A laser cutting machine lens is essential for precise cutting and engraving. This article covers types of lenses, choosing the right one, and maintenance tips. Understanding these aspects will boost your machine’s performance and longevity.

Key Takeaways

- Understanding the significance of laser cutting machine lenses is essential for precision in both cutting and engraving applications.

- Selecting the right lens type based on material and application is crucial; options like achromatic, plano-convex, and aspheric lenses have specific advantages.

- Regular maintenance, proper cleaning, and correct alignment of laser lenses are vital for optimizing performance and achieving high-quality cuts.

Understanding Laser Cutting Machine Lenses

Laser lenses play a pivotal role in manipulating laser beams for various applications, including cutting and engraving. These optical components focus, diverge, or converge light, which is crucial for achieving the precision required in laser cutting projects. The condition and design of the laser lens significantly impact the efficiency and accuracy of the cutting process. A well-maintained lens ensures cleaner edges and finer cuts, making it an indispensable part of any laser cutting machine.

However, laser lenses are susceptible to damage or contamination from scratches, dust, or molten residue. This makes careful handling and regular maintenance essential to preserve optimal laser performance.

The design of a laser lens is integral to how precisely a laser beam can be focused and shaped. A well-designed lens enhances overall laser performance by minimizing optical aberrations, keeping the laser beam sharp and consistent. This is particularly important for tasks that demand high precision, such as intricate laser engraving and detailed material cutting.

The right laser lens can transform a project from mediocre to a masterpiece. Mastering the nuances of laser lenses is essential for laser cutting. Here are the different types of laser lenses and their specific applications.

Laser Cutting Machine Components

A laser cutting machine is a sophisticated system made up of several essential components, each playing a critical role in the laser cutting process. At the heart of the machine is the laser source, which generates the powerful laser beam used for cutting, engraving, and marking a wide variety of materials. This laser beam is precisely manipulated by a series of optical components—including mirrors and lenses—to achieve the desired cutting effect.

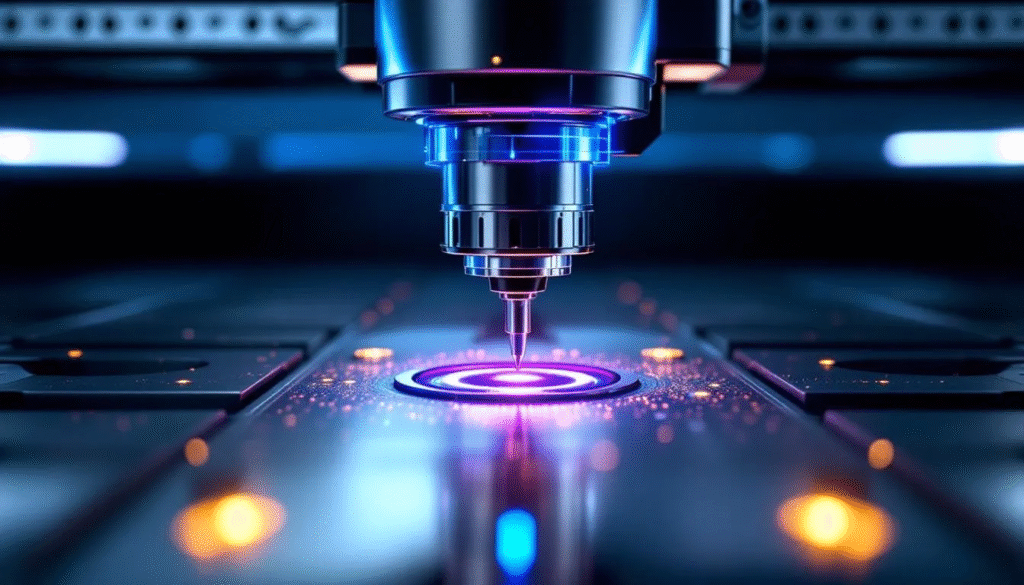

One of the most vital optical components is the focusing lens. This lens concentrates the laser beam to a tiny focal point, dramatically increasing the energy density at that spot. The result is the ability to make highly accurate and clean cuts, even on intricate designs. The focusing lens is housed within the laser head, which is responsible for delivering the laser beam to the material’s surface. The design and quality of the laser head, as well as the lens it contains, have a direct impact on the overall laser performance and the quality of your material cutting.

The control system of a laser cutting machine, which includes both software and hardware, regulates the movement of the laser head, adjusts the laser power, and manages other critical parameters. This ensures that the laser beam follows the correct path and maintains the optimal focal distance for each specific material and thickness. The focal distance signifies the distance from the lens to the focal point where the laser beam achieves its smallest diameter. For example, a shorter focal length lens is typically used for cutting thin materials with fine detail, while a longer focal length lens is better suited for thicker materials, providing a deeper focus and cleaner edges.

Regular maintenance of all laser cutting machine components is essential for sustaining high performance and preventing issues such as rough edges, uneven cuts, or reduced efficiency. Cleaning the lens surface with specialized tools like lens tissue helps remove dust and contaminants that can scatter the laser beam and degrade cut quality. It is crucial to keep the focusing lens clean to maintain a high transmittance. Checking the alignment of the laser beam and ensuring all optical components are free from scratches or damage will help maintain precision and extend the lifespan of your equipment.

Safety is another crucial factor when working with laser cutting machines. Always follow recommended safety guidelines, such as wearing protective eyewear and ensuring proper ventilation, to protect yourself and your workspace from potential hazards.

To get the most out of your laser cutting projects, it’s important to discover the optimal combination of machine components and settings. This includes selecting the right laser lens and focal length for your application, adjusting the focal distance to match the material thickness, and maintaining all components in top condition. Additionally, factors such as laser power, material properties, and cutting speed must be carefully balanced to achieve the best results without damaging the machine or the material.

For more detailed information on your specific laser cutting machine components and how to optimize their performance, consult your user manual or visit the manufacturer’s website. Staying informed about the latest advancements in laser cutting technology and best practices for maintenance will help you stay ahead in a competitive industry and ensure your business continues to deliver high-quality, precise results.

In summary, understanding and maintaining the key components of your laser cutting machine—including the laser lens, laser head, and control system—is essential for achieving superior accuracy, efficiency, and quality in all your laser cutting and engraving projects. By prioritizing regular maintenance and making informed choices about your machine’s components, you can unlock the full potential of your laser system and ensure long-term success in your business.

Types of Laser Lenses

Laser lenses are tailored to modify beam properties for specific tasks, making them essential tools in cutting and engraving. Achromatic lenses, for instance, are designed to reduce chromatic aberration, providing sharper images across various wavelengths. These lenses are particularly useful in applications requiring high precision and clarity.

Plano-convex lenses are widely used in laser systems for focusing and cutting due to their ability to effectively converge laser light. These lenses are flat on one side and convex on the other, with one side being flat and the other side convex, making them ideal for achieving a concentrated laser beam.

In contrast, double-convex lenses, with their two outward-curving surfaces, are commonly employed in applications that require beam expansion and collimation. Meniscus lenses, which have a combination of convex and concave surfaces, reduce spherical aberration and are suitable for precise beam shape.

Aspheric lenses, with their complex profiles, minimize aberration and enhance the accuracy of laser systems, especially in cutting and medical applications. Cylindrical lenses, on the other hand, are specialized for correcting astigmatism in laser beams, ensuring uniform focus in different orientations. Familiarity with these options helps in selecting the best lens for your specific cutting process.

Materials Used for Laser Lenses

The materials used for laser lenses are crucial in determining their performance and durability. Optical glass and zinc selenide (ZnSe) are commonly used materials for laser cutting focusing lenses. ZnSe is particularly effective in CO2 laser systems, as it is designed to accommodate a wide range of wavelengths by using materials and coatings optimized for those wavelengths, providing excellent optical clarity. Low power and high power lenses can utilize the same high-quality ZnSe material.

Quality assurance is vital when selecting ZnSe lenses to avoid low-quality products that could compromise performance. High-quality ZnSe lenses are manufactured using superior material standards. Ensuring that the ZnSe is sourced from reputable suppliers can prevent issues related to contamination and poor-quality cuts. Additionally, selecting the appropriate material for a focusing lens is essential to optimize performance and prevent damage during the laser cutting process. The price of ZnSe laser focusing lenses starts from $99.00.

Different coatings on laser lenses can further enhance their functionality. These coatings are tailored to optimize transmission rates for specific laser wavelengths, improving overall laser performance for various applications. Knowing the materials and coatings used in laser lenses helps make informed decisions, enhancing the precision and efficiency of your projects.

How to Choose the Right Focusing Lens

Selecting the appropriate focusing lens is crucial for achieving the desired results in cutting and engraving. Consider the following when choosing a lens:

- Different sizes of focusing lenses vary in suitability based on specific requirements.

- Larger lenses extend the focus tolerance, which is beneficial for cutting through thicker materials.

- Different types of lenses are better suited for cutting versus engraving applications.

Therefore, it is typically important to discover the right lens based on the principle of your specific needs. A longer focusing lens reduces energy density but allows for cutting thicker materials due to greater focal depth.

Material selection is another important factor. Fused silica and BK7 glass are preferred materials for fiber and diode laser lenses due to their optical clarity and thermal stability. The size of the lens also plays a significant role in cutting performance. Larger lenses provide better focus tolerance, while shorter focal lengths result in a sharper focal spot but limit the depth of field, affecting cutting precision with different materials.

Conducting a focus test on scrap material ensures accuracy in your lens configuration. This process helps you verify that the selected lens setup meets your cutting requirements and allows for adjustments if necessary. You may need to adjust the focal distance to optimize cutting depth, accuracy, and speed. Rechecking cutting parameters is necessary after replacing the focusing lens. These factors will guide you in selecting the right focusing lens for your projects.

Impact of Focal Length on Cutting Quality

Focal length plays a pivotal role in determining the focus spot size and depth of focus, both of which are crucial for achieving high-quality cuts:

- A smaller focal length results in a smaller focused spot diameter.

- This smaller spot diameter increases energy density at the focal point.

- Increased energy density enhances cutting precision.

- A shorter focal distance results in a smaller beam diameter, which increases energy density and creates a more aggressive beam. A smaller beam diameter results in higher energy density, which creates a more aggressive laser beam for cutting.

- This is particularly beneficial for cutting thinner materials where fine details are required.

The maximum intensity of the laser beam occurs at the specified focal distance, leading to a higher energy density of energy and more efficient cutting. However, longer focal distances extend the depth of field, which can be advantageous for cutting thicker materials where a deeper focus is needed to achieve a clean cut. Longer focal distances result in an extended depth of field, allowing straighter cut edges in thicker materials. Laser power is essential in this process.

Improper focus can lead to issues like surface roughness and burrs on the edges of cut materials, indicating misalignments in the cutting process. Therefore, maintaining the proper laser head height according to material thickness is essential for maximizing focal efficiency and achieving superior cut quality. Knowing the impact of focal length aids in fine-tuning your cutting process for optimal results.

Setting Up and Aligning Your Laser Lens

Correctly setting up and aligning your laser lens is crucial for achieving precise cuts and engravings. Follow these steps:

- Ensure the laser cutting machine is connected and powered on.

- Verify that all components are clean.

- Extract the focusing lens from the mirror frame, handling it carefully to avoid contamination.

Place the protective film with the convex side facing up, ensuring that the convex side of the lens is also facing upward. This positioning is vital for optimal focusing and performance. Once the lens is in place, insert the lens tube and nozzle, adjusting the focal distance to suit the material being cut.

Proper alignment ensures that the laser beam is accurately directed onto the material, resulting in cleaner, more precise cuts. Following these steps ensures optimal lens performance and minimizes the risk of errors during cutting.

Maintenance and Cleaning of Laser Lenses

Regular maintenance and cleaning of laser lenses sustain optimal cutting performance. Key recommendations include:

- Use 99% isopropyl alcohol for cleaning, as it evaporates quickly and leaves no residue.

- Use a high-quality lens-cleaning kit.

- Avoid abrasive materials to prevent scratches on the lens.

- To clean the lenses, use laboratory-grade soft cotton balls dipped in appropriate solvents like acetone or high-purity alcohol.

When cleaning the lens, follow these steps:

- Use a compressed air bulb to remove dust from the surface.

- Gently wipe the lens in a clockwise direction.

- Start from the center and move towards the edges to avoid scratches.

- Handle lenses by their edges or wear gloves to avoid contact with oils. Use lint-free gloves when handling laser lenses to reduce the risk of contamination.

- Note: Ensure the lens is completely dry before reinstalling it to prevent damage or residue buildup.

Regular maintenance extends the lifespan of your lenses and keeps your laser system performing at its best. Key practices include:

- Daily cleaning for frequent use or post-job cleaning for lighter use.

- Regularly inspecting lenses for cracks or discoloration.

- Using lens caps when the machine is not in operation to protect lenses from dust and physical damage.

- Store lenses in protective cases in a clean, dry environment to prevent contamination when not in use.

Common Issues with Laser Lenses and How to Solve Them

Issues with laser lenses can significantly affect the cutting process. Contaminants of focusing and collimating lenses is often caused by splatter generated during cutting. Laser lenses are very delicate components highly susceptible to damage such as scratches. This contamination can reduce the precision and quality of the cuts, leading to wider kerf widths and rough edges.

Signs that a focusing lens may need replacement include indentations, film peeling, and scratches on the lens surface. A blurry laser lens negatively impacts the cutting process by decreasing precision and quality, making it crucial to address any signs of wear or damage promptly.

Regularly inspecting and cleaning your lenses helps solve these issues. Replacing worn or damaged lenses ensures that your laser cutting projects maintain high standards of precision and quality.

Enhancing Laser Performance with Proper Lens Care

Proper lens care enhances laser performance and extends equipment lifespan. Regular maintenance of laser lenses helps sustain optimal laser cutting performance by preventing contamination and ensuring clear, precise cuts. Using protective gas and adequate gas flow can further prevent contamination of the lenses during the cutting process, contributing to overall safety.

Regular cleaning and proper handling of laser lenses are crucial for maintaining their effectiveness. Investing time in regular maintenance and using proper cleaning techniques ensures peak performance of your laser cutting machine, leading to superior results.

Summary

In summary, mastering precision in laser cutting involves understanding the types of laser lenses, choosing the right materials, and maintaining them properly. By following the guidelines for lens selection, setup, and maintenance, you can enhance the performance of your laser cutting machine and achieve superior results in your projects. The lifespan of a focusing lens varies, typically lasting around 2400 hours of use before requiring replacement. Implementing these practices will not only extend the lifespan of your lenses but also ensure that your laser cutting projects are executed with the highest level of accuracy and efficiency.

Frequently Asked Questions

Why is the condition of a laser lens important?

The condition of a laser lens is crucial because it directly impacts the precision and efficiency of the cutting process, resulting in cleaner edges and finer cuts. Regular maintenance ensures optimal performance and quality.

What are achromatic lenses used for?

Achromatic lenses are primarily used to reduce chromatic aberration, resulting in sharper images across different wavelengths, particularly in laser applications. This enhancement in image clarity is essential for precise optical performance.

Why is ZnSe used in CO2 laser systems?

ZnSe is utilized in CO2 laser systems for its ability to transmit a wide range of wavelengths effectively, enhancing the performance and efficiency of the laser. This characteristic makes it a preferred choice for such applications. ZnSe laser lenses are available for commercial use.

How does focal length impact cutting quality?

Focal length directly impacts cutting quality by determining the focus spot size and depth of focus, thereby influencing the precision of cuts on various materials. A shorter focal length typically yields finer cuts, while a longer focal length may enhance cutting efficiency on thicker materials.

What is the recommended cleaning agent for laser lenses?

The recommended cleaning agent for laser lenses is 99% isopropyl alcohol, as it evaporates quickly and leaves no residue. This ensures the lenses remain clear and unobstructed for optimal performance.