Maintaining your أنبوب ليزر CO2 is essential to ensure the laser machine operates efficiently and delivers accurate cutting and engraving results. Proper CO2 laser tube maintenance is crucial for all types of equipment, including laser cutters, laser cutting machines, and other machines, as it not only extends the laser tube’s lifespan but also helps save money by preventing costly repairs and downtime. In this article, we will explore the critical role of regular maintenance tasks, cleaning processes, and proper care techniques to keep your laser system—and the lasers within it—operating reliably and prolong their operational longevity.

Understanding the Importance of CO2 Laser Tube Maintenance for Your Laser System

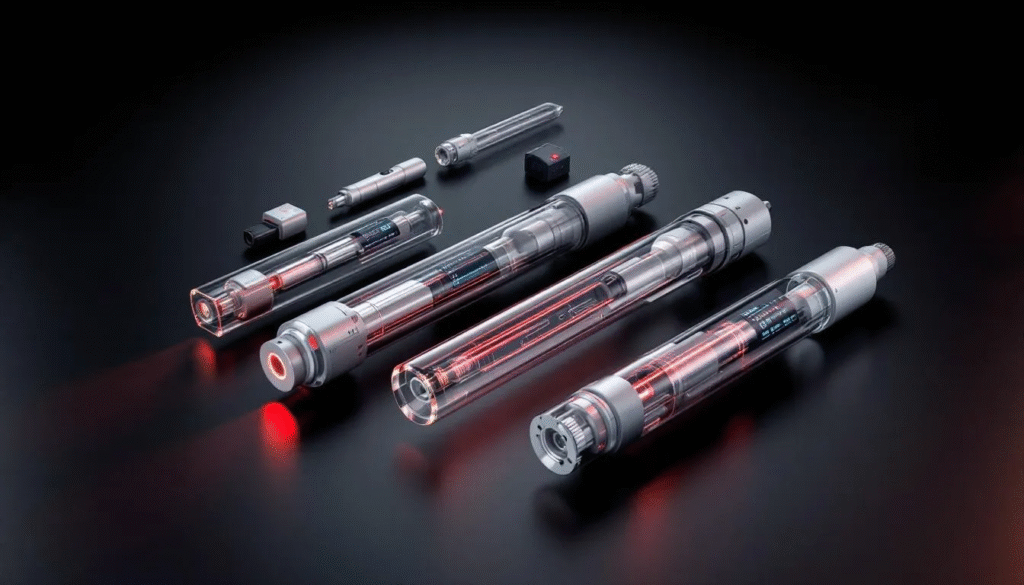

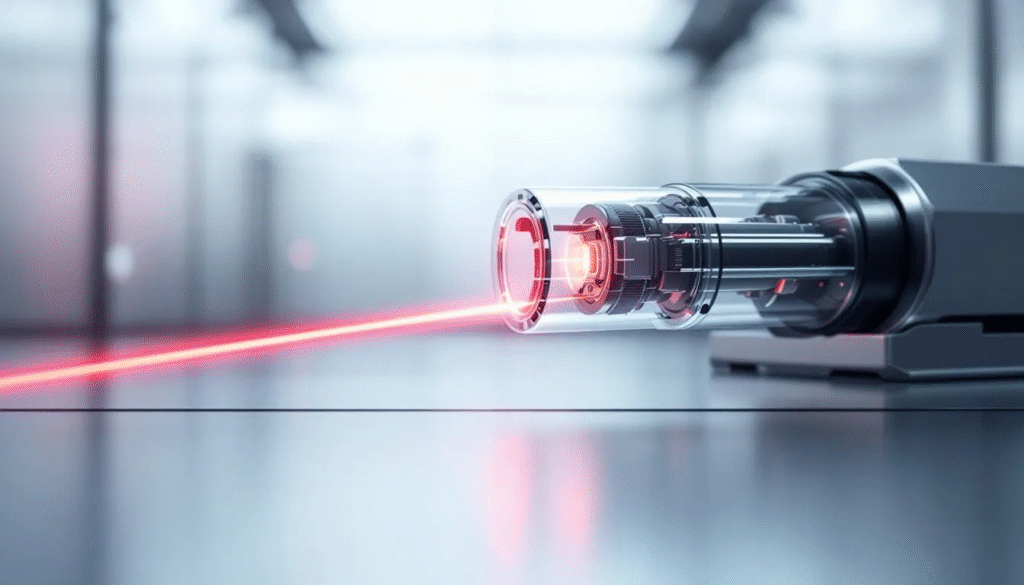

إن أنبوب ليزر CO2 is the heart of any laser cutting machine or laser engraving machine. It generates the laser beam that performs the cutting or engraving work. Over time, dirt, debris, and other contaminants can accumulate on the glass laser tube and surrounding components, which significantly reduce the laser power and efficiency. Glass tubes are commonly used in CO2 laser machines due to their affordability and versatility, but they require regular maintenance to ensure reliable operation. The average service life of a CO2 glass laser tube is about 3,000 hours, meaning it typically needs to be replaced approximately every two years. Dirty optics, including the laser focus lens (the focal lens is a critical optical component that should be kept clean to ensure optimal laser performance) and laser mirrors, can also degrade the quality of the laser beam, leading to inaccurate cutting and poor performance.

Regular maintenance is necessary to ensure optimal performance and prevent overheating, which can damage the tube and shorten its service life. By following preventive maintenance routines, you can keep your laser system working efficiently and avoid unexpected breakdowns.

Key Components to Maintain in Your Laser System: Glass Laser Tube, Cooling System, and Optics

Several parts of the laser machine require attention during CO2 laser tube maintenance. The glass tube itself must be kept clean and free from cracks or discoloration. The laser focus lens and laser mirrors play a critical role in directing and focusing the laser beam, so regularly cleaning these optics with an appropriate cleaning solution is vital. Use a clean, soft cloth and appropriate cleaning solution to gently wipe mirrors and lenses, ensuring they remain free of dirt and contaminants.

The cooling system, which often includes a water chiller, water pump, and water inlet, is another crucial component. Proper cooling maintains the laser tube within the optimal temperature range, preventing overheating and ensuring the tube operates at full power. Using distilled water mixed with an appropriate antifreeze in the cooling system helps avoid mineral buildup and prevent corrosion, maintaining the system’s efficiency and prolonging the tube’s lifespan. It is important to add antifreeze to prevent freezing and damage to the water chiller and laser tube during cold weather or periods of inactivity.

Traditional glass laser tubes differ from radio frequency (RF) laser tubes, which use radio frequency energy for excitation. RF tubes may have different maintenance requirements compared to glass tubes.

Power Settings and Usage Patterns: How Operation Affects Tube Longevity

The way you operate your laser machine has a direct impact on the lifespan of your CO2 laser tube. Running your laser at high power settings for long periods can significantly reduce the tube’s service life, as excessive power generates more heat and stress within the tube. To ensure peak performance and extend the life of your laser tube, it’s important to adjust power settings based on the material and thickness you’re working with. Whenever possible, use lower power settings and avoid continuous operation at maximum power. Allow the tube to cool down between sessions to prevent overheating and wear. Regularly monitor the laser tube’s power output and adapt your usage patterns to prevent unnecessary wear. By optimizing how you use your CO2 laser, you can help your machine and tube work efficiently for years to come.

Regular Maintenance Tasks for Your CO2 Laser Tube Maintenance Routine

To keep your CO2 laser tube in peak condition, you should perform several regular maintenance tasks. First, clean the glass laser tube gently using a soft cloth and a lens cleaning solution or an appropriate cleaning solution designed for optical components. Avoid using harsh chemicals like hydrofluoric acid, which can damage the glass tube.

Next, regularly clean the laser focus lens and laser mirrors to remove dirt, dust, and other contaminants. This cleaning process helps maintain the laser power and ensures accurate cutting. In dusty environments, cleaning should be done more frequently to prevent debris buildup.

Additionally, monitor the cooling system closely. Check the water pump and water inlet for any blockages, and ensure the water chiller is functioning correctly to keep the laser tube within the optimal temperature range. Regularly replace the water in the cooling system with purified or distilled water to prevent mineral buildup. Regularly clean the cooling system to prevent dust, algae, and other contaminants from clogging the system, which can reduce cooling efficiency.

If you notice signs of wear, diminished cutting performance, or a dimming laser beam, the laser tube should be replaced. Replacing the tube at the right time is crucial for maintaining optimal machine performance.

Alignment Checks: Ensuring Accurate Laser Performance

Accurate alignment of the laser beam is essential for achieving precise cuts and engravings with your laser machine. If the laser beam is misaligned, it can cause uneven wear on the laser tube and compromise the quality of your work. To ensure optimal performance, perform regular alignment checks, especially after moving your machine or if you notice a drop in cutting or engraving accuracy. Use alignment tools to verify the path of the laser beam and make adjustments as needed. Promptly correcting any misalignment helps protect the laser tube and other components, ensuring your machine delivers consistent, high-quality results.

Tips to Extend the Lifespan of Your Glass Laser Tube Through Proper CO2 Laser Tube Maintenance

Proper care and maintenance can significantly increase the service life of your glass laser tube. Avoid running the laser at full power continuously; instead, adjust the power settings according to the task to prevent unnecessary strain on the tube. For DC laser tubes, maintaining stable direct current power helps avoid fluctuations that can damage the tube.

Ensure the laser system’s air assist is working correctly to remove smoke and debris from the cutting area, which helps keep the optics clean. Regularly inspect the laser tube for signs of wear or damage, and replace it promptly if any issues arise.

By following these top tips and regularly monitoring your laser cutting machine’s performance, you can enjoy long periods of reliable operation and save money on repairs and replacements.

Working Environment: Creating Optimal Conditions for Your CO2 Laser Tube

The working environment plays a critical role in the efficiency and longevity of your CO2 laser tube. Factors such as temperature, humidity, and dust can all affect the tube’s performance. For optimal performance, maintain a stable temperature range between 20°C and 32°C (68°F to 90°F) and keep humidity levels between 35% and 80% relative humidity (non-condensing). Using air conditioning and a dehumidifier can help control these conditions, while regular cleaning and dust removal will prevent contaminants from affecting the laser tube. By creating and maintaining an ideal working environment, you can significantly enhance the efficiency and service life of your CO2 laser tube.

Turn-On and Turn-Off Procedures: Protecting Your Laser Tube During Operation

How you power your laser cutting machine on and off can have a lasting impact on the service life of your glass laser tube. Frequent on/off cycles can cause rapid temperature changes, which may affect the sealing sleeve and compromise the gas tightness of the tube. To protect your laser tube, avoid turning the machine on and off repeatedly during short breaks. Instead, only power down the laser cutting machine during longer pauses, such as lunch or extended downtime. Following proper turn-on and turn-off procedures helps maintain the integrity of your glass laser tube and supports long-term, reliable laser cutting performance.

Troubleshooting Common Issues with CO2 Laser Tubes

Even with regular maintenance, CO2 laser tubes can develop issues over time. Common signs of trouble include weaker laser output, inconsistent cutting or engraving quality, and visible wear on the tube. Dirty optics, such as the laser focus lens and mirrors, can also lead to performance problems. To address these issues, regularly clean the laser tube and optics with a soft cloth and an appropriate cleaning solution. Monitor the cooling system to ensure it is functioning properly and preventing overheating. Electrical spikes can also damage the tube, so check your power supply and connections regularly. By staying vigilant and addressing problems as soon as they arise, you can prevent further damage, extend the lifespan of your CO2 laser tube, and keep your laser system operating at optimal performance.

Conclusion: Ensuring Peak Performance and Longevity with CO2 Laser Tube Maintenance

CO2 laser tube maintenance is a critical aspect of operating a laser cutting or engraving machine efficiently. By regularly cleaning the glass tube, lenses, and mirrors, maintaining the cooling system, and monitoring power settings and temperature, you can ensure your laser system works at peak performance. Proper maintenance not only improves cutting accuracy but also significantly reduces the risk of overheating and extends the laser tube’s lifespan. Adopting these maintenance practices will help you get the most out of your laser machine, keeping it working efficiently for years to come.