When you pick a CO2 Laser Tube in 2025, look for the right power, good brands, and strong cooling systems. These things help the tube last longer and work better.

People now want more. They look for automation, green designs, and smart features. These things show good quality today.

You need to match the tube type, output, and fit with your work and safety needs. New changes have made performance and reliability even more important.

- Think about these key points:

- Power should fit your material and future plans

- Good cooling helps the tube last longer

- Great support after buying gives you more value

Key Takeaways

- Pick a CO2 laser tube that fits your work. Make sure it has the right power. Check if it fits in your space. This helps you get good results. It also makes the tube last longer.

- Metal or ceramic tubes last a long time. They do not need much care. They give steady power. Glass tubes cost less money. But glass tubes break more easily. They need careful cooling.

- Use the right cooling system for your tube. Use water cooling for strong jobs. Use air cooling for small or portable machines. This keeps your tube safe. It also helps it work well.

- Always check if the tube fits your machine. Make sure it matches your power supply. This stops damage. It helps your machine run smoothly.

- Choose brands and sellers you can trust. Look for good warranties. Make sure they give customer support and training. This protects your money. It helps you do well.

Key Buying Factors

What’s New in 2025

This year, CO2 laser tube technology has changed a lot. Companies now make high-performance systems. These systems give better beam quality and use less energy. Tubes last longer and do not need much fixing.

Tip: Pick tubes with better cooling and smaller size. These features save space and help you work without many stops.

You will see more automation and digital tools. Many tubes now use IoT monitoring and AI process control. You can connect your tube to CNC machines and robots. This setup lets you change settings quickly and work faster.

There is more demand for small and easy-to-move equipment. Companies make tubes that are smaller and have parts you can swap. This helps you fit the tube in small spaces and move it when needed.

Sustainability is very important now. There are new energy recovery modules and eco-friendly cooling. These features help you follow green rules and spend less money.

CO2 laser tubes now have more uses. Medical, packaging, and semiconductor companies need high precision and longer-lasting tools. Companies do research to make special tubes for these jobs.

Prioritizing Your Needs

You need to pick a CO2 laser tube for your job. First, write down what materials you want to use. Some tubes work better with certain materials. Glass tubes are good for small jobs or testing. Ceramic tubes are better for big jobs and work faster.

You should pick the right power output. More power lets you cut thick materials and work quickly. Make sure the tube fits your space and can handle your biggest material.

Note: Always check the cooling system. Good cooling keeps the tube safe and makes it last longer.

Think about all the costs. This includes buying the tube, extra gear, and costs like fixing and power. Tubes that last longer and need less fixing save you money.

Check if the company gives good support. Good service, warranty, and easy-to-find parts help you a lot. Training and tech help are important if you are new to lasers.

You must keep your work area safe. Control the temperature and humidity. Keep the air clean to stop damage. Set the machine right to avoid wearing it out. Clean and check the tube often and follow a plan to keep it working well.

You should test the tube before you buy it. Check your machine, especially if it is old. This step makes sure the tube is right for your needs.

CO2 Laser Tube Types

Glass vs. Metal/Ceramic

You have to pick between glass and metal/ceramic CO2 laser tubes. Each one has good and bad points. You should look at both before you choose.

| Feature | Glass CO2 Laser Tubes | Metal CO2 Laser Tubes |

|---|---|---|

| Material | Borosilicate glass, fragile | Aluminum or steel, highly durable |

| Initial Cost | Lower upfront cost | Higher upfront cost |

| Durability | Less durable, prone to breakage | More durable, longer lifespan |

| Power Output | Less stable, may degrade over time | More consistent and stable output |

| Efficiency | Lower energy conversion efficiency | Higher efficiency, saves energy costs |

| Lifespan | Shorter lifespan | Longer lifespan |

| Maintenance | Requires more frequent maintenance | Requires less frequent maintenance |

| Suitability | Suitable for hobbyists, light tasks | Ideal for industrial, precision tasks |

Glass tubes cost less money at first. They are good for people who do crafts or run small shops. You can use them for simple cutting and engraving. Glass tubes break easily, so you must be careful. They need water cooling, which can be tricky and risky. Most glass tubes last from 6 to 12 months. You might have to buy new ones often.

Metal/ceramic tubes are more expensive when you buy them. They last longer and are stronger. These tubes use air cooling, so you do not worry about water leaks or algae. They give steady power and save more energy. Metal/ceramic tubes are best for factories or jobs that need high accuracy. You can fix or rebuild these tubes, which saves money later.

Tip: Pick metal/ceramic tubes if you want less trouble and fewer stops. If you want to spend less at first and do small jobs, glass tubes might work for you.

Lifespan & Maintenance

You need to know how long each tube lasts and how to take care of it. How long a tube works and how much care it needs will change your costs and how you work.

| Tube Type | Typical Lifespan (hours) | Notes |

|---|---|---|

| Chinese non-branded glass tubes | 1,000 – 1,500 | Very low quality, short lifespan |

| Chinese mid-range glass tubes | 1,500 – 3,000 | Better lens fixing, brass cooling jacket for improved heat dissipation |

| Chinese RECI glass tubes | Up to 10,000 (5,000-7,000 typical) | Sensitive to coolant temperature, reliable insulation, higher quality and power |

| Chinese RF metal tubes | 4-5 times longer than DC glass tubes | More expensive, air-cooled, very durable, less maintenance needed |

Glass tubes can last from 1,000 to 10,000 hours, based on their quality. You must keep the water cool, under 25°C, to make them last longer. You need to check for leaks and clean the cooling system often. Glass tubes use gas that cannot be refilled, so you have to get a new tube when it stops working.

Metal/ceramic tubes can last four to seven years. Some come with a two-year warranty. They use gas you can refill, so they last even longer. These tubes only need air cooling, so taking care of them is easier. You can fix these tubes instead of buying new ones. This means you spend less time and money fixing them.

- Glass tubes can break when shipped or set up.

- You have to buy new glass tubes more often, which means more stops.

- Metal/ceramic tubes can handle shaking and changes in temperature.

- You get steady power and better safety with metal/ceramic tubes.

- You pay less for repairs with metal/ceramic tubes.

You should pick the tube that fits your work. If you have a busy shop or need things to be very exact, metal/ceramic tubes are better. If you want to spend less and just learn or do small jobs, glass tubes might be enough.

Performance & Power

Wattage Options

You have to pick the right wattage for your laser. In 2025, power goes from 40W to over 100W. Each level works for different jobs:

- 40W: This is good for engraving and cutting thin things. You can cut paper or acrylic up to 1/4 inch. Machines like OMtech 40W are great for small shops and hobby use.

- 50W: This gives more power for thicker stuff and faster work. The Vevor 50W is a good mix of price and power.

- 60W, 75W, 80W, 90W, 100W+: These higher wattages cut thick things and work fast. They are best for big jobs and pro use.

If you always use the tube at full power, it will not last long. It is better to get a stronger tube and use it at lower power. This helps the tube last longer. Tubes with more power need better cooling and stronger power supplies.

Tip: Pick the wattage that fits your main jobs. Use high wattage for thick things or if you use the laser a lot. Use low wattage for light work or if you do not use it much.

Mode Stability

Mode stability is about how steady your laser beam is. Tubes with stable modes, like TEM00, give a sharp and focused beam. This helps you make clean lines and detailed engravings. Better lenses help keep the mode steady. This means you get better spots and more accuracy.

A steady mode also makes your machine work well. You get quick results and less time fixing problems. Many companies now use tubes with quasi-TEM00 modes for marking and engraving. This choice gives you better work and saves money over time.

Material Compatibility

You must match the tube’s power and mode to what you want to cut or engrave. Here is a simple guide:

| Material Category | Examples | Notes & Recommendations |

|---|---|---|

| Plastics | Acrylic, PVC, ABS, Polycarbonate | Use high precision for clean edges. Change power for thick pieces. |

| Wood | Oak, Pine, Plywood, MDF | You can do fine cuts and engravings. Change power and speed for thick wood. |

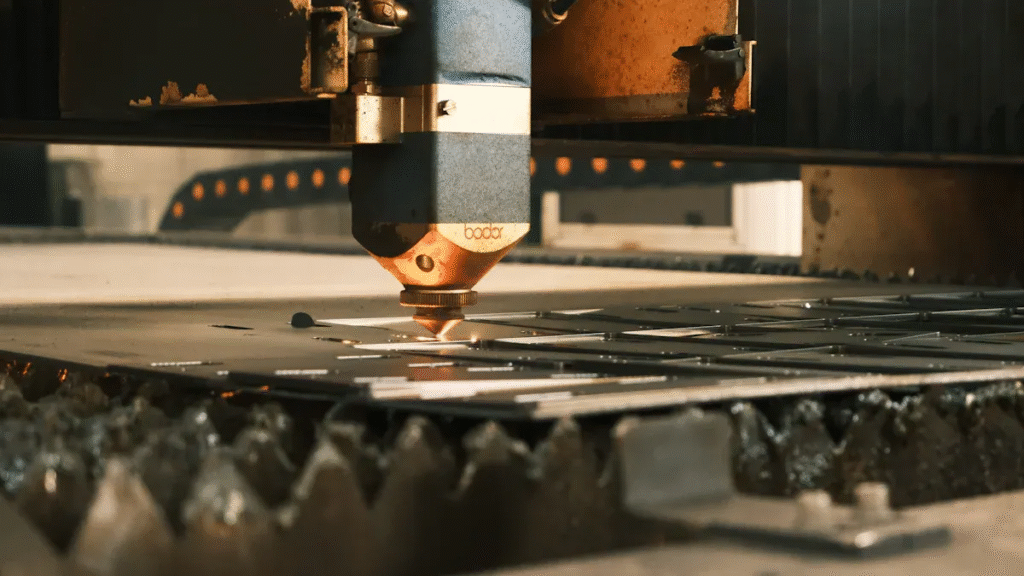

| Metals | Stainless steel, Aluminum, Brass, Copper | Needs more power and extra gases. Use strong cooling for thick metals. |

| Textiles & Fabrics | Cotton, Nylon, Leather | Use less power for smooth edges. Keep the focus sharp for nice patterns. |

| Other Materials | Paper, Cardboard, Rubber, Foam | Change power and speed. Keep the platform clean for best results. |

You should always change power and speed for each material. Thick or shiny things need more power and sometimes extra gases. Clean and check your machine often to get the best results.

CO2 Laser Tube Compatibility

Machine Fit

You need to make sure your new tube fits your machine. Start by checking the length and diameter of your current tube. Measure the space inside your laser machine. Some machines have tight spaces, so even a small difference can cause problems. Look at the mounting brackets and make sure they match the new tube. If you use a tube that is too big or too small, you may damage your machine or get poor results.

Check the footprint of the tube. Some tubes have extra parts or different shapes. Make sure nothing blocks the airflow or cooling system. If you use a metal or ceramic tube, check if your machine supports air cooling or if you need to add new parts.

Power Supply Match

You must match the electrical parts of your CO2 Laser Tube and power supply. Use this checklist to help you:

- Check that the voltage rating of the tube matches your power supply, usually 20-30kV.

- Make sure the connectors are rated for high voltage. Avoid cheap or uncertified connectors.

- Use proper insulation and high-voltage wiring to prevent arcing and keep your setup safe.

- Look at the data plate or specs on your power supply to confirm voltage and current compatibility.

- Buy a power supply that is plug-compatible with your tube model. This makes setup and troubleshooting easier.

- If your connectors or wiring layouts are different, you may need extra parts or adapters.

Tip: Many users measure current to check if the tube works right, since most people cannot measure high voltage directly.

Upgrading Tubes

When you upgrade or replace a tube, follow these steps for a safe and smooth process:

- Unpack the new tube and check for cracks or chips.

- Turn off your machine and open the laser tube bay.

- Remove the bolts and move the top aside with a screwdriver.

- Place the new tube in the mounting seats. Align the cathode toward the reflecting mirror.

- Secure the tube with the fastenings.

- Connect the cathode wire by twisting it with the ignition unit’s cathode wire. Secure it with duct tape.

- Cover the anode wire with a silicone hose. Twist it with the ignition unit’s anode wire. Wrap it with at least four layers of high-voltage tape, then cover again with a silicone hose and tape.

- Attach the water inlet hose to the anode side and the outlet hose to the cathode side.

If you use a Reci tube, connect the ignition unit cathode wire to a bolt on the laser beam output side and wrap the anode wire with extra tape and hose.

Always double-check your connections and cooling before turning on your machine. This keeps you safe and helps your CO2 Laser Tube last longer.

Cooling & Safety

Cooling Methods

You need to choose the right cooling method for your laser system. Cooling keeps your laser tube safe and working well. There are two main types: water-cooled and air-cooled (fan-cooled) systems.

| Aspect | Water-Cooled Systems | Air-Cooled (Fan-Cooled) Systems |

|---|---|---|

| Cooling Mechanism | Uses water to absorb and move heat away | Uses fans to blow air and remove heat |

| Cooling Capacity | High, good for strong lasers and long jobs | Lower, best for small or medium lasers |

| Temperature Stability | Very steady, keeps tube at the right temperature | Less steady, can get too hot with big jobs |

| Noise Level | Quiet operation | Fans make noise |

| Installation Complexity | Needs pumps, pipes, and chillers | Simple, just plug in and use |

| Cost | Costs more at first, but works well for tough jobs | Cheaper to buy and set up |

| Maintenance | Needs regular checks and water changes | Needs less care |

| Portability | Harder to move, has more parts | Easy to move, compact |

| Best Use | High-power, industrial, or precise work | Small jobs, hobby use, or where you need to move it |

Tip: Use water cooling for high-power or long jobs. Pick air cooling for small, portable, or budget-friendly machines.

Safety Features

You must keep safety first when using a laser system. Modern machines include many features to protect you and your workspace.

- Safety interlocks on doors stop the laser if you open the cabinet.

- Laminated safety glass lets you watch your work without risk.

- Always wear goggles made for your laser’s wavelength.

- Never put shiny or reflective objects in the cutting area.

- Use a lock-out key switch to stop anyone from turning on the laser without permission.

- Keep a fire extinguisher and fire blanket close by.

- Make sure you have a good fume extraction system to remove smoke and gases.

- Only trained people should use the laser.

- Warning labels remind you about laser dangers.

- Never change or remove safety features.

Note: Know how to shut down the laser quickly in an emergency.

Maintenance Tips

Regular care helps your laser system last longer and work better. Follow these steps to keep your machine in top shape:

- Clean the mirrors every week and the lens every day.

- Check the power output often with a power meter.

- Use an ammeter to make sure you do not run the tube too hard.

- Keep the cooling water between 15°C and 25°C.

- Use distilled water and change it often to stop buildup.

- Calibrate the power supply to keep voltage steady.

- Clean optics with a lint-free cloth and special cleaner.

- Check gas pressure and seals once a year.

- Support the tube at the right points and do not twist it after setup.

- Run the laser at 70–80% power for most jobs.

- Let the machine warm up and cool down for 5–10 minutes before and after use.

- Keep the room between 5–35°C and humidity below 60%.

Tip: Buy quality parts and check your system often to catch problems early.

Brands & Buying

Top Brands

You should pick a brand that is well-known in 2025. The best companies use new technology and give good help. The table below shows how top brands are different:

| Aspect | EFR Laser Tubes | RECI Laser Tubes |

|---|---|---|

| Excitation Method | Electric current excites gas | Heat from light waves excites gas |

| Beam Quality | Stable output, excellent beam quality | Pure, evenly distributed laser beam |

| Applications | Engraving, cutting, marking on many materials | Precision work, medical devices, scientific tools |

| Cost-effectiveness | Lower initial and maintenance costs | Higher cost, superior quality, long-term stability |

| Cooling Requirement | Needs water chillers for best results | Needs water chillers for best results |

Top brands use smart calibration and automation. Their machines change settings by themselves and make fewer mistakes. These brands have strong power choices and can cut many things. You can trust their products for small shops or big factories.

Supplier Tips

You need a supplier who does more than sell you a tube. Look for these things:

- Knows trusted brands like Reci and EFR.

- Good prices and checks quality as an official seller.

- Safe shipping with strong boxes and insurance.

- Quick replacement if your tube breaks.

- Helpful customer service before and after you buy.

- Many ways to pay.

- Wants you to be happy and delivers on time.

- Has spare parts and things you need in stock.

- Can upgrade systems and gives software updates.

- Clear warranty and good help after you buy.

Tip: Ask about training and tech help before you buy. Good suppliers help you set up and keep your system working.

Bundles & Deals

You can save money and time with a bundle. Many suppliers sell packages with the laser tube, power supply, and extras. These bundles may have software, longer warranties, and special things like rotary attachments or auto-focus.

| Bundle Component | Description / Options |

|---|---|

| Base Laser Tube | 40W sealed tube |

| Upgrades | Longer-life tube, higher wattage options |

| Accessories | Coolbox, fume extractor, rotary attachments |

| Software | Locally hosted web software included |

| Warranty | 1 year standard, extensions available |

| Additional Features | 3D camera, auto-focus, removable floor |

| Value Impact | Bundles improve convenience, performance, and cost-effectiveness |

Some suppliers, like LightObject, sell tubes and extras one by one. You might need to buy power supplies and cooling systems yourself. Always check if the bundle fits your needs and machine. Bundles make buying easier and give you more for your money.

Cost & Support

Price Ranges

You should know how much laser systems cost. Prices in 2025 change by power, type, brand, and where you live. Basic tubes for thin things and simple CNC jobs start at $15,000. Middle models with more power and some automation cost $50,000 to $100,000. The best tubes for thick things and robots can cost $150,000 or more. European brands and top laser sources add 20-30% to the price. North America and Europe are 10-20% more expensive than Asia-Pacific.

| Price Tier | Laser Power Range | Typical Price Range (USD) | Key Features and Applications | Brand and Regional Price Impact |

|---|---|---|---|---|

| Entry-Level | 1.5kW – 3kW | $15,000 – $40,000 | Thin materials, basic CNC, manual loading, basic software | Chinese brands standard; Europe/NA higher by 10-30% |

| Mid-Range | 4kW – 6kW | $50,000 – $100,000 | Medium-thick materials, auto loading, advanced software | Brand premium, IPG adds 20-30% |

| High-End | 6kW – 12kW+ | $150,000 and above | Thick materials, robotics, high precision, multi-axis cutting | Europe brands 20-30% more; regional price differences persist |

Many things change the price. Newer machines, famous brands, and better specs cost more. How much energy it uses, tube life, spare parts, and labor also matter. Prices can go up if raw materials or rules change. Automation, green features, and custom parts can make it cost more.

Tip: Always look at the total cost, not just the first price. Think about fixing, energy, and new parts.

Warranty

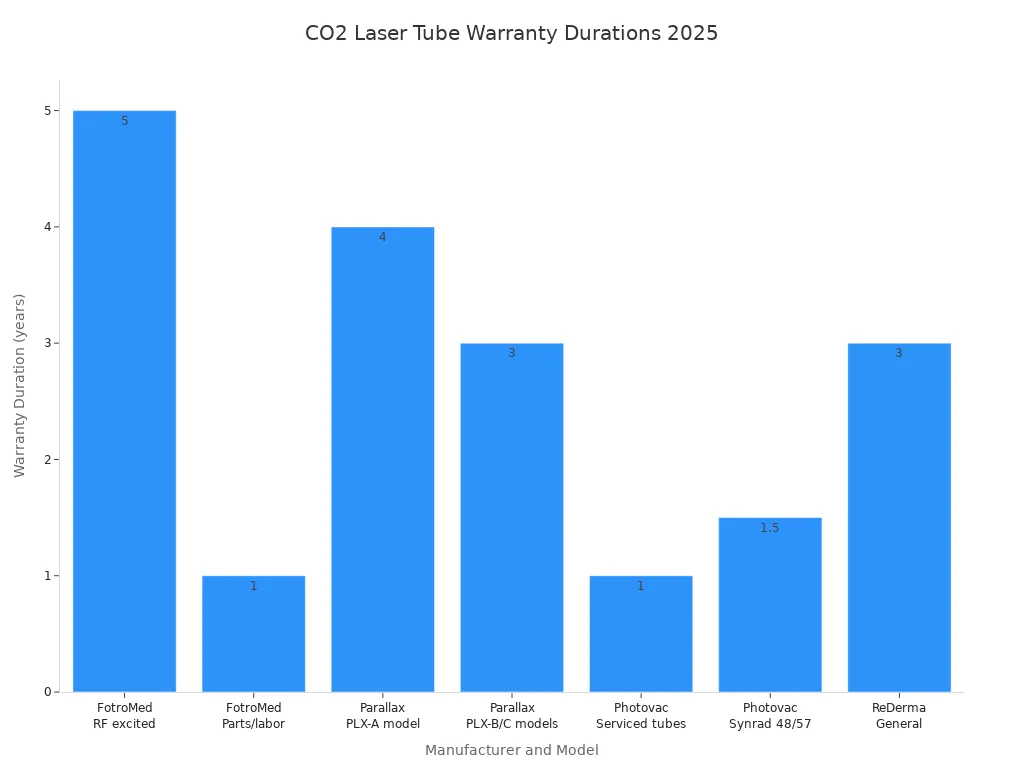

A warranty helps protect your money. Top companies give good warranties in 2025. FotroMed gives 5 years for RF excited tubes and 1 year for parts and labor. Parallax Technology gives 4 years for PLX-A and 3 years for PLX-B and PLX-C. Photovac Laser covers fixed tubes for 1 year and Synrad series for 18 months. ReDerma machines have a 3-year warranty.

| Manufacturer | Model/Type | Warranty Duration |

|---|---|---|

| FotroMed | RF excited CO2 laser tube | 5 years |

| FotroMed | Parts and labor | 1 year |

| Parallax Technology | PLX-A model CO2 laser tube | 4 years (output power) |

| Parallax Technology | PLX-B and PLX-C models | 3 years (output power) |

| Photovac Laser | Serviced tubes (reprocess) | 1 year |

| Photovac Laser | Synrad 48-series & 57-series | 18 months |

| ReDerma machines | General | 3 years |

Longer warranties mean the company trusts their product. You feel safer and worry less about surprise costs. Always check what the warranty covers, like labor, parts, and power.

Customer Service

Good customer service makes owning a laser easier. The best brands have expert teams and real spare parts. Some companies answer in 24 hours and use IoT to find problems from far away. This help means less waiting and longer tube life.

- RECI is known for great service and free swaps for problems.

- CDWG gives good help and long tube life.

- YL has good prices but not as much service.

- EFR and JOY do not share much about their service.

You get help around the world, both in person and online. Free tuning and power checks are extra benefits. Always pick a seller with strong tech help and quick answers.

Note: Good service and warranty keep your machine safe and working well.

When picking a CO2 Laser Tube, think about what you need and how much you can spend. Also, think about what you want in the future. Make a list that includes the technical details, if the supplier is trusted, and if they help you after you buy. Try out the machines before you buy one. Look at the warranty so you do not get any surprises. Good customer service, easy ways to upgrade, and strong compatibility make your machine last longer. Talk to suppliers you trust and plan to take care of your machine. Doing these things helps you get the best use and value for many years.

FAQ

What is the best way to extend the life of my CO2 laser tube?

You should keep the cooling system clean and use distilled water. Run your tube at 70–80% power for most jobs. Clean the optics often. Check for leaks and replace worn parts quickly.

How do I know if a tube will fit my machine?

Measure the length and diameter of your current tube. Check your machine’s mounting brackets and space. Review the manufacturer’s compatibility chart before you buy. Ask your supplier for advice if you have doubts.

Can I upgrade my power supply when I change tubes?

You can upgrade your power supply if the new tube needs more voltage or current. Always match the tube’s specs with the power supply. Use certified connectors and high-voltage wiring for safety.

What materials can I cut with a CO2 laser tube?

| Material | Suitability |

|---|---|

| Acrylic | Excellent |

| Wood | Excellent |

| Leather | Good |

| Metal | Needs special setup |

| Fabric | Good |

You can cut acrylic, wood, leather, and fabric. Cutting metal needs extra equipment.

Do I need special training to use a CO2 laser tube?

You should get basic safety training before you use a CO2 laser tube. Learn about setup, cooling, and emergency shutdown. Many suppliers offer free guides or online courses. Training helps you avoid mistakes and keeps you safe.