The heart of every CO2 laser machine lies in its laser tube – a precision-engineered component that transforms electrical energy into focused light capable of cutting through wood, engraving acrylic, and processing dozens of materials. Whether you’re running a small shop specializing in custom crafts or managing an industrial operation, understanding CO2 laser tubes is essential for achieving optimal performance and maintaining profitable operations.

This comprehensive guide covers everything you need to know about laser tubes, from basic specifications to advanced installation techniques. You’ll discover how to match power ratings to your specific applications, ensure proper maintenance for maximum lifespan, and make informed purchasing decisions that support your business goals. By the time you finish reading, you’ll have the knowledge to select, install, and maintain CO2 laser tubes with confidence.

At Feiju Laser, we pride ourselves on delivering high-quality CO2 laser tubes designed to meet the diverse needs of our customers. Our products combine advanced engineering with rigorous testing to ensure better performance, longer lifespan, and reliable operation in all types of laser engraving and cutting machines.

What Are CO2 Laser Tubes

CO2 laser tubes are gas-filled glass cylinders that generate focused laser beams for cutting and engraving materials through a carefully controlled process of electrical excitation. These sealed units contain a precise mixture of carbon dioxide, nitrogen, and helium gases at low pressure, typically 10-30 Torr, which creates the active medium necessary for laser generation. The primary components of a CO2 laser system include a sealed tube, an energy source, and mirrors for light generation and amplification. CO2 laser tubes are used for both engraving and cutting applications, and are available in various power levels to accommodate different needs for cutting and engraving.

The fundamental process begins when electrical energy excites nitrogen molecules to a metastable vibrational state. These energized molecules efficiently transfer their energy to CO2 molecules, creating a population inversion that enables stimulated emission at approximately 10.6 micrometers wavelength. This wavelength falls in the mid-infrared range and is strongly absorbed by most organic materials, making CO2 laser systems ideal for processing wood, paper, leather, acrylic, and many other non-metallic materials.

CO2 laser tubes generate an intense, invisible infrared beam (wavelength around 10.6 micrometers) by electrically exciting a gas mixture (CO2, Nitrogen, Helium) inside a sealed tube. This wavelength is highly absorbed by most non-metallic materials, making CO2 lasers very effective for working with wood, plastics, leather, glass, fabrics, and some metals. They can be used for both engraving and cutting applications.

Available in power ranges from 20W to 160W, depending on application requirements, these laser tubes serve as the core component of CO2 laser machines used across manufacturing, crafting, and industrial applications. The power output directly correlates with cutting speed and material thickness capability, while the beam quality determines the precision and edge finish of your cuts.

Modern CO2 laser tubes generate coherent light through electrical excitation of the gas mixture, with helium playing a crucial role in heat removal and assisting in depopulating lower vibrational levels through collisions. This allows for continuous-wave operation essential for production environments where consistent performance matters most.

Types and Specifications

The laser tube market offers several distinct construction types, each designed for specific applications and performance requirements. Understanding these differences helps you make informed decisions when selecting equipment for your laser engraver or cutting system.

Glass tube construction represents the most common type, with typical lengths ranging from 700mm to 1650 mm, depending on power requirements. A 40W tube typically measures 700mm in length with a 50mm diameter, while higher-power units like 80W tubes extend to 1250-1600mm with 80mm diameters. Standard diameters include 50mm, 55mm, 65mm, and 80mm based on power output, with larger diameters accommodating the increased bore size needed for higher current operation.

Metal-head tubes offer enhanced cooling and longer lifespan for high-power applications where continuous operation is required. These units integrate metal end caps with specialized mirror mounting systems that provide superior thermal stability and reduced alignment drift over time. The metal construction also allows for more robust cooling connections, supporting the higher heat loads generated in production environments.

RF-excited tubes provide more stable output and reduced maintenance requirements compared to traditional DC-excited glass tubes. Radio frequency excitation at megahertz frequencies creates a more uniform discharge across the gas mixture, resulting in better beam quality and faster modulation capabilities. These systems excel in high-speed marking applications where rapid on-off cycling is essential.

Pre-connected wiring options are available for simplified installation, particularly beneficial for shop owners who need to minimize downtime during tube replacement. These systems include properly rated high-voltage cables and safety interlocks that ensure secure connections while protecting operators from electrical hazards.

At Feiju Laser, we offer a range of CO2 laser tubes, including glass, metal-head, and RF metal-ceramic types, all engineered to meet rigorous quality standards and provide superior durability and performance in your laser systems.

The choice between tube types often comes down to balancing initial cost against operational requirements. Glass DC tubes offer the lowest purchase price and work well for general cutting applications, while RF metal-ceramic tubes command premium prices but deliver superior performance in demanding production environments.

Power Ratings and Performance

Power ratings directly determine the cutting capabilities and application range of your laser system, making proper selection crucial for achieving desired results. Understanding the relationship between power, material thickness, and cutting speed helps optimize both productivity and operational costs.

20W-40W tubes are suitable for light engraving on wood, acrylic, and leather applications where precision matters more than speed. These lower-power units excel at detailed engraving work, creating fine text and intricate patterns on materials up to 3mm thick. They also handle paper cutting for packaging applications and light cardboard processing for prototyping work.

60W-80W tubes represent the sweet spot for many small to medium shops, capable of cutting acrylic up to 10mm thick and wood up to 6mm with reasonable production speeds. This power range handles most commercial engraving projects while providing sufficient cutting capability for signage work, craft production, and custom manufacturing. Operating current typically remains below 20 mA for these power levels, ensuring good tube longevity.

100W-130W tubes tackle more demanding applications, cutting acrylic up to 19mm (3/4 inch) thick and processing thicker hardwoods for furniture components and architectural elements. These systems support higher production volumes and can handle multiple-pass cutting for extremely thick materials. Operating current should not exceed 25 mA for optimal lifespan.

150W-160W high-power tubes serve industrial cutting applications and processing of thick materials where speed and throughput are paramount. These units can cut through 20mm+ acrylic in single passes and handle continuous production schedules. However, they require careful current management, with recommended maximums of 30 mA for normal operation.

Beam quality and stability are maintained through advanced gas mixture ratios that often include catalysts to extend operational life. Quality tubes specify TEM00 mode operation with M² values between 1.0 and 1.5, ensuring tight focus capabilities essential for precision work. The frequency response of DC glass tubes typically reaches 5 kHz for pulsed operation, though practical modulation speeds may be lower depending on the power supply and control system.

Applications and Material Compatibility

The versatility of CO2 laser tubes makes them indispensable across numerous industries, with each application demanding specific power levels and operational characteristics. Understanding material compatibility helps ensure you select the right tube for your intended use case.

Acrylic cutting and engraving represents one of the most popular applications, with CO2 laser systems delivering clean, polished edges up to 20mm thickness without additional finishing. The 10.6-micrometer wavelength is strongly absorbed by acrylic, creating smooth cuts that often appear flame-polished. Lower power settings enable surface engraving for awards, signage, and decorative elements.

Wood cutting and engraving covers a broad range of materials, including plywood, MDF, hardwood, and bamboo. Power requirements vary significantly with species and thickness – softwoods cut easily with moderate power, while dense hardwoods may require maximum settings for anything beyond surface engraving. Proper ventilation is essential as wood processing generates significant smoke and particulates.

Leather processing serves fashion, automotive, and craft industries with applications ranging from pattern cutting to decorative engraving. The organic nature of leather makes it highly compatible with CO2 wavelengths, though natural variations in density require some experimentation to determine optimal settings. Synthetic leathers often behave differently from natural materials.

Paper and cardboard cutting supports packaging and artistic applications where precision matters more than speed. Light cardboard cuts easily with minimal power, while corrugated materials may require higher settings to penetrate multiple layers cleanly. These applications often benefit from higher-frequency pulsing to minimize charring.

Fabric cutting revolutionizes textile manufacturing and custom garment production by providing precise cuts without fraying. Synthetic fabrics like polyester respond well to CO2 processing, while natural fibers may require careful parameter adjustment to prevent excessive burning. The sealed edge created by laser cutting often eliminates the need for hemming in many applications.

Glass and ceramic engraving offer personalization and decorative opportunities, though these materials require different techniques than cutting applications. Surface etching creates permanent markings for awards, bottles, and architectural elements. The process removes material through controlled ablation rather than cutting.

Stone materials, including marble, granite, and slate, respond to CO2 engraving for architectural signage and memorial applications. While cutting thick stone isn’t practical with typical tube powers, surface engraving creates permanent, weather-resistant markings that traditional methods can’t match.

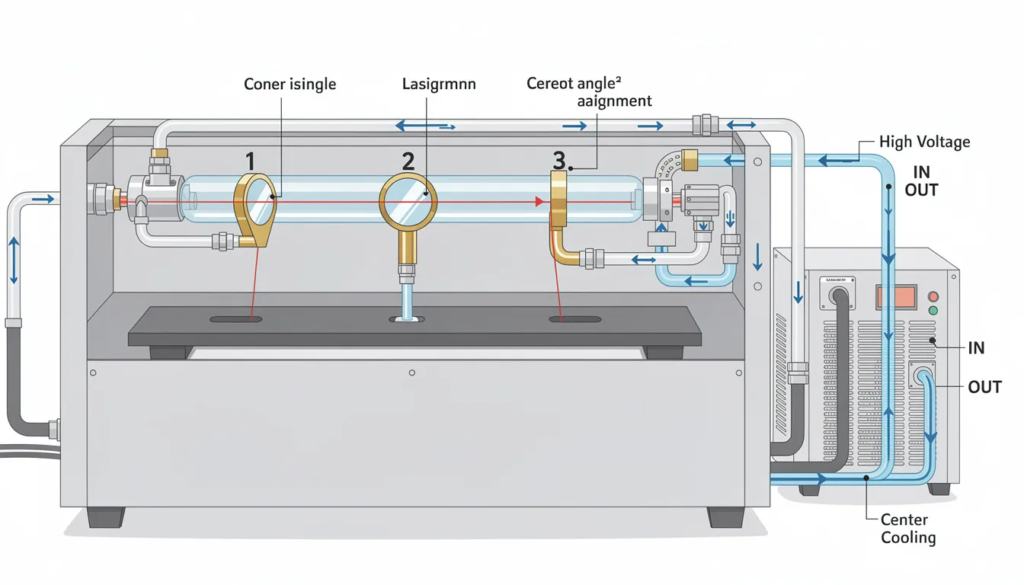

التثبيت والإعداد

Proper installation of your CO2 laser tube directly impacts performance, safety, and operational lifespan. The precision required for optimal beam alignment demands attention to detail and understanding of the underlying physics involved in laser operation.

Proper alignment with mirrors and focusing lens is critical for optimal performance, as even small misalignments can reduce power delivery to the workpiece by 50% or more. The beam path must enter the center of each mirror and focusing lens to maintain beam quality and prevent thermal damage to optical components. Start alignment with the tube output and work systematically through each mirror in the path.

Water cooling systems require flow rates of 2-4 liters per minute to maintain proper tube temperature during operation. Install the inlet connection at the bottom of the tube and the outlet at the top to ensure complete circulation and prevent air bubble formation. Use distilled water or specialized coolants to prevent mineral buildup that can reduce heat transfer efficiency over time.

High-voltage power supply connections typically operate at 15kV-30kV, depending on tube power, making proper electrical safety paramount. The anode connection goes to the high reflector, while the cathode connects through current monitoring circuits. Always use properly rated cables and maintain adequate clearance from grounded surfaces to prevent arcing.

Mounting brackets must accommodate thermal expansion during operation, as glass tubes can expand several millimeters when heated to operating temperature. Use adjustable mounts that allow for this movement while maintaining proper alignment. Over-constraining the tube can create stress points that lead to premature cracking.

Safety interlocks and protective housing are required for operator protection, given the invisible nature of CO2 laser radiation at 10.6 micrometers. Emergency stop circuits should immediately shut down both the laser power and the beam path. Proper enclosure design prevents both direct beam exposure and reflection hazards that could cause serious injury.

Temperature monitoring systems help ensure optimal performance by maintaining water coolant between 15-25°C. Temperatures below this range can cause condensation issues, while higher temperatures reduce laser efficiency and accelerate tube aging. Many systems include automatic shutdown protection when temperatures exceed safe limits.

At Feiju Laser, we provide detailed installation guides and expert support to ensure your CO2 laser tube is set up correctly for maximum efficiency and safety.

Maintenance and Lifespan

Understanding maintenance requirements and expected lifespan helps optimize your investment while ensuring consistent performance throughout the tube’s operational life. Proper care can significantly extend usable hours, while poor maintenance can halve expected lifespan. The expected lifespan of 8000-12000 hours for quality glass tubes under normal operation represents the industry standard, though actual performance varies with operating conditions. Premium tubes with catalysts and advanced gas mixtures may exceed these numbers, while budget options might fall short. RF metal-ceramic tubes typically offer much longer service lives, often 20,000+ hours.

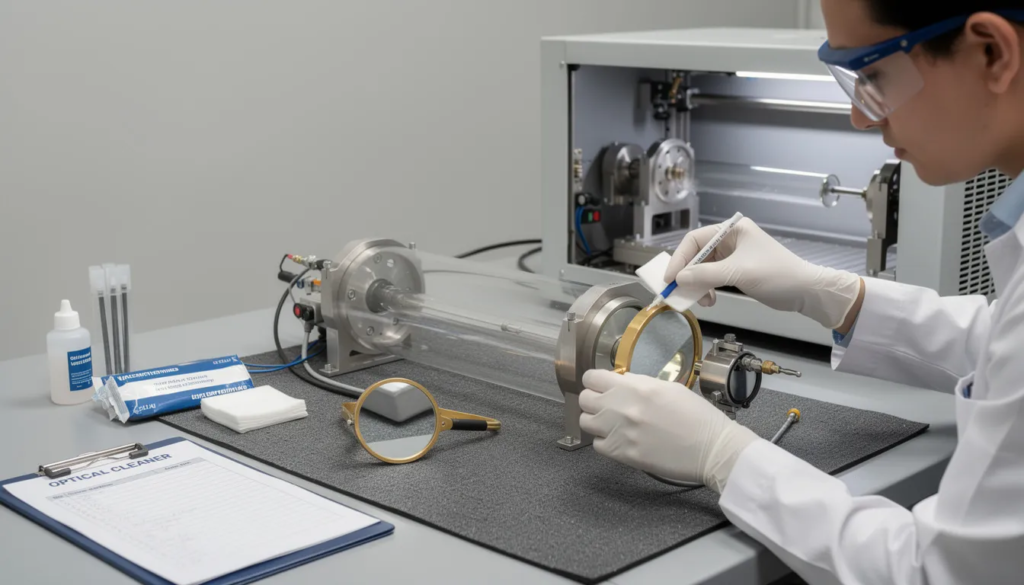

Regular cleaning of tube ends and mirrors every 100-200 hours of use prevents contamination buildup that degrades beam quality and reduces power output. Use appropriate solvents like methanol or acetone with lint-free wipes, taking care not to scratch delicate mirror coatings. Even small deposits can cause hot spots that damage expensive optical components.

Water temperature monitoring is essential – maintain between 15-25°C for optimal performance and longevity. Install temperature sensors in both inlet and outlet lines to ensure proper circulation. Consider chiller systems for high-duty-cycle applications where ambient temperatures might exceed recommended ranges during the summer months.

Operating current directly affects tube life, with manufacturers typically recommending maximum continuous currents of 20 mA for tubes up to 80W, 25 mA for 100W units, and 30 mA for higher-power models. Running at these maximums accelerates gas depletion and reduces lifespan significantly. For the longest life, operate 20-30% below maximum ratings when possible.

Annual replacement is recommended for commercial applications to maintain cutting speed and consistency, even if the tube continues operating. As tubes age, power output gradually decreases, requiring higher current settings to maintain performance. This creates a cycle of accelerating degradation that makes replacement economically sensible before complete failure.

Gas refilling services are available for extending tube life at 50-70% of the original cost, though success rates vary with tube condition and contamination levels. This option works best for tubes that haven’t been operated at excessive current levels or suffered physical damage. Evaluate based on remaining hours needed versus new tube costs.

Quality and Testing Standards

Manufacturing quality significantly impacts performance, reliability, and total cost of ownership. Understanding testing standards and quality indicators helps identify tubes that will deliver consistent results throughout their operational life.

Thermal stability testing ensures consistent output across temperature ranges encountered in real-world operation. Quality manufacturers subject tubes to temperature cycling between operating extremes while monitoring power output and beam quality parameters. This testing reveals manufacturing defects that might not appear during initial operation but could cause premature failure.

Stress-crack resistance testing involves rapid heating and cooling cycles that simulate the thermal stress of normal on-off operation. Glass tubes face particular challenges here, as temperature differentials between the inner bore and outer jacket can create stress points. Premium tubes use specialized glass formulations and controlled cooling processes during manufacture to enhance crack resistance.

Power output calibration is verified at multiple points during manufacturing to ensure rated specifications are met or exceeded. Reputable manufacturers test actual power output rather than simply calculating based on input current. This testing should include beam quality measurements and stability over extended operation periods.

Beam quality measurements, including M² factor and beam diameter consistency, determine cutting precision and focusing capability. Quality tubes maintain M² values between 1.0 and 1.5 across their power range, ensuring tight focus spots essential for detailed work. Beam diameter should remain consistent throughout the tube’s length to prevent hot spots or power loss.

Gas mixture purity and pressure affect both initial performance and longevity. Premium manufacturers use ultra-pure gases and carefully controlled mixing processes to ensure consistent results. Some tubes include proprietary catalysts that help maintain gas mixture stability over thousands of operating hours.

Two-year warranty coverage is standard for premium manufacturers, covering defects and premature failure under normal operating conditions. This coverage typically excludes damage from overcurrent operation, physical damage, or contamination from external sources. Extended warranty options may be available for critical applications where downtime costs are high.

Feiju Laser’s CO2 laser tubes undergo stringent quality control and testing to meet these high standards, providing customers with confidence in product reliability and performance.

Buying Considerations

Selecting the right CO2 laser tube involves balancing performance requirements against budget constraints while considering long-term operational costs. A systematic approach to evaluation ensures you get optimal value for your specific application needs.

Match tube power rating to your laser machine’s specifications and intended applications to avoid both underperformance and unnecessary expense. Oversized tubes waste money on capabilities you won’t use, while undersized units force operation at maximum current, reducing lifespan. Carefully evaluate your typical material thickness and desired cutting speeds to determine optimal power levels.

Consider tube length constraints based on your machine’s internal dimensions before adding items to your cart during the checkout process. A 150W tube at 1850mm length won’t fit in a machine designed for 80W 1250mm tubes, regardless of power supply compatibility. Measure carefully and verify clearances for both installation and future maintenance access.

Evaluate cooling requirements and ensure adequate water flow capacity exists in your current system. Higher-power tubes generate more heat and may require upgraded cooling systems, pumps, or chillers. Factor these additional costs into your purchase decision, especially when considering recurring or deferred purchase options that might spread payments over time.

Factor in replacement costs and availability of refurbishment services when making your initial selection. Some manufacturers offer gas refill services that can extend tube life economically, while others design tubes as consumable items. Understanding your options helps plan maintenance budgets and ensures continued operation.

Choose reputable manufacturers with an established warranty and technical support infrastructure. A lower price means little if you can’t get help when problems arise, or replacement parts aren’t available. Read warranty terms carefully, paying attention to what constitutes normal operation versus abuse that voids coverage.

Budget $200-$800 depending on power rating and tube construction type, with glass DC tubes at the lower end and RF metal-ceramic units commanding premium prices. Remember to calculate the total cost, including shipping, any required power supply modifications, and installation time, when comparing options. Some suppliers offer payment method flexibility, including deferred purchase plans that help manage cash flow for small shops.

Customers often find value in purchasing from suppliers who offer comprehensive support, including installation guidance, troubleshooting assistance, and readily available replacement parts. Submit questions about technical specifications before ordering to ensure compatibility with your specific laser systems.

Feiju Laser provides competitive pricing, flexible payment options, and dedicated customer support to help you through the entire buying process, from product selection to after-sales service.

When evaluating different models, pay attention to the tested specifications provided by manufacturers rather than marketing claims. Look for specific data on power output, beam quality, expected lifespan, and operating parameters. Check if the supplier offers order tracking and clear information about delivery dates listed in their system.

Consider the cancellation policy and return options, especially for custom or high-value orders. Ensure you understand the process for returns, warranty claims, and technical support before finalizing your purchase. Some manufacturers authorize local service centers, while others require factory returns, affecting downtime during service.

The journey from initial research to successful installation requires careful attention to technical details and supplier capabilities. Take time to enter all specifications correctly during the ordering process and ensure your payment method can handle the transaction amount. Many suppliers offer recurring order options for shops that replace tubes on regular schedules, potentially offering volume discounts.

Thanks to improved manufacturing standards and increased competition, today’s CO2 laser tubes offer better performance and longer lifespans than ever before. However, success still depends on proper selection, installation, and maintenance practices that protect your investment while maximizing productivity.

Conclusion: Choosing the Right CO2 Laser Tube for Optimal Performance

CO2 laser tubes form the foundation of successful cutting and engraving operations across industries, from small craft shops to large manufacturing facilities. Understanding the relationship between power ratings, material compatibility, and operational requirements enables informed decisions that optimize both performance and cost-effectiveness.

The key to success lies in matching tube specifications to your specific applications while maintaining proper operating conditions throughout the tube’s lifespan. Whether you’re processing wood, engraving acrylic, cutting leather, or working with paper and cardboard, the right combination of power, cooling, and maintenance ensures consistent results that keep customers satisfied and operations profitable.

Quality tubes from reputable manufacturers like Feiju Laser, properly installed and maintained, deliver thousands of hours of reliable service that justify their investment. By following the guidelines outlined in this guide, you’ll be equipped to select, install, and maintain CO2 laser tubes that support your business goals for years to come.