cutting machines, offering an affordable and effective option for various applications. Its combination of affordable price, high output power, and durability makes it a popular choice among small businesses and hobbyists alike. Companies like RECI are known for superior beam quality, longer lifespans, and reliability in CO2 laser tubes, making them a preferred choice for many users.

By understanding the features and maintenance requirements of glass laser tubes, users can maximize their machine’s performance and achieve high-quality results in their projects. Whether working with wood, acrylic, or leather, investing in the right CO2 glass laser tube will enhance your engraving and cutting experience, delivering precision and efficiency every time.