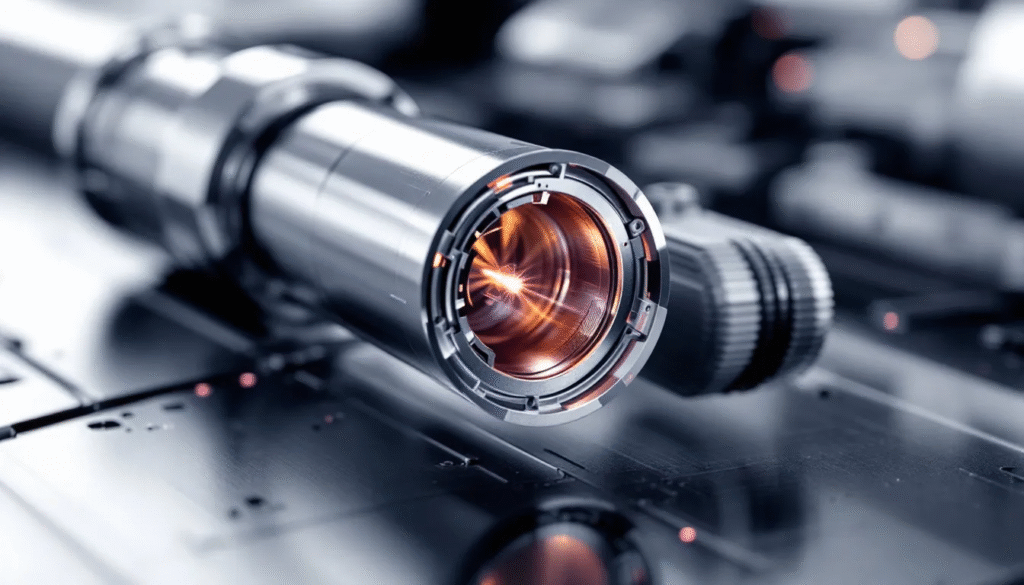

When you buy a CO2 laser tube, it usually works for 1,000 to 3,500 hours. If you use it in the best way, glass tubes can last 3 to 5 years. How long it lasts depends on how you use it and who made it.

- Some people say their tube works for only a few months. Others say it lasts up to three years.

- Most tubes work for about 2,500 to 3,500 hours.

Different brands give different warranties:

| Manufacturer | Warranty Period |

|---|---|

| Parallax Technology, Inc. | 1 year |

| BST Laser | 2 years with lifelong service |

Key Takeaways

- CO2 laser tubes can work for 1,000 to 10,000 hours. How long they last depends on how you use and care for them.

- Cooling is very important. Keep the coolant between 18°C and 25°C. This helps the tube last longer.

- You should clean the tube often. Check for leaks to stop problems early.

- Do not use the tube at full power for a long time. Try to keep the power under 80%. This helps the tube not wear out fast.

- Look for signs that the tube is failing. Weak cutting or strange colors mean you may need a new tube soon.

CO2 laser tube lifespan

Average hours and years

CO2 laser tubes can last for different amounts of time. Most tubes work between 1,500 and 3,000 hours. Some expensive tubes can last up to 10,000 hours. If you use your tube with care and keep it cool, it might last 3 to 5 years. Some people say their tubes last even longer if they take good care of them.

Here is a table that shows how long different brands last:

| Brand/Source | Average Operational Hours | Average Years of Use |

|---|---|---|

| General Reference | 2,000 to 10,000 hours | 3 to 5 years |

| Reputable Brands | 1,000 to 10,000 hours | 2 to 3+ years |

Tip: Take care of your CO2 laser tube to make it last longer. Always follow the instructions from the company that made it.

Many things can change how long your tube works:

- The brand and how well it is made.

- The power level of the tube.

- How much you use it and how high the power is.

- How you cool and take care of the tube.

Some companies say their tubes last 1,000 to 10,000 hours. Most people find their tubes last 1,500 to 3,000 hours. Tubes used at high power or with little care do not last as long.

- Expensive CO2 laser tubes can last 2,000 to 10,000 hours.

- If you keep the tube cool and under 25°C, it will last longer.

- Using your tube at full power all the time makes it wear out faster.

Warranty periods

Different companies give different warranties for CO2 laser tubes. Most companies give a warranty for 6 months to 2 years. Some brands help you for life, but this does not always mean you get a free new tube.

| Manufacturer | Warranty Period |

|---|---|

| Parallax Technology, Inc. | 1 year |

| BST Laser | 2 years with lifelong service |

Sometimes, a tube can stop working early. About 1 out of 100 tubes may break during the warranty. Companies usually give you a new tube if yours breaks during the warranty.

Note: Always read the warranty before you buy a CO2 laser tube. A longer warranty helps you feel safe and protects your money.

Lifespan factors

Usage and power

You control how long your CO2 laser tube lasts by how you use it. If you run your laser often or at high power, you put more stress on the tube. This stress can cause the tube to wear out faster. Overdriving the tube, or pushing it past its rated limit, leads to overheating and damage. You should keep the power below 80% of the tube’s maximum rating. This helps you avoid thermal problems and keeps your tube working longer.

- Frequent use and high power settings can shorten the lifespan of your tube.

- Continuous operation and frequent start-stop cycles add extra wear.

- Overdriving the tube can reduce its life to just a few hundred hours.

- Using a conservative power setting can help your tube last thousands of hours.

If you use an SPT CO2 laser tube below 80W, expect a shorter lifespan. These tubes usually last no more than 3,000 hours. Higher wattage models, such as RECI tubes, can reach up to 10,000 hours.

| Laser Tube Type | Lifespan (Hours) |

|---|---|

| SPT CO2 tubes < 80W | No more than 3,000 |

| Higher wattage models (e.g., RECI) | Up to 10,000 |

Tip: Avoid running your tube at full power for long periods. This simple step can save you money and keep your machine working well.

Cooling and maintenance

Proper cooling and regular maintenance play a big role in tube longevity. You need to keep your tube at the right temperature. For low-power lasers (up to 100W), air cooling with fans works, but water cooling is better for all power levels. Water cooling transfers heat away more efficiently. The best coolant temperature is around 25°C, with small adjustments for the season.

- Use air-cooled heat dissipation for low-power tubes.

- Use water-cooled systems for higher power tubes.

- Keep coolant temperature at 25±2°C.

You should also clean and inspect your tube often. Set the right operating parameters and keep your workspace clean. Check your cooling system to make sure it works well. Replace old parts before they fail. Make a maintenance plan and stick to it. These steps help you catch problems early and keep your tube running for years.

- Clean and inspect your tube regularly.

- Avoid overuse by managing working hours.

- Replace aging parts to maintain performance.

- Develop a maintenance plan for long-term reliability.

Note: Good cooling and regular care help you get the most out of your CO2 laser tube.

Signs of failure

Power loss

Your CO2 laser tube can lose power as it gets older. Sometimes, this happens slowly. Other times, it happens fast. Look for these signs:

- The laser cannot cut or engrave as deep as before.

- You notice less power during normal use.

- The output is much lower than the tube’s rated power.

- The laser beam looks weak or flickers while working.

- You see arcing inside the tube or from the high voltage cable.

When your tube is almost worn out, you may see weaker pulse marks during alignment. Cutting gets harder, and the machine cannot do easy jobs anymore. If the tube stops working, you might see arcing from the high voltage cable. This means you need a new tube.

Tip: If cutting or engraving gets worse, check your tube’s power. Fixing problems early can help you avoid bigger issues.

Visual and physical changes

You can spot physical signs when your CO2 laser tube wears out. These changes are easy to see if you know what to look for. Here is a table with common signs:

| Signs of Failure | Description |

|---|---|

| Difficulty Cutting Materials | The tube cannot cut materials it used to cut easily. |

| Engraving Quality Deteriorates | Engraving looks shallow or unclear, even at higher power. |

| Weak or Flickering Laser Beam | The beam looks dim or changes brightness while working. |

| Physical Damage | Cracks, discoloration, or visible defects show up on the glass tube. |

You may see the glass turn yellow or brown. Cracks or other damage mean the tube is close to breaking. Most tubes show these problems after five to eight years. Performance drops slowly before the tube stops working.

Note: Check your laser tube often for cracks, color changes, or other damage. These signs tell you when it is time to get a new tube.

Extend CO2 laser tube life

Cooling tips

Keeping your CO2 laser tube cool helps it last longer. Good cooling stops the tube from burning out. It also helps your machine work well. Try to keep the water between 18°C and 25°C (64°F to 77°F). If the water is colder than 15°C, water drops can form and hurt the tube. If the water is hotter than 25°C, the tube does not work as well and wears out faster.

| Recommended Temperature Range | What Happens to the Tube |

|---|---|

| 18°C to 25°C (64°F to 77°F) | Works best |

| Below 15°C | Risk of condensation |

| Above 25°C | Lower efficiency, more wear |

Use a cooler that is strong enough for your laser. The cooler should be five times stronger than your laser’s power. A closed chiller with alarms helps you know if something is wrong. Keep the water moving at 2 to 4 liters each minute. This keeps the tube safe from quick changes in temperature and helps it last longer.

Tip: Check your cooling system every time before you use it. Even a small problem can cost a lot to fix.

Cleaning and care

Cleaning and taking care of your CO2 laser tube helps it last longer. Clean the mirrors and lenses every day you use the machine. Use a soft cloth and lens cleaner or denatured alcohol. Do not touch the optics with your hands. Clean and check the focus lens every week or if you see it is not working well.

- Check the coolant often and use distilled water.

- Clean the cooling system so it does not get too hot.

- Keep your work area between 20°C and 32°C and humidity from 35% to 80%.

- Look for leaks in the tube and cooling system.

- Make sure the water pump is working right.

Note: Be gentle when you install or fix the tube. This helps stop cracks and other damage.

Avoid overdriving

Using your CO2 laser tube at full power for a long time can make it wear out fast. Too much heat makes the tube weak and can break it. To stop this, keep the current below the top level. Most tubes should not go over 28mA. Take breaks during long jobs so the tube can cool down.

- Use only 80-90% of the tube’s power.

- Do not turn the tube on and off too much. This keeps the gas inside.

- Use a special chiller to stop the tube from getting too hot.

Tip: Keep your machine in a cool, dry place away from the sun. This stops rust and heat from hurting it.

Your CO2 laser tube can last from 1,500 to 10,000 hours. How long it lasts depends on how you use and care for it. Some things make your tube last longer or shorter. These include how much power you use, how you control the temperature, how you take care of it, how you cool it, and where you use it.

| Key Factor | Description |

|---|---|

| Power usage | Using high power for a long time wears out the tube faster. |

| Temperature control | Big changes in temperature make the tube work less well and not as long. |

| Maintenance habits | Taking care of your tube often stops it from wearing out too soon. |

| Cooling systems | Good cooling keeps the tube from getting too hot and breaking early. |

| Work environment | The place you use your tube, like how hot, wet, or dusty it is, changes how well it works. |

To help your tube last longer, do these things:

- Use the right settings for your tube.

- Clean and check your tube often.

- Make sure your cooling system works well.

- Change old parts before they break.

- Watch how your tube works with tests and warning tools.

Taking care of your tube and checking how it works protects your money. Good habits help you stop problems and make your CO2 laser tube last longer.

FAQ

How do you know when to replace your CO2 laser tube?

You should replace your tube when you see weak cutting, shallow engraving, or a flickering beam. If you notice cracks or discoloration on the glass, the tube has reached the end of its life.

Can you refill a CO2 laser tube?

You cannot refill most glass CO2 laser tubes. Manufacturers seal them at the factory. When the gas runs out or the tube fails, you need to buy a new tube.

Does room temperature affect tube lifespan?

Yes, room temperature matters. High heat or rapid temperature changes can shorten tube life. Keep your workspace between 20°C and 32°C for best results.

What is the best way to store a spare CO2 laser tube?

Store your spare tube in a cool, dry place. Keep it away from sunlight and vibration. Use the original packaging for extra protection.

Tip: Always handle your tube gently. Even small bumps can cause cracks or leaks.