عندما يتعلق الأمر بماكينات القطع والنقش بالليزر، فإن أنبوب ليزر ثاني أكسيد الكربون 150 واط يبرز كمكون قوي وفعال. تستكشف هذه المقالة الميزات الرئيسية ونصائح التركيب وممارسات الصيانة واعتبارات الشراء المتعلقة بأنبوب ليزر ثاني أكسيد الكربون بقدرة 150 وات لمساعدتك على اتخاذ قرار مستنير.

مقدمة في تقنية الليزر

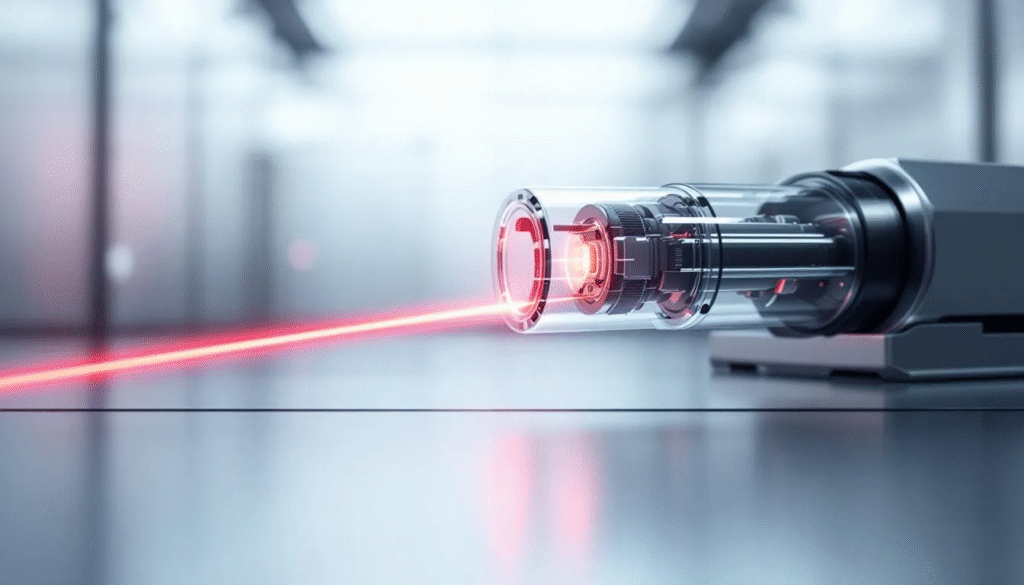

لقد أصبحت تقنية الليزر حجر الزاوية في صناعات تتراوح من التصنيع إلى الفنون الإبداعية، وذلك بفضل دقتها وكفاءتها التي لا مثيل لها. ويقع أنبوب الليزر في صميم كل ماكينة قطع أو نقش بالليزر الذي يولد ضوء الليزر القوي المطلوب للعمل التفصيلي. يشتهر أنبوب ليزر ثاني أكسيد الكربون على وجه الخصوص بقوته العالية وموثوقيته، مما يجعله خيارًا شائعًا لتطبيقات النقش والقطع.

لتحقيق النتائج المثلى وضمان رضا العملاء، من الضروري فهم كيفية عمل أنبوب الليزر ومصدر الطاقة وعدسة الليزر معًا داخل الماكينة. يلعب كل مكون دوراً حيوياً: أنبوب الليزر ينتج الضوء، ومصدر الطاقة يوفر الطاقة اللازمة، وعدسة الليزر تركز الشعاع للتشغيل الدقيق.

إن إتقان هذه العناصر هو المفتاح لإطلاق الإمكانات الكاملة لنظام ليزر ثاني أكسيد الكربون الخاص بك، سواء كنت تعمل على نقوش معقدة أو إنتاج واسع النطاق.

فهم أنبوب ليزر ثاني أكسيد الكربون بقدرة 150 وات

A أنبوب ليزر ثاني أكسيد الكربون 150 واط هو أنبوب ليزر عالي الطاقة يُستخدم عادةً في ماكينات الليزر المختلفة لقطع ونقش ووسم المواد المختلفة. يولد أنبوب الليزر ضوء الليزر اللازم للتشغيل الدقيق والفعال. وهو يعمل عن طريق إثارة غاز ثاني أكسيد الكربون داخل الأنبوب، الذي ينتج شعاع ليزر بالأشعة تحت الحمراء. ثم يتم توجيه هذا الشعاع من خلال عدسة ليزر و مرآة عاكسة لتركيز الضوء على المادة.

للحصول على الأداء الأمثل، من المهم التأكد من الموضع الصحيح لأنبوب الليزر بحيث تصطدم بقعة الليزر بمنتصف المرآة العاكسة. يساعد التموضع الصحيح على الحفاظ على محاذاة دقيقة ومعالجة الليزر بكفاءة.

تعني القدرة التي تبلغ 150 واط أن أنبوب الليزر هذا يوفر توازنًا بين قوة القطع واستهلاك الطاقة، مما يجعله مناسبًا للتطبيقات الصناعية والهواة على حد سواء. إن أنبوب الليزر يجب إقرانها بشكل صحيح مع مزود الطاقة لضمان استقرار الجهد والتردد، وهو أمر بالغ الأهمية لأداء الأنبوب وطول عمره.

مواصفات أنبوب ليزر ثاني أكسيد الكربون CO2

عند اختيار أنبوب ليزر ثاني أكسيد الكربون بقدرة 150 واط، فإن فهم مواصفاته أمر بالغ الأهمية لضمان التوافق والأداء الأمثل. عادةً ما يتم تصنيع أنبوب ليزر ثاني أكسيد الكربون القياسي بقدرة 150 واط من زجاج البورسليكات المتين، ويبلغ طول الأنبوب القياسي 150 واط (1850 مم) وقطره 80 مم، ويبلغ وزنه الصافي حوالي 55 رطلاً (25 كجم). يعمل هذا الأنبوب عند طول موجي يبلغ 10,640 نانومتر، ويوفر طاقة ثابتة مع ثبات يبلغ ±5%.

يختلف العمر التشغيلي للأنبوب بناءً على استخدام الطاقة: يمكن أن يؤدي تشغيله بأدنى طاقة (10-40%) إلى ما يصل إلى 12000 ساعة، بينما قد يؤدي تشغيله بإعدادات طاقة أعلى (70-100%) إلى تقليل العمر الافتراضي إلى حوالي 7000-8000 ساعة. يعد التركيب السليم أمرًا ضروريًا - يساعد توصيل الطرفين الموجب والسالب بشكل صحيح وضمان دوران الماء عبر خط المياه بالكامل على منع انفجار الأنابيب والتشغيل غير السليم. من خلال الالتزام بهذه الإرشادات، يمكن للمستخدمين زيادة كفاءة وطول عمر أنبوب ليزر ثاني أكسيد الكربون بقدرة 150 واط إلى أقصى حد، مما يضمن التشغيل السلس لجميع مشاريع ليزر ثاني أكسيد الكربون الخاصة بهم.

المكونات الرئيسية ووظائفها

إن أنبوب الليزر يعمل جنبًا إلى جنب مع العديد من المكونات لتحقيق أفضل النتائج. إن مزود الطاقة يوفر الجهد والتيار اللازمين لإثارة الغاز داخل الأنبوب. إن المطابقة المناسبة بين مصدر الطاقة ومواصفات الأنبوب تمنع حدوث مشاكل مثل التآكل المبكر أو التعطل.

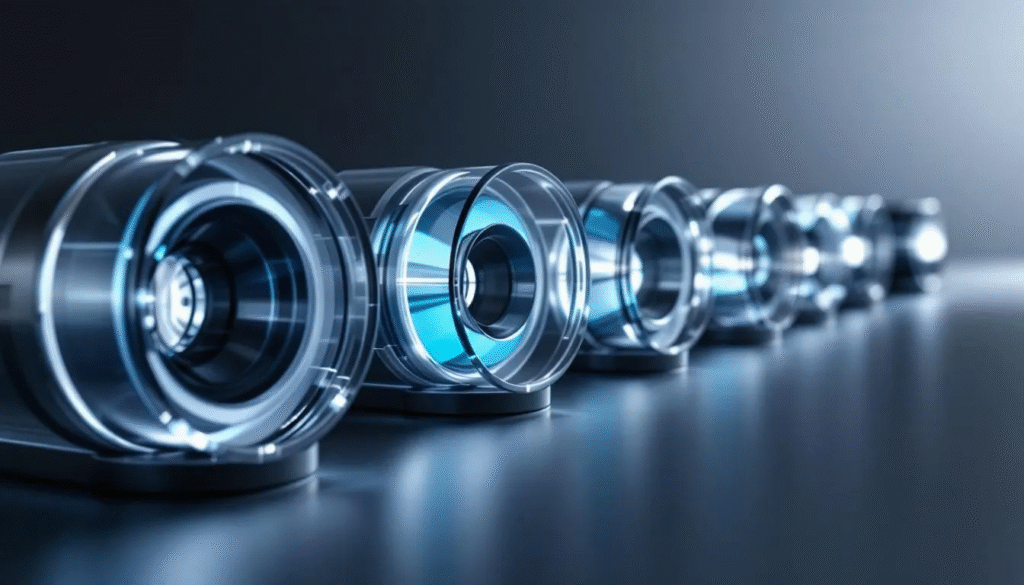

إن عدسة ليزر تركز ضوء الليزر المنبعث من الأنبوب. يعد اختيار العدسة الصحيحة بناءً على قوة الأنبوب ومتطلبات الماكينة أمرًا ضروريًا لتحقيق عمليات القطع والنقش الدقيقة. بالإضافة إلى ذلك، فإن مرآة عاكسة دورًا حاسمًا في توجيه شعاع الليزر على طول المسار البصري للآلة.

للحفاظ على كفاءة الأنبوب، يجب أن يكون نظام خط المياه بأكمله سليماً ويعمل بشكل صحيح. وهذا يشمل مبرد الماء و دوران الماء التي توفر تبديدًا فائقًا للحرارة. يعد التدفق الفعال لمياه التبريد أمرًا ضروريًا للحفاظ على درجة الحرارة المثلى، وضمان أداء ليزر مستقر، وإطالة عمر أنبوب الليزر. التبريد الفعال يمنع ارتفاع درجة حرارة الأنبوب مما قد يتسبب في تلفه أو يقلل من عمره الافتراضي.

مصدر الطاقة والتوافق

يعد مصدر الطاقة الموثوق به أمرًا أساسيًا للتشغيل الآمن والفعال لأي أنبوب ليزر CO2. يجب مطابقة مصدر الطاقة بعناية مع متطلبات الجهد والتردد للأنبوب للحفاظ على أداء مستقر وإطالة عمر خدمة الأنبوب. يمكن أن يؤدي استخدام مزود طاقة غير متوافق إلى تشغيل غير سليم أو انخفاض الإنتاج أو حتى تلف دائم لأنبوب الليزر.

عند اختيار مزود الطاقة، لا يجب مراعاة المواصفات الفنية فحسب، بل يجب أيضًا مراعاة العوامل العملية مثل تكلفة الشحن ولوجستيات التسليم. إن ضمان شحن مصدر الطاقة وأنبوب الليزر وتركيبهما بشكل صحيح يقلل من مخاطر التلف أثناء النقل والإعداد. ومن خلال اختيار مصدر طاقة مصمم خصيصًا لأنبوب ليزر ثاني أكسيد الكربون الخاص بك، يمكنك تجنب المخاطر التشغيلية وضمان تشغيل جهازك بسلاسة منذ البداية.

عدسة الليزر والتركيز البؤري

تُعد عدسة الليزر مكونًا مهمًا للغاية في أي ماكينة ليزر، وهي مسؤولة عن تركيز ضوء الليزر على المادة من أجل القطع أو النقش الدقيق. ومن خلال العمل جنبًا إلى جنب مع المرآة العاكسة، يجب محاذاة عدسة الليزر وصيانتها بشكل صحيح لضمان الحصول على أعلى جودة للنتائج. الفحص والتنظيف المنتظم ضروريان لمنع تراكم الغبار، الذي يمكن أن يؤدي إلى تدهور جودة الشعاع ويشكل خطرًا على الأنبوب والعدسة.

يوفر نظام التركيز البؤري المصمم جيدًا أيضًا تبديدًا فائقًا للحرارة، مما يحمي الأنبوب من السخونة الزائدة ويطيل عمره الافتراضي. بالنسبة للمشترين، من المهم مراعاة ليس فقط الجوانب التقنية للعدسة ونظام التركيز البؤري ولكن أيضًا الأمور العملية مثل طرق الدفع، بما في ذلك التعامل الآمن مع تفاصيل بطاقة الائتمان، وفهم سياسة الإلغاء الخاصة بالبائع. من خلال إعطاء الأولوية للعناية المناسبة بالعدسة وتصميم النظام المناسب، يمكن للمستخدمين تحسين أداء الماكينة وتقليل احتياجات الصيانة وتحقيق رضا أكبر للعملاء عبر مجموعة من التطبيقات.

نصائح التركيب والصيانة

يعد التركيب الصحيح أمرًا حيويًا لتحقيق أقصى قدر من الأداء والمتانة لأنبوب ليزر ثاني أكسيد الكربون بقدرة 150 وات. عند توصيل الأنبوب بالماكينة، تأكد من أن إيجابية و سلبي تتم مطابقة الأطراف بشكل صحيح لتجنب المشاكل الكهربائية. قم بتوصيل أسلاك الكاثود والأنود بشكل آمن، وتأكد من توصيل مدخل ومخرج المياه بشكل صحيح بنظام خط المياه بالكامل دون أي تسريبات أو انفجار الأنابيب.

الفحص المنتظم لنظام التبريد ضروري للكشف عن فقاعات الهواء أو خطوط المياه المسدودة أو المسارات البصرية التي يمكن أن تعيق تدفق المياه. هذه المشاكل يمكن أن تعرض للخطر تبديد فائق للحرارة ويتسبب في ارتفاع درجة حرارة الأنبوب. باستخدام مبرد الماء المصممة لأنابيب الليزر تساعد في الحفاظ على درجة حرارة مستقرة، وهو أمر ضروري لإخراج ليزر ثابت.

ضبط موضع أنبوب الليزر والمكونات البصرية، مثل عدسة ليزر و مرآة عاكسةيضمن بقاء ضوء الليزر مركزًا ودقيقًا بشكل دوري. يمكن أن يتراكم الغبار والحطام على هذه المكونات، لذا يوصى بتنظيفها بعناية أثناء الصيانة الروتينية.

تأكد من إكمال جميع خطوات التركيب والإعداد لضمان التشغيل السليم والسلامة.

اعتبارات الشراء لأنبوب ليزر ثاني أكسيد الكربون بقدرة 150 واط

عند شراء أنبوب ليزر ثاني أكسيد الكربون بقدرة 150 واط CO2، يجب أخذ عدة عوامل في الاعتبار. يجب مراعاة ما يلي السعر يختلف حسب العلامة التجارية والمواصفات والملحقات المضمنة مثل مزود الطاقة و عدسة ليزر. بعض العلامات التجارية ذات السمعة الطيبة، مثل فيجو ليزر فيجوتقدم أنابيب بضمانات تضمن الجودة وطول العمر.

يتحمل المشتري مسؤولية الإبلاغ عن أي أضرار، وفهم تكاليف الشحن، والإلمام بشروط الضمان. يجب على العملاء فحص الطرد بعناية عند التسليم واتباع الإجراء الصحيح في حالة تلف الطرد. ملحوظة: من المهم تقديم مطالبة على الفور في حال وجود أي مشاكل في الشحنة أو الطرد، والاحتفاظ بالوثائق المناسبة لمطالبات الضمان والشحن. قد تختلف سياسات الشحن حسب المنطقة؛ على سبيل المثال، قد تختلف تفاصيل وأسعار الشحن في الولايات المتحدة الأمريكية.

من المهم التحقق من المخزون التوافر و التوصيل التواريخ المدرجة لتخطيط الجدول الزمني لمشروعك بفعالية. بالإضافة إلى ذلك، استفسر عن تكلفة الشحنخاصة إذا كان الطلب دولياً، حيث يمكن أن يؤثر ذلك على التكلفة الإجمالية.

للدفع، يقبل العديد من البائعين العديد من طرق الدفعبما في ذلك بطاقات الائتمان. ومع ذلك، تأكد دائمًا من تفاصيل بطاقة الائتمان يتم التعامل معها بشكل آمن وفهم البائع سياسة الإلغاء في حال احتجت إلى تغيير طلبك أو إلغائه.

إذا كنت تتوقع تحقيق الشراء المتكرر أو المؤجلومناقشة الخيارات مع المورد لاحتمالية التفاوض على شروط أو خصومات أفضل. فهم السعر العادي وأية صفقات ترويجية يمكن أن تساعدك في الحصول على صفقة.

استكشاف الأخطاء وإصلاحها واستبدالها

على الرغم من التركيب والصيانة الدقيقين، قد تنشأ مشكلات في أنبوب ليزر ثاني أكسيد الكربون بقدرة 150 وات. وتشمل المشاكل الشائعة انخفاض طاقة الليزر، أو عدم انتظام إخراج ضوء الليزر، أو عدم بدء التشغيل بشكل صحيح. تشير هذه الأعراض غالبًا إلى الحاجة إلى الفحص أو الاستبدال.

إذا ظهر على الأنبوب علامات تآكل أو تلف، مثل التشققات أو تغير اللون، فمن المستحسن استبداله على الفور لتجنب إتلاف مكونات الماكينة الأخرى. عند استبدال الأنبوب، تأكد من مطابقة الوحدة الجديدة لمواصفات الماكينة الخاصة بك، بما في ذلك الطول والطاقة والجهد والتردد.

قم دائمًا بإجراء فحص شامل التفتيش الأنبوب الجديد والمكونات المرتبطة به قبل التركيب. تأكد من أن مرآة عاكسة و عدسة ليزر نظيفة ومحاذاة بشكل صحيح لتحقيق الأداء الأمثل.

يُعد أنبوب ليزر ثاني أكسيد الكربون بقدرة 150 وات مكونًا أساسيًا لماكينات القطع والنقش بالليزر، حيث يوفر طاقة ودقة عالية. يضمن لك فهم مبادئ العمل والمكونات الرئيسية ومتطلبات الصيانة الحصول على أفضل أداء وطول العمر الافتراضي لنظام الليزر الخاص بك. عند الشراء، ضع في اعتبارك عوامل مثل السعر والضمان وتكلفة الشحن وموثوقية الموردين للقيام باستثمار ذكي. إن التركيب السليم والفحص المنتظم والاستبدال في الوقت المناسب سيحافظ على تشغيل جهاز الليزر الخاص بك بسلاسة وكفاءة.

للمزيد من المعلومات التفصيلية عن أنابيب ليزر ثاني أكسيد الكربون ونصائح الصيانة، يمكنك زيارة فيجو ليزرالموقع الرسمي. بالإضافة إلى ذلك، للحصول على إرشادات حول سلامة الليزر والتشغيل السليم، فإن معهد الليزر الأمريكي موارد قيّمة.